Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aviation Metalsmith interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aviation Metalsmith so you can tailor your answers to impress potential employers.

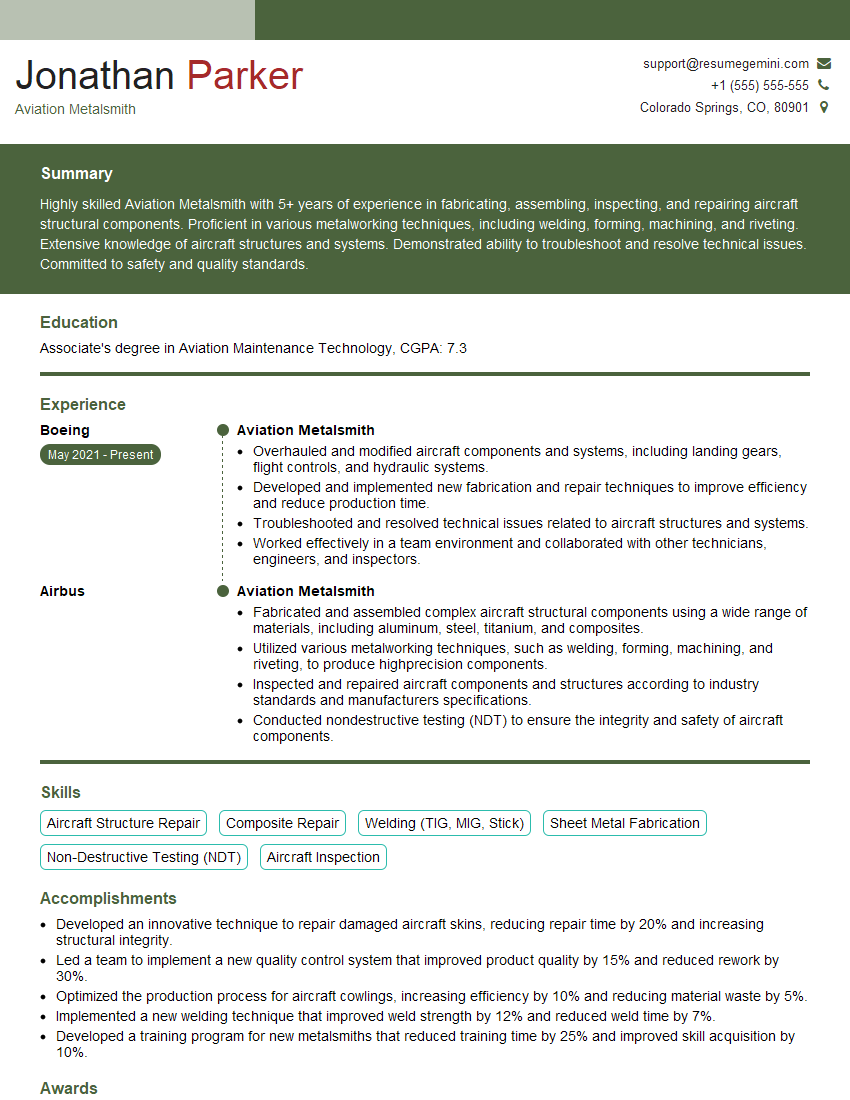

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aviation Metalsmith

1. Explain the process of forming and bending aircraft parts?

The process of forming and bending aircraft parts involves shaping and manipulating metal sheets and extrusions to create the desired shape. This can be achieved through various techniques, including:

- Hand forming using hammers, mallets, and dollies for small-scale shaping.

- Machine forming using press brakes, roll forming machines, and stretch forming machines for larger and more complex shapes.

- Heat treating to soften the metal and make it more pliable for forming and bending.

- Annealing to relieve internal stresses and prevent cracking during the forming process.

2. Describe the different types of welding processes used in aircraft manufacturing?

Various welding processes are used in aircraft manufacturing, each suited for specific applications and materials. Some common techniques include:

Gas Tungsten Arc Welding (GTAW)

- Uses a tungsten electrode and a shielding gas to weld thin metal sheets and create precise welds.

- Produces high-quality, strong welds with minimal distortion.

Gas Metal Arc Welding (GMAW)

- Employs a consumable wire electrode and a shielding gas to weld thicker metals.

- Offers higher deposition rates and faster welding speeds.

Resistance Spot Welding

- Uses two copper electrodes to generate heat and pressure, fusing metal sheets together.

- Typically used for joining thin aluminum sheets.

3. What are the key considerations when selecting materials for aircraft parts?

When selecting materials for aircraft parts, several key considerations must be taken into account, including:

- Strength-to-weight ratio: Aircraft parts must be strong enough to withstand the rigors of flight while minimizing weight.

- Corrosion resistance: Materials must be resistant to corrosion caused by exposure to harsh environmental conditions.

- Formability: The material should be capable of being formed and shaped into the desired part geometry.

- Availability and cost: The material must be readily available and cost-effective for production.

4. Explain the importance of quality control in aircraft manufacturing?

Quality control is paramount in aircraft manufacturing to ensure the safety and reliability of aircraft. It involves rigorous inspection and testing procedures throughout the production process, including:

- Non-destructive testing (NDT) techniques such as ultrasonic testing (UT) and radiographic testing (RT) to detect defects and ensure structural integrity.

- Dimensional inspections to verify that parts meet the required tolerances.

- Material testing to ensure the material properties meet specifications.

- Compliance audits to verify adherence to industry standards and regulations.

5. Describe the role of composites in modern aircraft construction?

Composites play a significant role in modern aircraft construction due to their unique properties:

- High strength-to-weight ratio: Composites are lighter than traditional materials like aluminum, allowing for weight reduction.

- Enhanced durability: Composites are resistant to corrosion and fatigue, extending the lifespan of aircraft parts.

- Design flexibility: Composites can be molded into complex shapes, enabling aerodynamic designs and structural efficiency.

- Reduced manufacturing time: Composites can be manufactured using automated processes, reducing production lead times.

6. Explain the principles of structural analysis used in aircraft design?

Structural analysis is crucial in aircraft design to ensure the strength and stability of the aircraft structure. It involves:

- Finite element analysis (FEA) to simulate structural behavior under various loading conditions.

- Stress analysis to determine the distribution of stresses within the structure.

- Fatigue analysis to predict the lifespan of aircraft components under repeated loads.

- Buckling analysis to assess the stability of structures under compressive loads.

7. Describe the different types of aircraft maintenance inspections and their purpose?

Aircraft maintenance inspections are classified into various types based on their scope and frequency:

- A-Check: A routine inspection performed every 500-1,000 flight hours to identify and resolve minor issues.

- B-Check: A more comprehensive inspection conducted every 2,000-4,000 flight hours, involving detailed checks of major systems.

- C-Check: A major inspection performed every 12-24 months, including a complete disassembly and inspection of the aircraft.

- D-Check: The most extensive inspection, typically conducted every 6-10 years, involving a complete teardown and overhaul of the aircraft.

8. Explain the process of aircraft modification and the regulatory considerations involved?

Aircraft modification involves altering the design or configuration of an aircraft to improve performance or functionality. It requires careful planning and execution, adhering to the following steps:

- Design and engineering: Developing the modification design and obtaining necessary approvals.

- Fabrication and installation: Manufacturing and installing the modification on the aircraft.

- Testing and certification: Conducting flight tests and obtaining regulatory approval for the modification.

- Documentation and maintenance: Updating aircraft maintenance manuals and records to reflect the modification.

9. Describe the role of advanced technologies in modern aviation manufacturing?

Advanced technologies are transforming aviation manufacturing, enabling greater efficiency, precision, and innovation. Some key technologies include:

- Additive manufacturing (3D printing): Creating complex parts directly from digital models, reducing lead times and waste.

- Automated assembly: Using robots and automated systems to streamline assembly processes, improving accuracy and productivity.

- Virtual reality (VR) and augmented reality (AR): Enhancing training and design visualization, improving collaboration and efficiency.

- Artificial intelligence (AI): Optimizing production processes, predicting maintenance needs, and enhancing safety.

10. Discuss the challenges and opportunities in the aviation industry for Aviation Metalsmiths?

The aviation industry presents both challenges and opportunities for Aviation Metalsmiths:

Challenges:

- Rapid technological advancements requiring continuous training and skill development.

- Stringent safety regulations and quality standards, demanding precise and diligent workmanship.

- Physical demands and potential exposure to hazardous materials.

Opportunities:

- Growing demand for skilled Aviation Metalsmiths due to the increasing number of aircraft in operation.

- Job stability and career advancement opportunities within the aviation sector.

- Contribution to the safety and efficiency of air travel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aviation Metalsmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aviation Metalsmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aviation Metalsmiths play a crucial role in the aviation industry, working with various metals to ensure the safety and functionality of aircraft. Their key responsibilities include:1. Fabrication and Assembly

Fabricating and assembling metal parts for aircraft structures, such as wings, fuselages, and engine nacelles.

- Cutting, shaping, and forming metal sheets, tubes, and extrusions using specialized tools and techniques.

- Assembling parts using rivets, bolts, and welding.

2. Structural Repair

Inspecting, repairing, and overhauling metal aircraft components to ensure structural integrity.

- Identifying and diagnosing damaged or defective metal parts.

- Repairing or replacing damaged sections using various methods, including welding, riveting, and patching.

3. Sheet Metal Fabrication

Working with sheet metal to create custom components, such as panels, ducts, and brackets.

- Using precision tools to cut, form, and weld sheet metal into desired shapes.

- Ensuring accuracy and compliance with specified dimensions and tolerances.

4. Quality Control

Inspecting and testing fabricated and repaired metal components to verify their quality and compliance with industry standards.

- Using instruments and equipment to measure dimensions, inspect for defects, and verify material properties.

- Documenting inspection results and maintaining quality records.

Interview Tips

To ace the interview for an Aviation Metalsmith position, candidates should consider the following tips:1. Research the Company and Position

Show that you’ve taken the time to learn about the company, its products or services, and the specific role you’re applying for.

- Visit the company website and LinkedIn page.

- Review the job description thoroughly.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the key responsibilities of the Aviation Metalsmith role.

- Provide specific examples of your work in fabrication, assembly, repair, or quality control.

- Quantify your accomplishments whenever possible.

3. Showcase Safety and Quality Consciousness

In the aviation industry, safety and quality are paramount. Highlight your commitment to these principles.

- Describe your understanding of aircraft safety regulations and standards.

- Emphasize your attention to detail and thoroughness in your work.

4. Prepare for Technical Questions

Be prepared to answer technical questions about metalworking processes, materials, and aviation principles.

- Review common metalworking techniques, such as welding, riveting, and sheet metal fabrication.

- Familiarize yourself with aircraft materials, such as aluminum, steel, and composites.

5. Practice Your Answers

Practice answering common interview questions and use the STAR method (Situation, Task, Action, Result).

- Prepare examples of your work that demonstrate your skills and abilities.

- Practice delivering your answers clearly and concisely.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aviation Metalsmith interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.