Are you gearing up for an interview for a Axminster Weaver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Axminster Weaver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

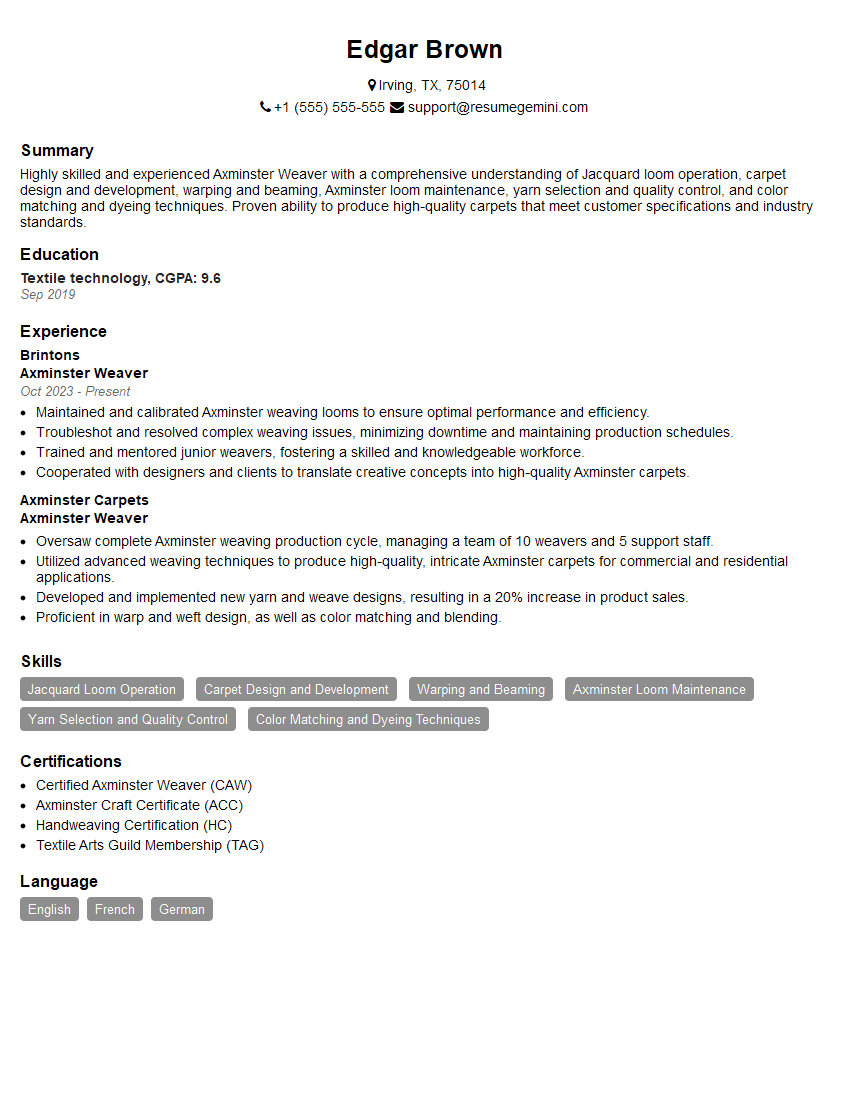

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Axminster Weaver

1. How do you select the yarn for weaving?

To select the yarn for weaving, I consider several key factors:

- Fiber content: I assess the desired properties of the final fabric, such as durability, comfort, and moisture wicking, and select yarns made from appropriate fibers (e.g., cotton, wool, silk, linen).

- Yarn count: I determine the thickness of the yarn needed to achieve the desired fabric weight and texture.

- Yarn twist: I consider the amount of twist in the yarn, as it affects the fabric’s drape, strength, and texture.

- Color and pattern: I choose yarns that complement the desired design and color scheme of the fabric.

- Supplier reliability: I ensure that I source yarns from reputable suppliers who can provide consistent quality and timely delivery.

2. What are the different weaving techniques you use and when do you use each one?

Plain weave

- Interlacing each warp and weft thread alternately, creating a simple and durable fabric.

- Suitable for a wide range of fabrics, from bed linens to canvas.

Twill weave

- Interlacing warp and weft threads in a diagonal pattern, resulting in a fabric with a distinct texture and increased durability.

- Often used for workwear, upholstery, and fabrics with a slightly heavier weight.

Satin weave

- Interlacing warp and weft threads in a way that creates a smooth, lustrous surface with few visible interlacements.

- Suitable for fabrics requiring a luxurious appearance, such as silk and satin.

3. How do you prepare the loom for weaving?

- Warping: I measure and cut the warp threads to the desired length and wind them onto the warp beam.

- Sleying: I thread the warp threads through the heddles and reed according to the desired pattern.

