Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted B-Operator (Recovery and Combination Boiler Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

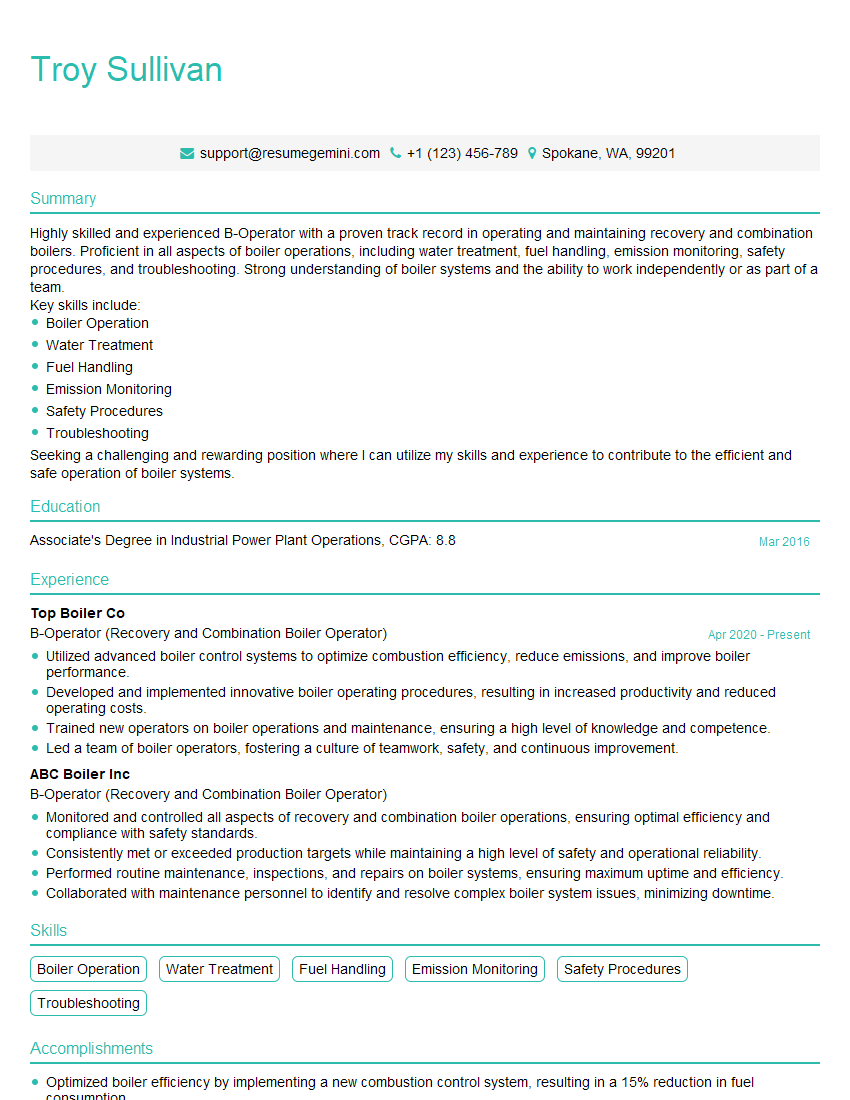

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For B-Operator (Recovery and Combination Boiler Operator)

1. Could you elaborate on the primary responsibilities of a B-Operator (Recovery and Combination Boiler Operator)?

As a B-Operator (Recovery and Combination Boiler Operator), I am entrusted with the following key responsibilities:

- Monitoring and controlling the operation of recovery and combination boilers to ensure efficient and safe steam production.

- Observing and adjusting boiler settings, including fuel flow, air flow, feedwater flow, and steam pressure, to maintain optimal combustion and steam generation.

- Conducting regular inspections, tests, and maintenance procedures on boilers and associated equipment to identify and address potential issues promptly.

- Responding to system malfunctions, equipment breakdowns, and emergency situations by taking appropriate corrective actions.

- Adhering to safety protocols, environmental regulations, and operating procedures to ensure a safe and compliant work environment.

2. How would you troubleshoot a situation where the boiler is not generating sufficient steam pressure?

Problem Analysis

- Inspect the fuel supply system for any blockages or restrictions.

- Check the air intake system for any obstructions or leaks.

- Examine the feedwater system for proper flow rate and water quality.

- Review boiler settings to ensure they are optimized for steam production.

Corrective Actions

- Adjust fuel flow or air flow to achieve optimal combustion.

