Are you gearing up for an interview for a Aviation Boatswain’s Mate, Launching & Recovery Equipment position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Aviation Boatswain’s Mate, Launching & Recovery Equipment and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

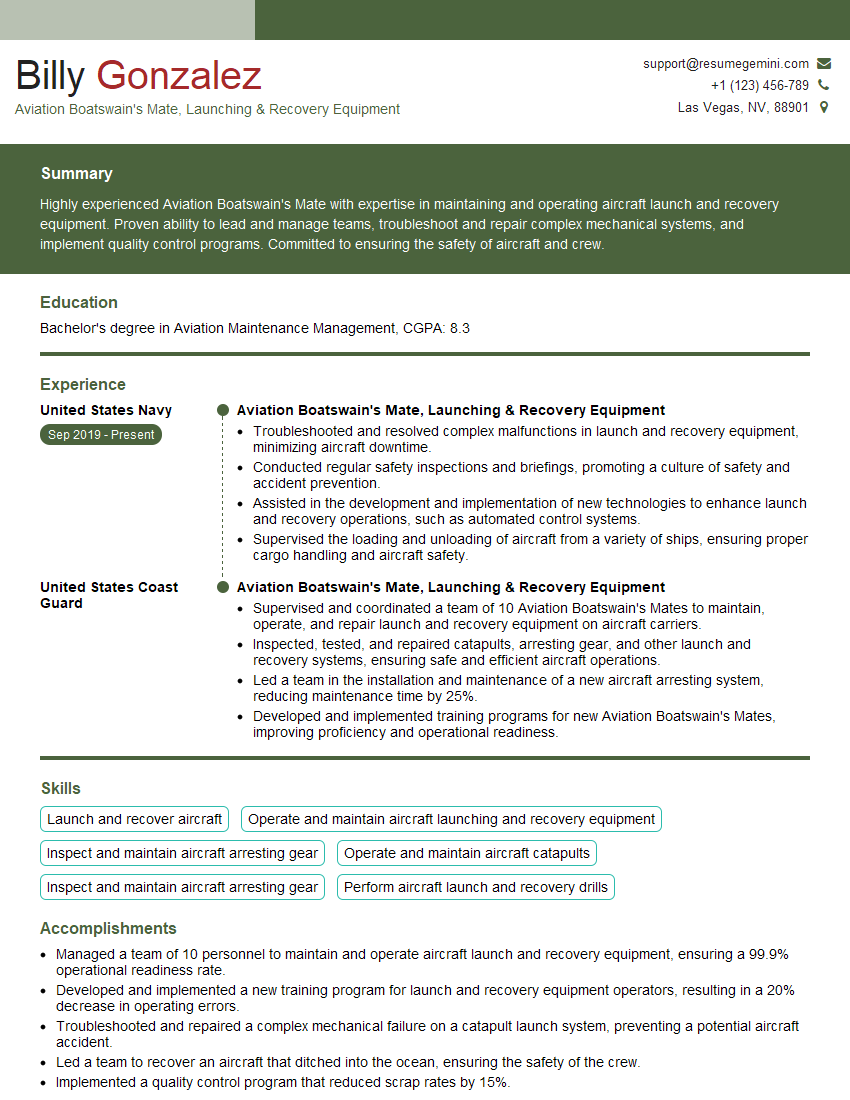

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aviation Boatswain’s Mate, Launching & Recovery Equipment

1. Explain the steps involved in conducting a complete mechanical inspection of the arresting gear system?

In conducting a complete mechanical inspection of the arresting gear system, I follow a comprehensive procedure that ensures all critical components are thoroughly examined for functionality, wear, and damage.

- Pre-inspection: Gather necessary tools, technical manuals, and personal protective equipment (PPE).

- Visual inspection: Examine the entire system, including the launch bar, bridle arrestor, energy-absorbing unit, and hydraulic components, for any visible signs of damage, corrosion, or leaks.

- Detailed inspection: Use specialized tools, such as micrometers and torque wrenches, to measure and check the condition of key components, such as the piston rod, seals, and bearings.

- Functional testing: Perform operational tests to verify the proper functioning of the system, including hydraulic pressure, tension, and release mechanisms.

- Documentation: Record all findings, measurements, and any required repairs or adjustments in a detailed inspection report.

2. Describe the procedures for operating the launch and recovery equipment in various weather conditions, including high winds, rain, and icing?

Handling High Winds:

- Monitor wind speed and direction, ensuring compliance with operational limits.

- Adjust launch and recovery procedures, such as using higher launch angles or slower recovery speeds.

Operating in Rain:

- Inspect equipment thoroughly for any water ingress or electrical hazards.

- Employ proper waterproofing techniques to protect sensitive components.

Managing Icing Conditions:

- Remove ice and snow from equipment surfaces using approved methods.

- Apply anti-icing or de-icing agents as per manufacturer’s guidelines.

- Ensure equipment is properly heated and insulated to prevent freezing.

3. How do you troubleshoot and repair hydraulic system malfunctions on the arresting gear?

To troubleshoot and repair hydraulic system malfunctions on the arresting gear, I follow a systematic approach:

- Identify the malfunction: Observe symptoms, check gauges, and perform diagnostic tests to determine the source of the problem.

- Isolating the problem: Disconnect or bypass components as necessary to isolate the faulty part.

- Repair or replacement: Based on the diagnosis, repair or replace damaged components, such as seals, hoses, or valves.

- Test and verify: Conduct thorough testing to ensure the repaired system meets operational specifications.

4. What are the safety precautions that must be observed when working on or around the arresting gear?

When working on or around the arresting gear, strict adherence to safety precautions is paramount:

- Wear appropriate PPE, including coveralls, safety glasses, and hearing protection.

- Ensure the system is de-energized and isolated before performing any maintenance.

- Use proper lockout/tagout procedures to prevent accidental activation.

- Follow established operating procedures and consult technical manuals for specific safety guidelines.

- Be aware of the potential for stored energy in the system and handle components accordingly.

5. How do you maintain and calibrate the tension indicator system on the launch bar?

To maintain and calibrate the tension indicator system on the launch bar, I perform the following steps:

- Inspect the system for any damage or corrosion that could affect accuracy.

- Use a certified load cell to apply a known tension to the launch bar.

- Adjust the tension indicator until its reading matches the applied load.

- Verify the calibration using multiple load points and ensure the system meets specified tolerances.

- Document the calibration results and maintain records for traceability.

6. Describe the procedures for inspecting and maintaining the bridle arrestor system?

Inspecting and maintaining the bridle arrestor system involves a comprehensive approach:

- Visual inspection: Examine the arresting hook, bridle, and energy-absorbing unit for any signs of damage or wear.

- Detailed inspection: Use specialized tools to measure and check critical dimensions, such as hook gap and bridle tension.

- Operational testing: Conduct functional tests to verify the proper operation of the arresting mechanism, including hook engagement and energy absorption.

- Lubrication and cleaning: Lubricate moving parts as per manufacturer’s specifications and clean the system to prevent corrosion.

7. How do you handle and store explosive bolts used in the launch system?

Handling and storage of explosive bolts in the launch system require strict adherence to safety protocols:

- Wear appropriate PPE and follow established explosive handling procedures.

- Store explosive bolts in a designated, secure, and climate-controlled magazine.

- Maintain accurate inventory records and ensure bolts are properly labeled and accounted for.

- Inspect bolts regularly for any signs of damage or deterioration.

- Dispose of expired or damaged bolts through authorized channels, following environmental and safety regulations.

8. What are the critical maintenance requirements for the energy-absorbing unit on the arresting gear?

Ensuring optimal performance of the energy-absorbing unit on the arresting gear requires regular and thorough maintenance:

- Inspect the unit for any signs of damage, corrosion, or fluid leaks.

- Check hydraulic fluid levels and condition, and replace as necessary.

- Lubricate moving parts and ensure proper alignment and clearances.

- Conduct functional testing to verify the unit’s ability to absorb and dissipate energy effectively.

- Follow manufacturer’s recommended maintenance schedules and replace components as required.

9. How do you prioritize maintenance tasks and allocate resources to ensure the operational readiness of the launch and recovery equipment?

Prioritizing maintenance tasks and allocating resources effectively is crucial for maintaining operational readiness:

- Assess the criticality of each maintenance task based on potential impact on operations.

- Use a risk-based approach to identify tasks that require immediate attention.

- Consider equipment usage, environmental factors, and manufacturer’s recommendations when scheduling maintenance.

- Allocate resources, including personnel, tools, and materials, based on task complexity and urgency.

- Monitor maintenance progress and adjust schedules as needed to ensure timely completion.

10. Describe your experience in training and supervising junior personnel on the operation and maintenance of launch and recovery equipment.

Throughout my career, I have actively engaged in training and supervising junior personnel:

- Training: Developed and delivered training programs on equipment operation, maintenance procedures, and safety protocols.

- Mentoring: Provided guidance and support to junior personnel, fostering their technical skills and professional development.

- Evaluation: Assessed trainees’ progress through practical exercises and written tests to ensure proficiency.

- Supervision: Supervised junior personnel during maintenance tasks, ensuring adherence to procedures and quality standards.

- Delegation: Gradually delegated responsibilities to junior personnel as they gained experience and demonstrated competence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aviation Boatswain’s Mate, Launching & Recovery Equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aviation Boatswain’s Mate, Launching & Recovery Equipment‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Aviation Boatswain’s Mate is responsible for operating and maintaining launch, recovery, and handling equipment such as catapults, arresting gear, and barricades on aviation ships. They help ensure the safe and efficient launch and landing of aircraft. Primary responsibilities include:

1. Operating Catapults

Aviation Boatswain’s Mates operate catapults to launch aircraft from aircraft carriers. They must have a thorough understanding of the catapult system, including its mechanics, safety procedures, and operating limits.

- Preparing catapults for launch

- Monitoring catapult operations

- Troubleshooting and repairing catapult systems

2. Operating Arresting Gear

Aviation Boatswain’s Mates operate arresting gear to stop aircraft on aircraft carriers. They must have a thorough understanding of the arresting gear system, including its mechanics, safety procedures, and operating limits.

- Preparing arresting gear for landing

- Monitoring arresting gear operations

- Troubleshooting and repairing arresting gear systems

3. Maintaining Equipment

Aviation Boatswain’s Mates are responsible for maintaining all launch and recovery equipment, including catapults, arresting gear, and barricades. They must have a thorough understanding of the equipment, including its maintenance schedules, procedures, and safety requirements.

- Performing scheduled maintenance on equipment

- Inspecting equipment for damage

- Repairing and replacing equipment as needed

4. Training Sailors

Aviation Boatswain’s Mates are responsible for training Sailors on the operation and maintenance of launch and recovery equipment. They must have a strong understanding of the equipment, as well as effective teaching skills.

- Developing and delivering training programs

- Evaluating Sailors on their knowledge and skills

- Mentoring and advising Sailors

Interview Tips

To ace your interview for an Aviation Boatswain’s Mate position, follow these tips:

1. Research the Position and Company

Before your interview, research the Aviation Boatswain’s Mate position and the company you are applying to. This will give you a good understanding of the job responsibilities and the company culture. You will be able to answer questions intelligently and show that you are genuinely interested in the position.

- Visit the company’s website

- Read about the Aviation Boatswain’s Mate position

- Talk to people who work in the field

2. Practice Your Answers

Once you have a good understanding of the position and company, practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common questions you may be asked include:

- Tell me about your experience with launch and recovery equipment.

- What are your strengths and weaknesses as an Aviation Boatswain’s Mate?

- Why are you interested in working for this company?

3. Be Enthusiastic and Professional

During your interview, be enthusiastic and professional. Show the interviewer that you are passionate about the job and that you are committed to the company. Dress appropriately, arrive on time, and be respectful of the interviewer’s time.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Be yourself

4. Ask Questions

At the end of your interview, ask the interviewer questions about the position and company. This shows that you are interested in the job and that you are taking the interview seriously. Some good questions to ask include:

- What are the biggest challenges facing Aviation Boatswain’s Mates today?

- What is the company’s culture like?

- What are the opportunities for advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aviation Boatswain’s Mate, Launching & Recovery Equipment interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!