- Beaming: I transfer the warped threads onto the loom’s main beam.

- Tying up: I connect the heddles to the treadles, defining the weave pattern.

- Winding the weft: I prepare the weft yarn on bobbins or shuttles ready for weaving.

4. What are the common problems that can occur during weaving and how do you troubleshoot them?

Warp breakage

- Causes: Excessive tension, poor yarn quality, or incorrect threading.

- Solutions: Adjust tension, replace weak yarns, check threading, and lubricate the loom.

Weft breakage

- Causes: Insufficient weft tension, incorrect shuttle size, or yarn defects.

- Solutions: Adjust weft tension, use appropriate shuttle, and inspect yarn for flaws.

Tension issues

- Causes: Incorrect tension settings or uneven warping.

- Solutions: Adjust tension knobs, re-warp the loom, or check for friction points.

5. How do you ensure the quality of your woven fabrics?

- Pre-weaving: Inspect yarn quality, tension, and threading accuracy.

- During weaving: Monitor fabric formation, tension, and any potential defects.

- Post-weaving: Inspect finished fabric for defects, measure shrinkage, and conduct strength tests.

- Documentation: Maintain records of yarn specifications, weaving parameters, and quality control checks.

6. What are the different types of looms you have experience working with?

- Handloom: Traditional manual loom used for small-scale production and intricate designs.

- Power loom: Mechanized loom that automates the weaving process, allowing for increased speed and efficiency.

- Jacquard loom: Advanced loom used for creating complex patterns and incorporating intricate designs.

7. How do you handle the preparation of warp and weft yarns for weaving?

Warp preparation

- Warping: Winding the warp threads onto the warp beam, ensuring correct tension and length.

- Sizing: Applying a coating to the warp threads to increase strength and reduce breakage.

- Sleying: Threading the warp threads through the heddles and reed.

Weft preparation

- Winding: Winding the weft yarn onto bobbins or shuttles.

- Quilling: Creating small bobbins of weft yarn for use in shuttles.

8. What is the importance of proper tension control in weaving?

- Warp tension: Ensures uniform fabric formation, prevents breakage, and affects the fabric’s texture.

- Weft tension: Impacts the density of the fabric, prevents weft slippage, and affects the fabric’s drape.

- Balanced tension: Maintains the desired fabric structure, prevents puckering, and ensures overall quality.

9. Can you explain the concept of a loom shed and how it affects the weaving process?

- Loom shed: The space created between the warp and weft threads when the heddles are raised or lowered.

- Shed geometry: The shape and dimensions of the loom shed, which determines the weave pattern.

- Balanced shed: A symmetrical shed ensures proper interlacing of warp and weft threads, preventing fabric defects.

10. What are the key factors to consider when designing a weaving pattern?

- Fabric end-use: The intended application of the fabric influences the choice of weave pattern, fiber, and yarn count.

- Yarn characteristics: The properties of the yarn (e.g., thickness, twist, texture) affect the appearance and handle of the fabric.

- Loom capabilities: The type of loom and its shedding mechanism limit the complexity of the weave patterns that can be created.

- Aesthetic considerations: The desired look and feel of the fabric guides the selection of colors, textures, and patterns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Axminster Weaver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Axminster Weaver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Axminster Weavers are responsible for the production of Axminster carpets, a type of high-quality, hand-woven carpet. The role involves various tasks, including:

1. Yarn Preparation

Preparing the yarn, which includes selecting the appropriate wool or other fibers, dyeing the yarn, and winding it onto bobbins.

2. Warp Beam Winding

Winding the prepared yarn onto a warp beam, which is then used to create the foundation of the carpet.

3. Loom Operation

Operating the Axminster loom, which involves using a series of needles to insert the yarn into the warp beam, creating the carpet’s pattern.

4. Carpet Finishing

Inspecting and finishing the carpet, which may include shearing, trimming, and applying a backing.

Interview Tips

To ace the job interview for an Axminster Weaver position, consider these tips:

1. Research the Company and Role

Before the interview, research the company and the specific Axminster Weaver role. Understanding the company’s history, values, and the responsibilities of the position will show the interviewer that you are genuinely interested in the opportunity.

2. Highlight Relevant Skills

Emphasize your skills and experience relevant to the job. For example, highlight your proficiency in yarn preparation, loom operation, or carpet finishing. Mention specific examples to demonstrate your capabilities.

3. Practice and Prepare Answers

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Practice your answers to deliver them confidently and clearly.

4. Dress Appropriately

First impressions matter. Dress professionally and neatly to show the interviewer that you are taking the interview seriously.

5. Ask Questions

During the interview, ask thoughtful questions to show your engagement and interest in the role. This could include questions about the company’s commitment to sustainability or the opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Axminster Weaver interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Axminster Weaver positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini