Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Back Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

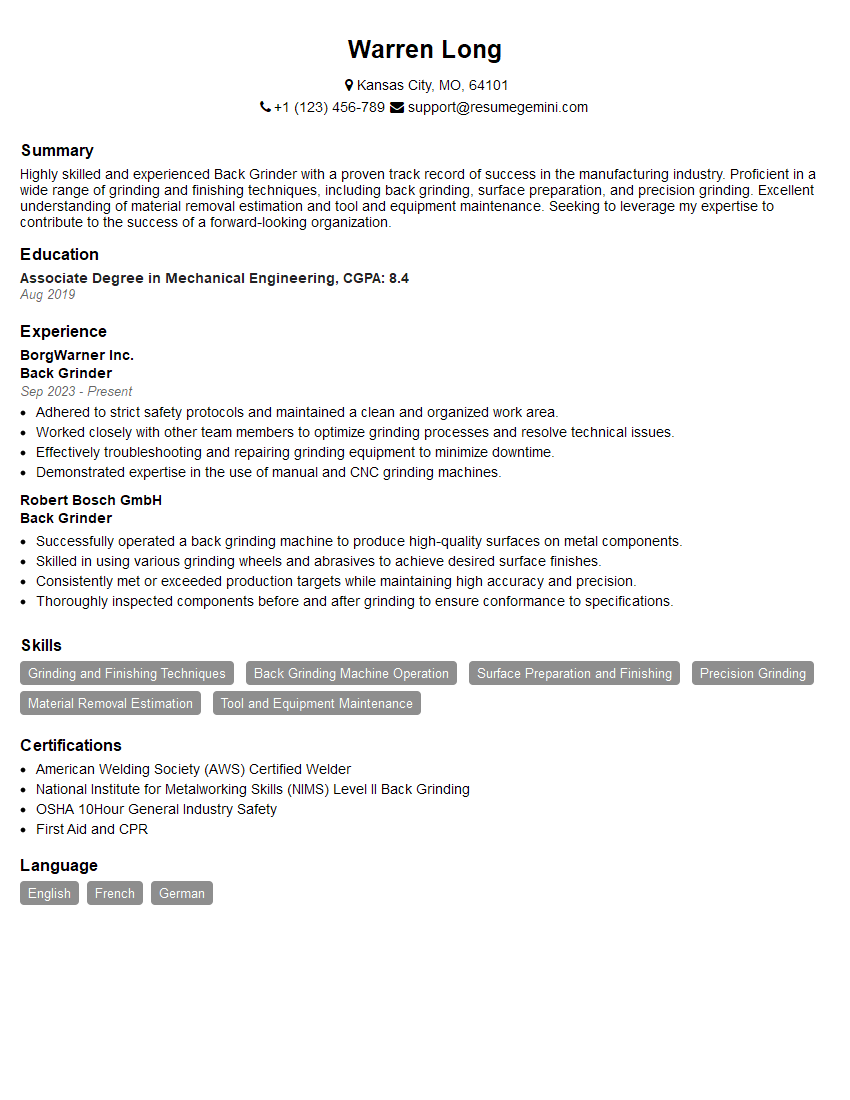

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Back Grinder

1. What are the different types of back grinding machines?

There are two main types of back grinding machines: vertical and horizontal. Vertical back grinding machines are used for grinding the backs of large, flat workpieces, while horizontal back grinding machines are used for grinding the backs of smaller, more complex workpieces.

2. What are the advantages and disadvantages of vertical and horizontal back grinding machines?

Vertical back grinding machines are more efficient for grinding large, flat workpieces because they allow for a faster feed rate and can remove more material in a single pass. However, vertical back grinding machines are also more expensive and complex to operate than horizontal back grinding machines.

Horizontal back grinding machines are more versatile and can be used to grind a wider variety of workpieces. However, horizontal back grinding machines are slower and less efficient than vertical back grinding machines.

3. What are the key factors to consider when choosing a back grinding machine?

The key factors to consider when choosing a back grinding machine include the size and shape of the workpieces to be ground, the required accuracy and finish, the production volume, and the budget.

4. How do you set up a back grinding machine?

To set up a back grinding machine, the following steps are typically followed:

- The workpiece is clamped to the worktable.

- The grinding wheel is selected and mounted to the spindle.

- The grinding wheel is dressed to the desired shape and size.

- The machine is set to the desired grinding parameters, such as the feed rate, grinding speed, and depth of cut.

5. How do you operate a back grinding machine?

To operate a back grinding machine, the following steps are typically followed:

- The machine is started and the workpiece is brought into contact with the grinding wheel.

- The workpiece is traversed across the grinding wheel at a controlled feed rate.

- The grinding wheel is used to remove material from the workpiece until the desired thickness or finish is achieved.

- The workpiece is removed from the machine and inspected.

6. How do you maintain a back grinding machine?

To maintain a back grinding machine, the following tasks should be performed regularly:

- The machine should be cleaned and lubricated.

- The grinding wheel should be inspected and dressed as needed.

- The machine should be calibrated regularly to ensure accurate grinding.

7. What are the common problems that can occur with back grinding machines?

The common problems that can occur with back grinding machines include:

- Vibration

- Chatter

- Burnishing

- Loading

- Glazing

8. How do you troubleshoot problems with back grinding machines?

To troubleshoot problems with back grinding machines, the following steps are typically followed:

- Identify the symptoms of the problem.

- Check the machine for any obvious problems, such as loose wires or worn parts.

- Refer to the machine’s manual for troubleshooting tips.

- Contact the machine manufacturer for assistance.

9. What are the safety precautions that should be taken when operating a back grinding machine?

The following safety precautions should be taken when operating a back grinding machine:

- Wear appropriate safety gear, such as safety glasses, gloves, and a dust mask.

- Keep the work area clean and clear of debris.

- Ensure that the machine is properly grounded.

- Never operate the machine if it is damaged or malfunctioning.

10. What are the career opportunities for back grinders?

Back grinders can find work in a variety of industries, including manufacturing, automotive, and aerospace. The career opportunities for back grinders include:

- Back grinder operator

- Back grinder setup technician

- Back grinder maintenance technician

- Back grinder engineer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Back Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Back Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Back Grinders are responsible for removing excess material from the backs of glass sheets using a grinding machine. They ensure that the glass sheets meet the required specifications and are ready for further processing.

1. Grinding and Polishing

Operate grinding machines to remove excess material from the backs of glass sheets.

- Set up and adjust grinding machines according to specifications.

- Load glass sheets onto the grinding machine and secure them in place.

- Start the grinding process and monitor the progress.

- Polish the backs of the glass sheets to achieve the desired finish.

2. Inspecting Products

Inspect the finished glass sheets to ensure they meet the required specifications.

- Check for defects such as scratches, chips, or bubbles.

- Measure the thickness and dimensions of the glass sheets.

- Ensure that the glass sheets are free from dirt and debris.

3. Machine Maintenance

Perform basic maintenance on grinding machines.

- Clean and lubricate the grinding machines regularly.

- Replace worn or damaged parts as needed.

- Report any major maintenance issues to the supervisor.

4. Safety Measures

Follow all safety procedures and wear appropriate personal protective equipment (PPE).

- Wear safety glasses, gloves, and earplugs.

- Follow proper lifting techniques when handling heavy glass sheets.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

To ace the interview for a Back Grinder position, candidates should prepare thoroughly by understanding the key job responsibilities and practicing their answers to common interview questions.

1. Research the Company and Position

Take the time to research the company and the specific Back Grinder position you are applying for. Learn about the company’s culture, values, and products or services. This will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and read about their mission, history, and team.

- Check out the company’s social media pages to get a sense of their culture and values.

- If possible, reach out to current or former employees of the company to learn more about the work environment and the Back Grinder position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

- Start by brainstorming all of the possible questions that you could be asked.

- Write out your answers in advance and practice saying them out loud.

- Ask a friend or family member to conduct a mock interview with you.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged, interested, and prepared. It also gives you an opportunity to learn more about the company and the position.

- Come up with a few questions that you would like to ask the interviewer about the company, the position, or the team.

- Examples of good questions include “What are the company’s growth plans for the next year?” or “What are the biggest challenges facing the Back Grinder team right now?”

4. Be Yourself and Let Your Personality Shine Through

It is important to be yourself and let your personality shine through in the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident, enthusiastic, and genuine, and you’ll be sure to make a great impression.

- Be yourself and don’t try to be someone you’re not.

- Be confident and enthusiastic, but not overbearing.

- Be genuine and don’t try to sugarcoat your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Back Grinder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!