Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Back Joiner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Back Joiner so you can tailor your answers to impress potential employers.

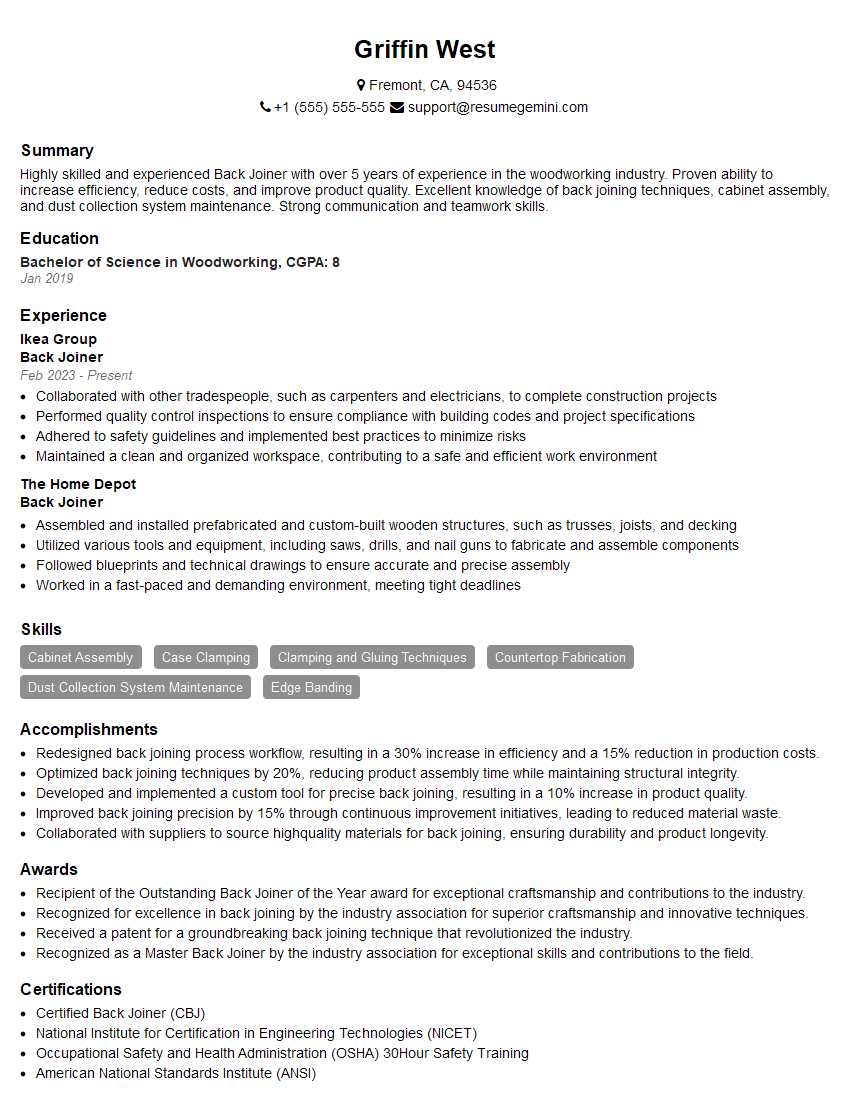

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Back Joiner

1. What are the different types of door frames?

There are several types of door frames, including:

- Solid Wood Frames: These frames are made from a single piece of wood and are known for their durability and strength.

- Timber Frames: Made from smaller pieces of wood that are joined together, these frames are strong and affordable.

- Metal Frames: Durable and fire-resistant, these frames are often used in commercial and industrial settings.

- Composite Frames: Combining wood and synthetic materials, these frames are moisture-resistant and offer a balance of strength and affordability.

2. What is the process of joinery for a window frame?

Cutting and Preparation

- Measure and cut the frame components to the desired size.

- Prepare the joints by cutting mortises, tenons, or other joinery methods.

Assembly

- Assemble the frame components using glue, nails, or screws.

- Secure the joints with clamps or other fixtures until the glue dries or the fasteners set.

Fitting

- Fine-tune the fit of the frame in the window opening.

- Adjust the hinges and other hardware to ensure proper operation.

3. How do you ensure that a door frame is plumb and level?

To ensure that a door frame is plumb and level:

- Use a spirit level to check the vertical and horizontal alignment of the frame.

- Adjust the shims behind the frame as needed to level it.

- Use a plumb bob or laser level to check the vertical alignment of the frame.

- Make further adjustments to the shims or the frame itself until it is both plumb and level.

4. What are the factors to consider when selecting the right hinges for a door?

When selecting hinges for a door, the following factors should be considered:

- Door Weight and Size: Choose hinges that can support the weight of the door.

- Door Material: Select hinges that are compatible with the material of the door.

- Swing Direction: Determine the direction the door will swing and choose hinges accordingly.

- Style: Consider the aesthetic appeal of the hinges and select ones that complement the door design.

- Security: Opt for hinges that provide adequate security measures against forced entry.

5. How do you install a window sill?

- Measure and cut the window sill to the desired size.

- Apply a layer of caulk or sealant to the bottom of the window frame.

- Place the window sill on the frame and press it firmly into place.

- Secure the sill with nails or screws.

- Apply caulk around the edges of the sill to seal it.

6. What types of joinery techniques are used in cabinetry?

Mortise and Tenon

A mortise is a hole cut into one piece of wood, while the tenon is a protruding tongue cut into another piece. These pieces are joined together for a strong and durable connection.

Dovetail

Dovetails are interlocking joints where the shape resembles a dove’s tail. They provide a very strong and precise joint.

Dado

A dado is a groove cut into the edge of one piece of wood to receive the edge of another piece, creating a shelf or other support.

7. How do you cut and join mitered corners?

- Measure and mark the 45-degree angles on both pieces of wood where they will meet.

- Use a miter saw to cut both pieces at the marked angles.

- Apply wood glue to the mitered edges.

- Clamp the pieces together and secure them with nails or screws.

8. What are the different types of wood finishes?

Paint

Paint is a liquid coating that provides both color and protection to wood.

Stain

Stain is a transparent or semi-transparent liquid that enhances the natural grain of the wood.

Varnish

Varnish is a clear or tinted liquid that provides a protective layer, giving wood a glossy or matte finish.

Shellac

Shellac is a natural resin that provides a durable and water-resistant finish.

Oil

Oil penetrates the wood fibers, providing moisture protection and a natural look.

9. How do you repair a cracked or damaged piece of furniture?

Assessment

Inspect the damage to determine its extent and the best course of repair.

Disassembly

If necessary, disassemble the furniture to gain access to the damaged area.

Repair

Use appropriate techniques such as gluing, clamping, filling, or replacing damaged parts.

Reassembly

Once the repair is complete, reassemble the furniture and check its functionality.

Finishing

Apply a finish or touch up the repair to match the surrounding area.

10. How do you ensure that a piece of furniture is square and level?

- Use a square to check the angles between the sides of the furniture.

- Use a level to check the horizontal and vertical alignment of the furniture.

- Make adjustments to the joints or the furniture itself until it is both square and level.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Back Joiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Back Joiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Fabricate and Erect

Fabricate and erect back joinery for furniture, fixtures, and casework.

- Interpret plans and specifications to determine work requirements.

- Select and prepare materials, including wood, veneers, and hardware.

- Operate machinery and equipment, such as jointers, planers, and saws, to fabricate components.

- Assemble and fit components using hand tools, power tools, and adhesives.

- Install back joinery in furniture, fixtures, and casework.

2. Maintain Quality and Inspect

Maintain quality standards and inspect back joinery for accuracy and precision.

- Inspect materials and components for defects and ensure compliance with specifications.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Perform quality checks throughout the fabrication and installation process.

3. Supervise and Train

Supervise and train apprentices and other back joiners.

- Provide guidance and instruction to less experienced workers.

- Monitor progress and provide feedback on performance.

- Identify training needs and develop training programs.

4. Safety and Compliance

Maintain a safe and compliant work environment.

- Follow safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

- Comply with all applicable laws and regulations.

Interview Tips

1. Research and Practice

Research the company, the industry, and the specific role to demonstrate your interest and understanding.

- Review the job description thoroughly and identify key requirements.

- Practice answering common back joiner interview questions.

- Prepare examples of your work that highlight your skills and experience.

2. Showcase Your Skills and Experience

Quantify your accomplishments and provide specific examples to showcase your skills and experience.

- Highlight your experience in fabricating and installing back joinery in furniture, fixtures, and casework.

- Discuss your quality control and inspection experience.

- Provide examples of your supervisory and training abilities.

3. Emphasize Your Commitment to Safety

Emphasize your commitment to maintaining a safe and compliant work environment.

- Discuss your knowledge of safety protocols and regulations.

- Provide examples of your efforts to promote safety in your previous roles.

4. Questions for Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role.

- Ask about the company’s culture and values.

- Inquire about opportunities for professional development.

- Ask about the specific challenges and rewards of the role.

5. Professionalism and Preparation

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview.

- Prepare questions to ask the interviewer.

- Bring a portfolio or samples of your work, if appropriate.

- Follow up with a thank-you note after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Back Joiner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.