Are you gearing up for a career in Automation Technologist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automation Technologist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

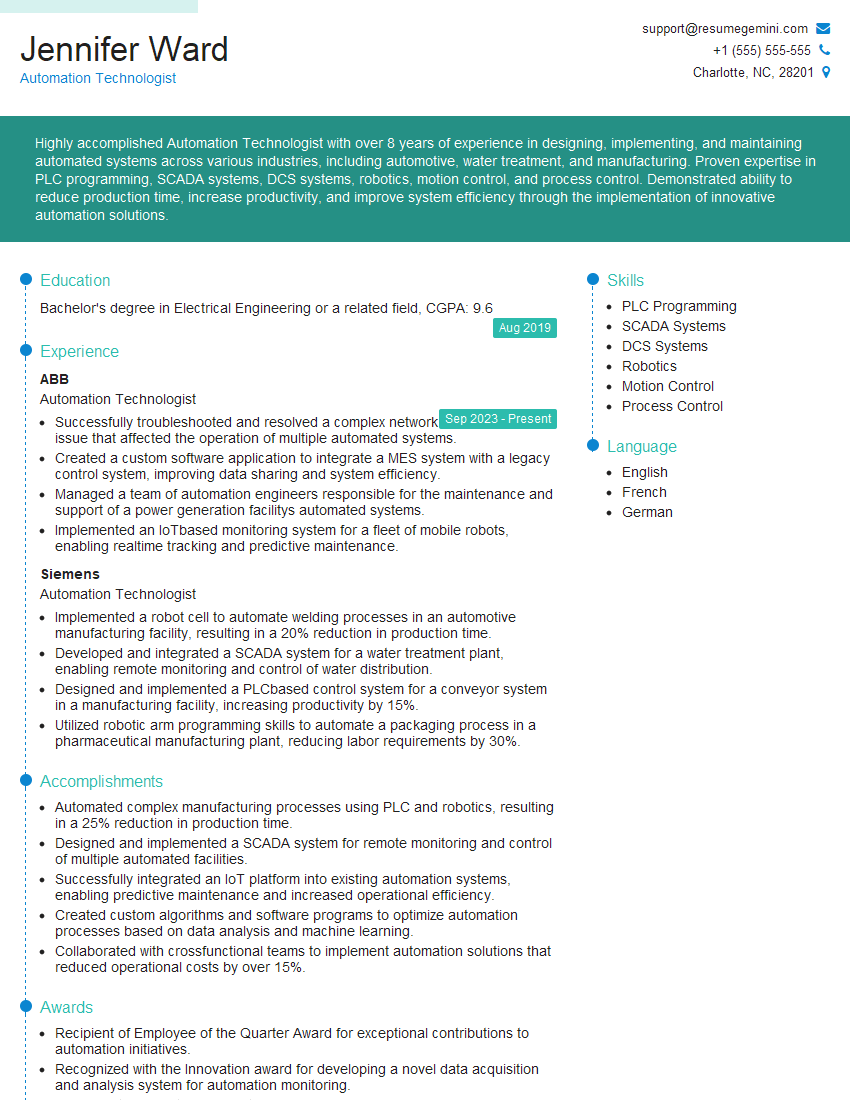

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automation Technologist

1. Describe the process of designing and developing automated industrial systems.

The process of designing and developing automated industrial systems involves the following steps:

- Define the system requirements. This includes identifying the specific tasks that the system must perform, the performance requirements, and the environmental conditions under which the system must operate.

- Select the appropriate hardware and software components. This includes choosing the right motors, sensors, controllers, and software to meet the system requirements.

- Design the system architecture. This involves determining the overall structure of the system, including the flow of materials, the location of components, and the communication network.

- Develop the automation program. This involves writing the software that will control the system’s operation.

- Implement the system. This involves installing the hardware and software, and configuring the system to meet the specific requirements of the application.

- Test and debug the system. This involves testing the system to ensure that it meets the performance requirements, and debugging any errors that are found.

- Maintain the system. This involves performing regular maintenance tasks to ensure that the system continues to operate reliably and efficiently.

2. Explain the difference between a PLC and a PAC.

PLC (Programmable Logic Controller)

- A PLC is a solid-state electronic device that uses a programmable memory to store instructions and execute functions such as logic, sequencing, timing, counting, and arithmetic operations.

- PLCs are designed for use in industrial environments and are typically used to control automated machinery and processes.

- PLCs are typically programmed using ladder logic, a graphical programming language that is easy to learn and use.

PAC (Programmable Automation Controller)

- A PAC is a more advanced type of controller that combines the functionality of a PLC with the capabilities of a personal computer.

- PACs are typically used in more complex applications, such as motion control, robotics, and data acquisition.

- PACs are typically programmed using a high-level programming language, such as C++ or Python.

3. What are the different types of sensors used in industrial automation?

There are many different types of sensors used in industrial automation, each with its own unique purpose and application.

- Position sensors measure the position of an object.

- Speed sensors measure the speed of an object.

- Force sensors measure the force applied to an object.

- Temperature sensors measure the temperature of an object.

- Pressure sensors measure the pressure of a fluid.

- Flow sensors measure the flow rate of a fluid.

- Level sensors measure the level of a liquid or solid in a container.

- Vibration sensors measure the vibration of an object.

- Image sensors capture images of objects.

4. What are the different types of actuators used in industrial automation?

There are many different types of actuators used in industrial automation, each with its own unique purpose and application.

- Electric actuators convert electrical energy into mechanical energy.

- Hydraulic actuators convert hydraulic energy into mechanical energy.

- Pneumatic actuators convert pneumatic energy into mechanical energy.

- Linear actuators produce linear motion.

- Rotary actuators produce rotary motion.

- Stepper motors produce precise, incremental motion.

- Servo motors produce precise, continuous motion.

5. What are the different types of communication networks used in industrial automation?

There are many different types of communication networks used in industrial automation, each with its own unique advantages and disadvantages.

- Ethernet is a high-speed, reliable network that is commonly used in industrial automation.

- PROFIBUS is a fieldbus network that is specifically designed for industrial automation.

- DeviceNet is a low-cost, easy-to-use network that is commonly used in small-scale industrial automation applications.

- CANbus is a robust, reliable network that is commonly used in automotive and other harsh environments.

- Wireless networks are becoming increasingly popular in industrial automation applications, as they offer the flexibility and convenience of wireless connectivity.

6. What are the different types of software tools used in industrial automation?

There are many different types of software tools used in industrial automation, each with its own unique purpose and application.

- CAD (Computer-Aided Design) software is used to create and modify 3D models of parts and assemblies.

- CAE (Computer-Aided Engineering) software is used to analyze and simulate the performance of parts and assemblies.

- CAM (Computer-Aided Manufacturing) software is used to generate toolpaths and other instructions for CNC machines.

- PLC programming software is used to develop and debug PLC programs.

- SCADA (Supervisory Control and Data Acquisition) software is used to monitor and control industrial processes.

- MES (Manufacturing Execution System) software is used to manage and optimize production processes.

7. What are the latest trends in industrial automation?

The following are some of the latest trends in industrial automation:

- The increasing use of robots and other automated systems.

- The adoption of artificial intelligence (AI) and machine learning (ML) in industrial automation.

- The growth of the Industrial Internet of Things (IIoT).

- The convergence of IT and OT (operational technology).

- The increasing focus on cybersecurity in industrial automation.

8. What are the challenges of industrial automation?

The following are some of the challenges of industrial automation:

- The high cost of implementing and maintaining automated systems.

- The need for skilled workers to operate and maintain automated systems.

- The potential for safety hazards associated with automated systems.

- The need to constantly update and upgrade automated systems to keep pace with technological advancements.

9. What are the benefits of industrial automation?

The following are some of the benefits of industrial automation:

- Increased productivity.

- Improved quality.

- Reduced costs.

- Increased safety.

- Improved sustainability.

10. What skills are required to be a successful automation technologist?

The following are some of the skills required to be a successful automation technologist:

- Strong technical skills in electrical, mechanical, and computer engineering.

- Experience with industrial automation systems and software.

- Strong problem-solving and analytical skills.

- Excellent communication and interpersonal skills.

- Ability to work independently and as part of a team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automation Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automation Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automation Technologists are responsible for designing, implementing, and maintaining automated systems in various industries. They play a crucial role in optimizing processes, improving efficiency, and reducing operational costs.

1. System Design and Development

Analyze business requirements and develop automated solutions to streamline processes and enhance productivity.

- Design and implement automation systems using various technologies (e.g., PLC, SCADA, DCS)

- Create custom software and hardware solutions to meet specific automation needs

2. System Integration

Integrate automated systems with existing infrastructure and equipment to ensure seamless operation.

- Connect automation systems to sensors, actuators, and other devices

- Develop interfaces to facilitate communication between automated systems and other systems (e.g., ERP, CRM)

3. System Maintenance and Troubleshooting

Monitor and maintain automated systems to ensure optimal performance and prevent downtime.

- Perform regular inspections and maintenance tasks

- Troubleshoot and resolve system issues to minimize disruptions

4. Process Optimization

Analyze automated systems and processes to identify areas for improvement and implement optimizations.

- Conduct performance assessments and identify bottlenecks

- Develop and implement solutions to enhance system efficiency and reduce costs

Interview Tips

To ace an interview for an Automation Technologist position, it’s essential to prepare thoroughly and demonstrate your expertise in the field. Here are some effective tips:

1. Research the Company and Role

Gather information about the company’s industry, products, and automation initiatives. Understand the specific requirements of the Automation Technologist role and how your skills align with them.

2. Highlight Your Automation Experience

Emphasize your hands-on experience in designing, implementing, and maintaining automated systems. Provide specific examples that showcase your technical proficiency and problem-solving abilities.

3. Present Your Problem-Solving Skills

Automation Technologists are often tasked with solving complex problems. Prepare to share examples of how you have identified and resolved automation issues in previous roles. Highlight your analytical thinking and troubleshooting skills.

4. Demonstrate Your Communication Skills

Automation Technologists often work with cross-functional teams. Showcase your ability to communicate technical concepts clearly and effectively to both technical and non-technical audiences.

Next Step:

Now that you’re armed with the knowledge of Automation Technologist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automation Technologist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini