Feeling lost in a sea of interview questions? Landed that dream interview for Back Digger Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Back Digger Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

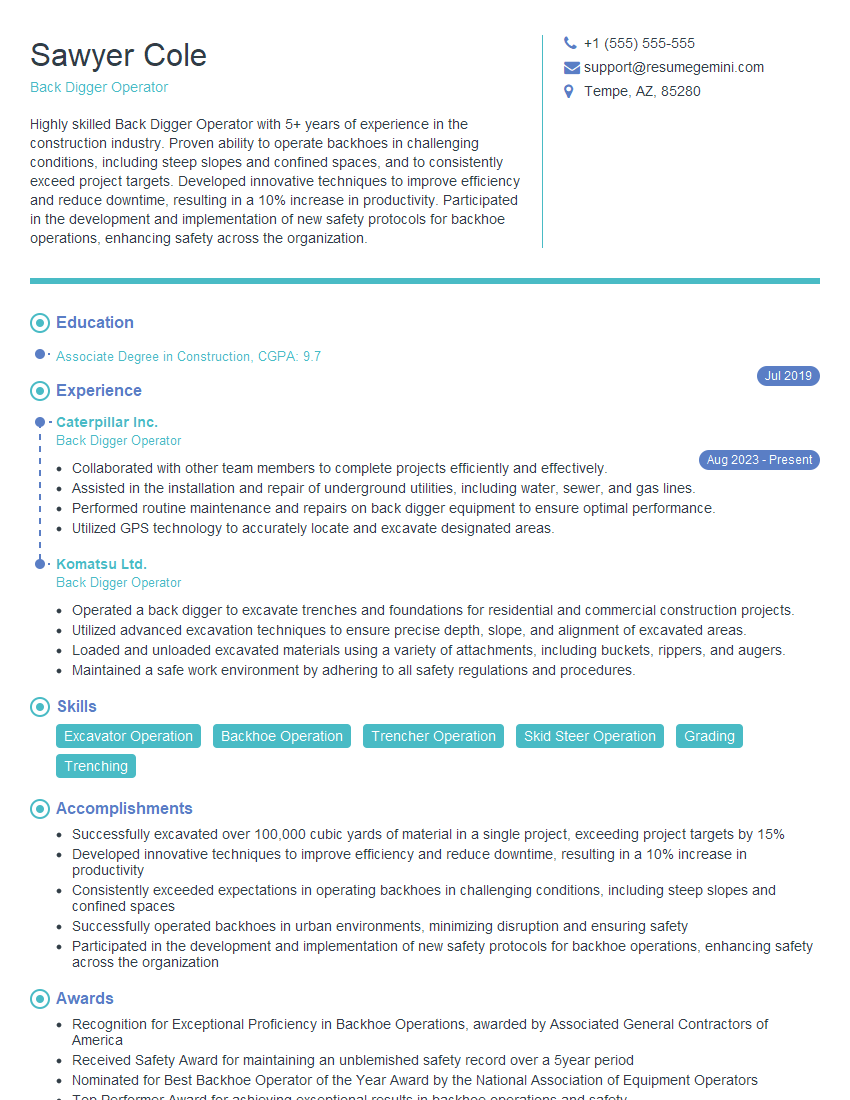

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Back Digger Operator

1. How do you determine the depth and stability of the soil before digging?

To determine the depth and stability of the soil before digging, I consider the following factors:

- Visual Inspection: I examine the soil surface for signs of erosion, cracks, or soft spots.

- Hand Testing: I insert a probe or rod into the soil to feel its consistency and resistance.

- Soil Density Test: I use a penetrometer to measure the soil’s density and compaction.

- Historical Data: I consult soil maps, reports, or previous excavation data to gain insights into the soil conditions.

- Experience: I rely on my experience in dealing with different soil types to make informed judgments.

2. What are the safety protocols you follow when operating a back digger?

Personal Protective Equipment

- Wear a hard hat, safety goggles, and gloves.

- Ensure high-visibility clothing for improved visibility.

Machine Inspection and Operation

- Conduct a thorough pre-operation inspection of the machine.

- Maintain a safe distance from overhead power lines.

- Operate the back digger within its designated work area.

- Signal clearly to other workers when operating the machine.

Emergency Procedures

- Know the location of the emergency stop button.

- Be aware of evacuation routes and procedures.

3. How do you troubleshoot common back digger problems, such as hydraulic leaks or engine issues?

To troubleshoot common back digger problems, I follow these steps:

- Hydraulic Leaks:

- Inspect hoses, fittings, and seals for cracks or damage.

- Check the hydraulic fluid level and condition.

- Use a leak detection dye to identify the precise source of the leak.

- Engine Issues:

- Check fuel levels and filters.

- Inspect the spark plugs or glow plugs.

- Diagnose engine codes using diagnostic equipment.

4. How do you calculate the weight and volume of the material you have excavated?

To calculate the weight and volume of the excavated material, I use the following methods:

- Weight Calculation:

- Estimate the material’s density based on its type and moisture content.

- Multiply the volume of the excavated material by its density to determine the weight.

- Volume Calculation:

- Measure the dimensions of the excavated area (length, width, and depth).

- Calculate the volume using the formula for the shape of the excavated area (e.g., prism, cylinder).

5. What techniques do you use to ensure precision digging and avoid over-excavation?

To achieve precision digging and prevent over-excavation, I employ the following techniques:

- Laser Leveling: Use a laser level to establish accurate excavation depths and slopes.

- Grade Stakes and String Lines: Set up grade stakes and string lines to guide the back digger’s bucket.

- Precision Controls: Utilize the back digger’s precision controls for smooth and controlled movements.

- Regular Monitoring: Continuously monitor the excavation progress and adjust the digging depth as needed.

- Experience and Skill: Rely on my experience and skill to anticipate soil conditions and make adjustments accordingly.

6. How do you handle working in confined spaces when operating a back digger?

When working in confined spaces, I prioritize safety by implementing the following measures:

- Risk Assessment: Conduct a thorough risk assessment to identify potential hazards and implement control measures.

- Ventilation: Ensure adequate ventilation to maintain air quality and prevent the buildup of harmful gases.

- Excavation Support: Install shoring or bracing systems to prevent cave-ins and maintain the stability of the work area.

- Communication: Establish clear communication channels with other workers and supervisors to coordinate movements and ensure safety.

- Emergency Plan: Develop and implement an emergency plan outlining evacuation procedures and rescue protocols.

7. What maintenance tasks do you regularly perform on a back digger to ensure optimal performance?

To maintain optimal performance and prevent breakdowns, I regularly perform the following maintenance tasks:

- Daily Inspections: Check fluid levels, tires, filters, and belts for wear or damage.

- Weekly Greasing: Lubricate all moving parts, including pins, bushings, and bearings.

- Monthly Servicing: Replace filters, check hydraulic hoses, and inspect the engine.

- Quarterly Inspections: Conduct a thorough inspection of the entire machine, including electrical systems and safety features.

- Annual Maintenance: Perform major overhauls, including engine servicing, hydraulic system flushing, and bucket tooth replacement.

8. How do you plan and execute complex excavation projects involving multiple machinery and workers?

To effectively plan and execute complex excavation projects, I follow these steps:

- Site Assessment: Conduct a thorough site assessment, considering soil conditions, terrain, and potential hazards.

- Project Planning: Develop a detailed excavation plan outlining the sequence of operations, equipment requirements, and safety protocols.

- Equipment Coordination: Ensure proper coordination and communication between multiple machines and operators.

- Safety Management: Implement a comprehensive safety plan, including hazard identification, risk assessment, and emergency procedures.

- Progress Monitoring: Regularly monitor project progress, make necessary adjustments, and keep stakeholders informed.

9. How do you avoid damaging underground utilities and infrastructure during excavation?

To prevent damage to underground utilities and infrastructure, I take the following precautions:

- Utility Mapping: Obtain and review utility maps before commencing excavation.