- Clean or replace fuel filters or air filters as necessary.

- Increase feedwater flow rate or adjust water treatment chemicals to improve water quality.

- Fine-tune boiler settings, such as steam pressure setpoint or fuel-to-air ratio, to enhance steam generation.

3. Explain the importance of maintaining proper water chemistry in a boiler system.

- Prevents Corrosion and Scale Formation: Proper water chemistry inhibits the formation of scale and corrosion, which can damage boiler components and reduce efficiency.

- Optimizes Boiler Performance: Balanced water chemistry allows for efficient heat transfer, reducing fuel consumption and maintaining boiler capacity.

- Extends Equipment Lifespan: By minimizing corrosion and scale, proper water chemistry increases the lifespan of boiler components and reduces the frequency of repairs.

- Ensures Safety: Maintaining proper water chemistry prevents boiler explosions and other safety hazards caused by excessive pressure or corrosion.

4. How do you monitor and control the combustion process in a recovery or combination boiler?

- Fuel Flow Control: Adjust the flow of fuel (e.g., gas, oil) to maintain the desired combustion rate.

- Air Flow Control: Regulate the air supply to ensure proper combustion and minimize emissions.

- Flue Gas Analysis: Monitor flue gases to assess combustion efficiency and make adjustments as needed.

- Oxygen Control: Maintain optimal oxygen levels in the combustion chamber to prevent incomplete combustion or excessive emissions.

- Burner Management: Operate and maintain burners to ensure proper flame stability and efficiency.

5. What are the safety hazards associated with operating a boiler, and how do you mitigate them?

- Pressure Vessels: Inspect boilers regularly for signs of corrosion, cracks, or other defects.

- Fuel Hazards: Handle and store fuel safely to prevent leaks, spills, or explosions.

- Electrical Hazards: Inspect electrical components regularly and follow proper lockout/tagout procedures.

- High Temperature and Pressure: Wear appropriate protective gear and maintain safe operating distances.

- Toxic Gases: Monitor for flue gases and other hazardous emissions, and take precautions to protect against exposure.

6. Describe the steps involved in starting up a recovery boiler.

- Pre-Startup Checks: Verify that the boiler is in good condition, fuel and water supplies are adequate, and safety systems are operational.

- Fuel Ignition: Light the burners and adjust fuel flow to establish a stable flame.

- Boiler Pressurization: Gradually increase boiler pressure by feeding water and maintaining proper steam flow.

- Temperature Control: Monitor boiler temperature and adjust fuel flow or air flow as needed to reach desired operating temperature.

- Synchronization: Synchronize the boiler with other system components, such as turbines or process lines.

7. How do you handle a boiler shutdown, including the proper procedures for depressurization and cooling?

- Gradual Shutdown: Reduce fuel flow and boiler pressure gradually to prevent thermal shock.

- Depressurization: Open drain valves slowly to release boiler pressure safely.

- Circulation Maintenance: Continue circulating water through the boiler to prevent overheating.

- Cooling: Allow the boiler to cool naturally or use controlled cooling methods, such as spraying water on the boiler shell.

- Lockout/Tagout: Lock and tag out all energy sources to prevent unauthorized access or operation.

8. What are the key performance indicators (KPIs) used to evaluate the efficiency of a boiler system?

- Steam Production Rate: Measures the amount of steam generated per unit of time.

- Boiler Efficiency: Calculates the ratio of heat input to heat output, indicating how efficiently the boiler converts fuel into steam.

- Fuel Consumption: Tracks the amount of fuel consumed to generate steam.

- Excess Air: Monitors the amount of air present in the flue gases, which affects combustion efficiency and emissions.

- Flue Gas Temperature: Measures the temperature of gases leaving the boiler, indicating heat transfer efficiency.

9. Describe the preventive maintenance tasks you regularly perform on boiler systems.

- Visual Inspections: Examine boilers for leaks, corrosion, or other visible defects.

- Equipment Cleaning: Clean boilers, burners, and other components to remove deposits and improve efficiency.

- Water Treatment Monitoring: Test and adjust boiler water chemistry to prevent scale formation and corrosion.

- Calibration and Testing: Calibrate and test safety devices, such as pressure gauges and relief valves.

- Record Keeping: Maintain accurate records of all maintenance activities for tracking and compliance purposes.

10. How do you stay updated on the latest technologies and best practices in boiler operations?

- Attend Industry Conferences: Participate in industry events and conferences to learn about new technologies and trends.

- Read Technical Journals and Publications: Stay abreast of industry publications and journals to access the latest research and advancements.

- Participate in Training and Certification Programs: Undergo training and certification programs to enhance knowledge and skills.

- Network with Other Operators: Collaborate with other boiler operators to share experiences and learn from their expertise.

- Seek Guidance from Experts: Consult with boiler manufacturers, engineers, or other experts for advice and support.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for B-Operator (Recovery and Combination Boiler Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the B-Operator (Recovery and Combination Boiler Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a B-Operator (Recovery and Combination Boiler Operator), you will be entrusted with the following key responsibilities:

1. Monitor and Control Boiler Operations

Your primary duty revolves around diligently monitoring and controlling the operations of recovery and combination boilers to ensure efficient energy production.

- Assiduously observe and adjust boiler settings and variables such as pressure, temperature, fuel flow, and water levels, maintaining optimal operating conditions.

- Scrutinize instrument readings and gauge performance indicators to preempt and promptly address any potential issues or deviations from established parameters.

2. Ensure Boiler Efficiency and Safety

You are tasked with optimizing boiler efficiency and upholding the highest standards of safety.

- Employ combustion control techniques and implement fuel optimization strategies to maximize boiler efficiency and minimize energy consumption.

- Collaborate with maintenance personnel to conduct regular inspections, preventive maintenance, and troubleshooting to ensure the reliable and safe functioning of boilers.

- Adhere strictly to established safety regulations and protocols, promptly reporting any anomalies or hazardous conditions to designated personnel.

3. Optimize Chemical Treatment

Your expertise extends to optimizing chemical treatment programs to prevent corrosion, scaling, and other detrimental effects within the boiler system.

- Monitor boiler water chemistry, conduct regular testing, and adjust chemical treatment dosages as needed to maintain ideal conditions.

- Stay abreast of industry best practices and advancements in chemical treatment technologies, incorporating innovative solutions to enhance boiler performance and longevity.

4. Coordinate with Other Departments

Effective coordination and communication with other departments are vital to your success.

- Collaborate with maintenance teams to schedule and execute maintenance activities, ensuring minimal disruption to boiler operations.

- Work closely with process engineers to optimize boiler performance and align with plant production goals.

- Communicate effectively with supervisors, operators, and other stakeholders, fostering a cohesive work environment and ensuring smooth operations.

Interview Tips

To prepare for your interview and increase your chances of success, consider the following tips:

1. Research the Company and Position

Demonstrate your genuine interest and dedication by thoroughly researching the company and the B-Operator role. Understand the company’s mission, values, and industry standing. Familiarize yourself with the specific requirements and responsibilities of the position.

- Visit the company’s website and LinkedIn page to gather information about their operations, culture, and current projects.

- Review industry publications and articles to stay informed about the latest trends and technologies relevant to boiler operations.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency and hands-on experience in boiler operations. Quantify your accomplishments and provide specific examples that showcase your ability to efficiently manage and optimize boiler systems.

- “In my previous role, I successfully implemented a new combustion control strategy that resulted in a 15% reduction in fuel consumption.”

- “I possess a proven track record of maintaining boiler efficiency above 95% consistently, minimizing energy wastage and operating costs.”

3. Showcase Safety Consciousness

Boiler operations demand an unwavering commitment to safety. Highlight your adherence to safety protocols, your ability to identify and mitigate risks, and your meticulous attention to detail when it comes to safety procedures.

- “I am a strong advocate for safety and have always prioritized the well-being of my colleagues and the integrity of the equipment I operate.”

- “I have received comprehensive training in boiler safety best practices and am certified in various safety protocols, including confined space entry and hazardous materials handling.”

4. Prepare for Technical Questions

Anticipate technical questions related to boiler operations, combustion principles, chemical treatment, and troubleshooting. Brush up on your knowledge of these topics and prepare concise answers that demonstrate your technical competence.

- Practice explaining the combustion process and the factors that influence boiler efficiency.

- Review common boiler problems and the appropriate troubleshooting steps.

5. Be Enthusiastic and Confident

Convey your enthusiasm for the role and your confidence in your abilities. Highlight your eagerness to contribute to the team and your drive to excel in this challenging and rewarding field.

- “I am passionate about optimizing boiler performance and ensuring the safe and efficient operation of energy systems.”

- “I am confident that my skills and experience make me an ideal candidate for this role, and I am eager to contribute to the success of your organization.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the B-Operator (Recovery and Combination Boiler Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!