Are you gearing up for a career in Automotive Maintenance Equipment Servicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automotive Maintenance Equipment Servicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

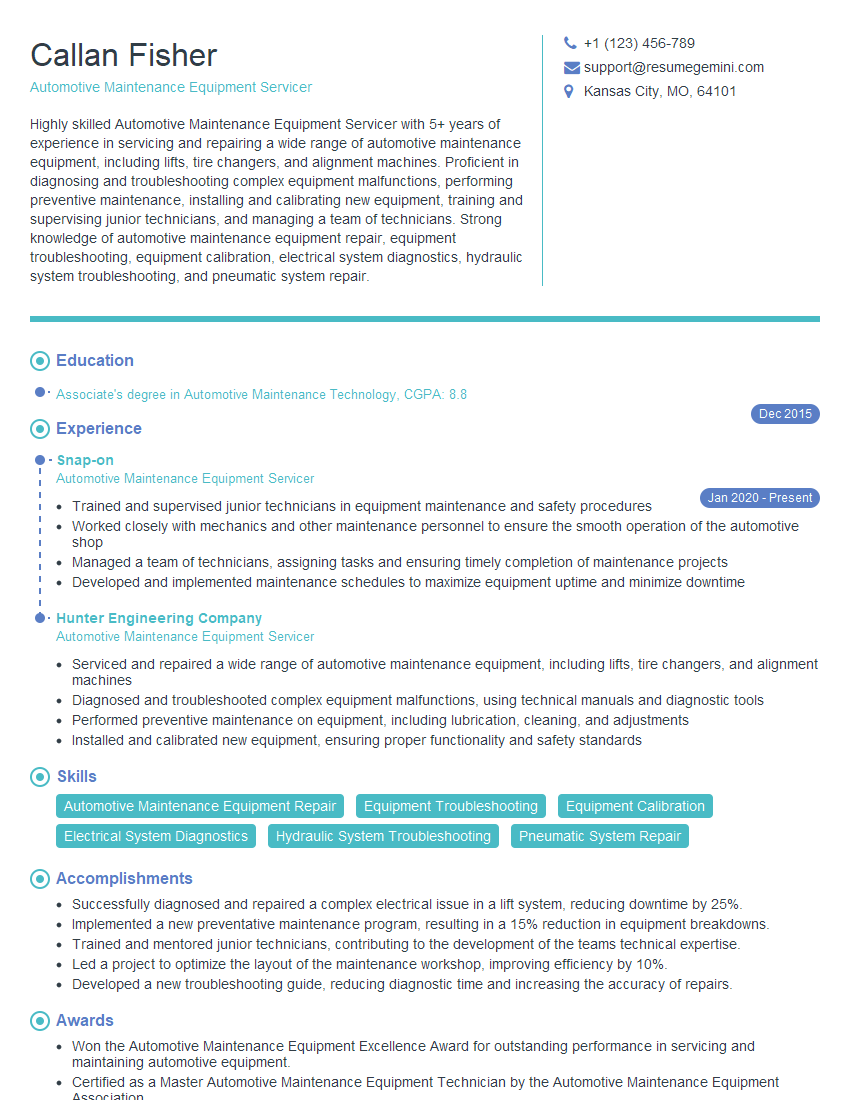

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automotive Maintenance Equipment Servicer

1. Describe the process of troubleshooting an automotive lift.

The process of troubleshooting an automotive lift involves the following steps:

- Identify the symptoms of the problem.

- Visually inspect the lift for any obvious damage or loose connections.

- Use a multimeter to test the electrical components of the lift, such as the motor, limit switches, and pressure sensors.

- Check the hydraulic system for any leaks or blockages.

- Follow the manufacturer’s troubleshooting guide to diagnose and repair the issue.

2. What is the proper procedure for calibrating an alignment machine?

Pre-Calibration Checks:

- Verify that the vehicle is properly positioned on the alignment machine.

- Check the tire pressure and adjust to the manufacturer’s specifications.

Calibration Procedure:

- Follow the manufacturer’s instructions for the specific alignment machine.

- Set the machine to the correct vehicle specifications.

- Calibrate the sensors using a known reference point.

Post-Calibration Checks:

- Perform a test alignment on a known good vehicle.

- Compare the results to the manufacturer’s specifications.

3. How do you service a tire changer?

Regular servicing of a tire changer is essential for optimal performance and longevity. The servicing process typically includes:

- Cleaning and greasing all moving parts.

- Inspecting and tightening bolts and connections.

- Calibrating the bead seater and inflation system.

- Replacing worn or damaged parts as needed.

4. What is the function of a wheel balancer, and how do you use it?

A wheel balancer is a machine used to detect and correct imbalances in wheels and tires. It consists of a rotating platform that spins the wheel while sensors measure the amount of vibration caused by any imbalance. The balancer then calculates the weight and location of the counterweights needed to correct the imbalance.

To use a wheel balancer, follow these steps:

- Mount the wheel on the balancer’s platform.

- Start the balancing cycle.

- The balancer will display the amount and location of the imbalance.

- Attach counterweights to the wheel as indicated by the balancer.

5. How do you inspect and replace an air filter on an air compressor?

Regular inspection and replacement of the air filter on an air compressor are essential for maintaining optimal performance and extending the life of the compressor. The inspection process typically involves:

- Visually inspecting the filter for any dirt or debris.

- Checking the filter’s pressure drop using a manometer.

- Replacing the filter if it is dirty or restricted.

To replace an air filter, follow these steps:

- Turn off the compressor and disconnect the power supply.

- Locate the air filter housing and remove the cover.

- Remove the old filter and replace it with a new one.

- Reinstall the cover and reconnect the power supply.

6. What are the common causes of a hydraulic leak in a lift, and how do you identify them?

Common causes of a hydraulic leak in a lift include:

- Damaged or loose hoses or fittings.

- Worn or damaged seals or O-rings.

- Cracked or damaged hydraulic cylinders.

To identify the source of a hydraulic leak, follow these steps:

- Visually inspect the entire hydraulic system for any visible leaks.

- Use a flashlight to check for leaks in hard-to-see areas.

- Listen for any hissing or dripping sounds that may indicate a leak.

7. How do you troubleshoot an electrical problem on an alignment machine?

Troubleshooting an electrical problem on an alignment machine requires a systematic approach:

- Start by checking the power source to ensure that the machine is receiving power.

- Next, inspect the wiring and connections for any loose or damaged wires.

- Use a multimeter to test the voltage and continuity of the electrical components.

- If a specific component is found to be faulty, replace it.

- Finally, recalibrate the alignment machine to ensure accurate measurements.

8. What are the different types of automotive lifts, and what are their advantages and disadvantages?

The different types of automotive lifts include:

- Two-post lifts: Advantages: compact size, easy to install, suitable for small spaces. Disadvantages: limited lifting height, not suitable for heavy vehicles.

- Four-post lifts: Advantages: stable, high lifting capacity, suitable for larger vehicles. Disadvantages: require more space, more expensive than two-post lifts.

- Scissor lifts: Advantages: low profile, suitable for low-clearance vehicles. Disadvantages: limited lifting height, not suitable for heavy vehicles.

- Mobile lifts: Advantages: portable, easy to move around the shop. Disadvantages: limited lifting capacity, not suitable for heavy-duty work.

9. How do you maintain and calibrate a torque wrench?

To maintain and calibrate a torque wrench, follow these steps:

- Clean the wrench regularly and apply a light coat of oil to the moving parts.

- Calibrate the wrench annually or more frequently if it is heavily used.

- To calibrate the wrench, use a torque calibration tester and follow the manufacturer’s instructions.

10. What are the safety regulations that must be followed when working with automotive maintenance equipment?

Important safety regulations for working with automotive maintenance equipment include:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Ensure that the equipment is properly maintained and calibrated.

- Follow the manufacturer’s instructions for safe operation and maintenance.

- Never work on or under a raised vehicle without proper support.

- Be aware of your surroundings and potential hazards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automotive Maintenance Equipment Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automotive Maintenance Equipment Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automotive Maintenance Equipment Servicers are responsible for maintaining, troubleshooting, and repairing automotive maintenance equipment such as lifts, tire changers, and wheel aligners. They must be able to diagnose problems quickly and efficiently, and have a strong understanding of the mechanical and electrical systems of automotive maintenance equipment.

1. Maintenance

Servicers perform routine maintenance on automotive maintenance equipment, such as

- Lubricating moving parts

- Inspecting for wear and tear

- Replacing worn or damaged parts

2. Troubleshooting

Servicers troubleshoot automotive maintenance equipment when it malfunctions. They must be able to identify the source of the problem and determine the best course of action for repair.

- Using diagnostic tools to identify problems

- Repairing or replacing faulty components

3. Repair

Servicers repair automotive maintenance equipment that has been damaged or malfunctioning. They must be able to perform a variety of repairs, including

- Replacing bearings

- Rebuilding hydraulic cylinders

- Wiring electrical systems

4. Safety

Servicers must follow all safety regulations when working on automotive maintenance equipment. They must be aware of the potential hazards of the equipment and take precautions to avoid injury.

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Working in a safe environment

Interview Tips

Preparing for an interview for an Automotive Maintenance Equipment Servicer position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. Understanding the company’s culture and values will help you answer questions about why you are interested in working there. Researching the position will help you understand the specific skills and experience the interviewer is looking for.

- Visit the company website

- Read articles and reviews about the company

- Review the job description

2. Practice answering common interview questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions ahead of time so that you can deliver your answers confidently and concisely. You can also prepare for specific questions related to your skills and experience.

- Use the STAR method to answer questions

- Focus on your skills and experience that are relevant to the position

- Be confident and articulate

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience in automotive maintenance equipment service. Be prepared to discuss your skills and experience in detail. You can also highlight any specific projects or accomplishments that you are particularly proud of.

- Provide specific examples of your work

- Quantify your accomplishments whenever possible

- Be enthusiastic and passionate about your work

4. Ask questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is a great opportunity to learn more about the company and the position. It also shows the interviewer that you are engaged and interested in the job.

- Ask questions about the company culture

- Ask questions about the specific role and responsibilities

- Ask questions about the company’s growth plans

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automotive Maintenance Equipment Servicer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.