- Hand Digging: Use hand tools to carefully expose underground utilities and infrastructure.

- Protective Measures: Install protective barriers or padding around sensitive utilities.

- Communication: Coordinate with utility companies to avoid conflicts and ensure their involvement if necessary.

- Visual Inspection: Continuously inspect the excavation area for signs of buried utilities or infrastructure.

10. How do you stay up-to-date on the latest back digger technology and industry best practices?

To remain current with the latest technology and best practices, I engage in the following activities:

- Trade Shows and Conferences: Attend industry events to learn about new equipment and innovations.

- Technical Publications: Subscribe to trade magazines and online resources for updates on industry trends.

- Manufacturer Training: Participate in training programs offered by back digger manufacturers.

- Online Learning: Utilize online platforms and resources to expand my knowledge.

- Networking: Connect with other professionals in the field to exchange ideas and share experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Back Digger Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Back Digger Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Back Digger Operators are responsible for operating and maintaining back diggers, heavy machinery used in excavation and construction projects. They play a crucial role in site preparation, trench digging, and material handling. The key job responsibilities of a Back Digger Operator include:

1. Equipment Operation

Operate back diggers safely and efficiently, following established operating procedures.

- Control the machine’s hydraulics, boom, and bucket to perform digging, trenching, and material handling tasks.

- Monitor equipment performance and make adjustments as needed to optimize productivity.

2. Site Preparation

Prepare construction sites by clearing vegetation, leveling ground, and excavating foundations.

- Use the back digger to remove topsoil, rocks, and other debris from the site.

- Level the ground to create a stable base for construction.

- Excavate trenches for underground utilities, drainage systems, and other infrastructure.

3. Material Handling

Load, unload, and transport materials using the back digger.

- Use the bucket to scoop up and move soil, gravel, sand, and other materials.

- Load materials into dump trucks, conveyors, or other equipment for transportation.

- Unload materials at designated locations and ensure proper placement.

4. Maintenance and Inspections

Perform routine maintenance and inspections on the back digger.

- Check fluid levels, filters, and other components for proper operation.

- Lubricate moving parts to reduce wear and tear.

- Inspect the machine for any damage or defects and report any issues promptly.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Back Digger Operator position:

1. Research the Company and Position

Take the time to research the company you are applying to, including their history, values, and current projects. This will demonstrate your interest in the position and show the interviewer that you have put effort into the interview process.

- Visit the company’s website and social media pages to learn about their operations and industry expertise.

- Read industry news and articles to stay informed about the latest trends and technologies in the construction sector.

2. Practice Common Interview Questions

Anticipate the common interview questions you may encounter and prepare your answers in advance. This will help you articulate your skills and experience effectively.

- Tell me about your experience operating back diggers.

- Describe a challenging excavation project you have worked on.

- How do you ensure safety when working with heavy machinery?

- What are your strengths and weaknesses as a Back Digger Operator?

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to provide concrete evidence of your contributions.

- Use specific examples to demonstrate your proficiency in operating back diggers.

- Mention any certifications or training programs you have completed.

- Discuss your experience in site preparation, material handling, and equipment maintenance.

4. Demonstrate Your Safety Consciousness

Safety is paramount in construction, and interviewers will be eager to know your approach to workplace safety. Highlight your commitment to following safety protocols and maintaining a safe work environment.

- Explain your understanding of industry safety regulations.

- Describe your experience in conducting pre-operation inspections and adhering to established safety procedures.

- Share an example of how you identified and mitigated a potential safety hazard on a job site.

5. Prepare Questions for the Interviewer

At the end of the interview, interviewers often ask candidates if they have any questions. This is an excellent opportunity to show your engagement and interest in the position.

- Ask about the company’s upcoming projects and how the position fits into their long-term plans.

- Inquire about the training and professional development opportunities available.

- Ask about the company’s safety policies and procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Back Digger Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Back Digger Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.