Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Back-Strip Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Back-Strip Machine Operator so you can tailor your answers to impress potential employers.

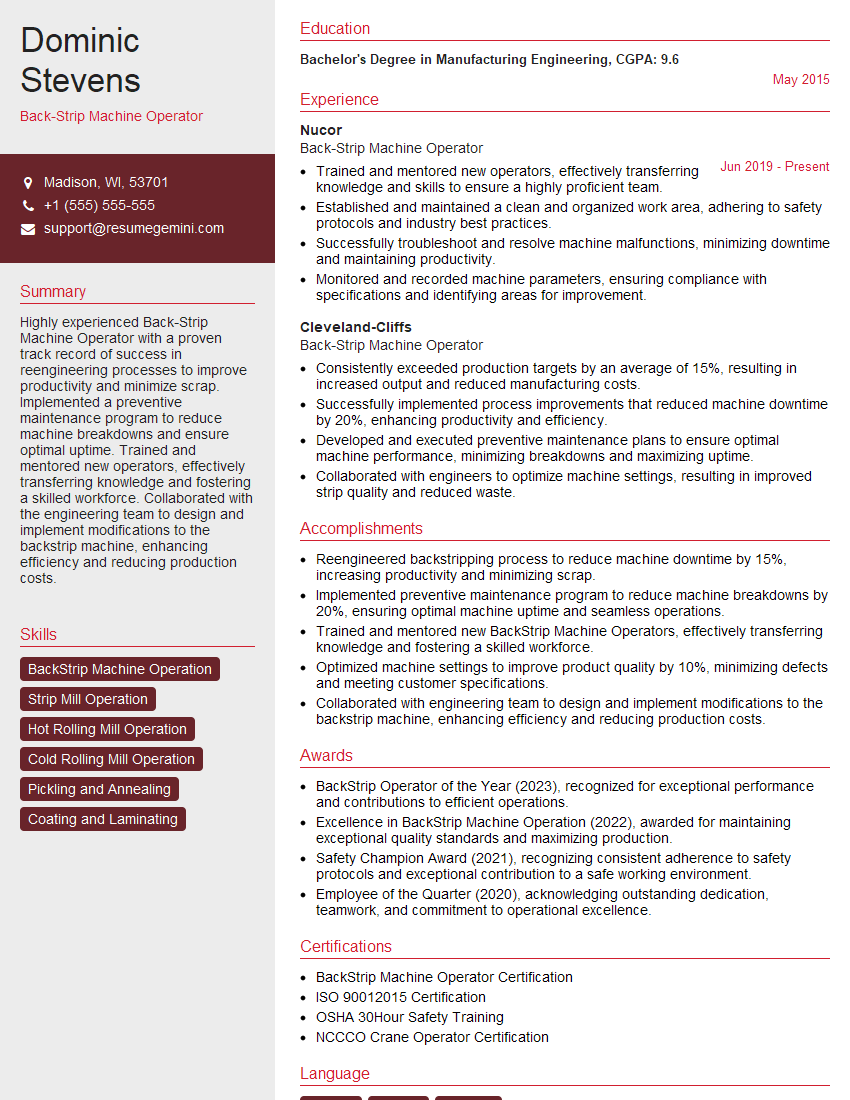

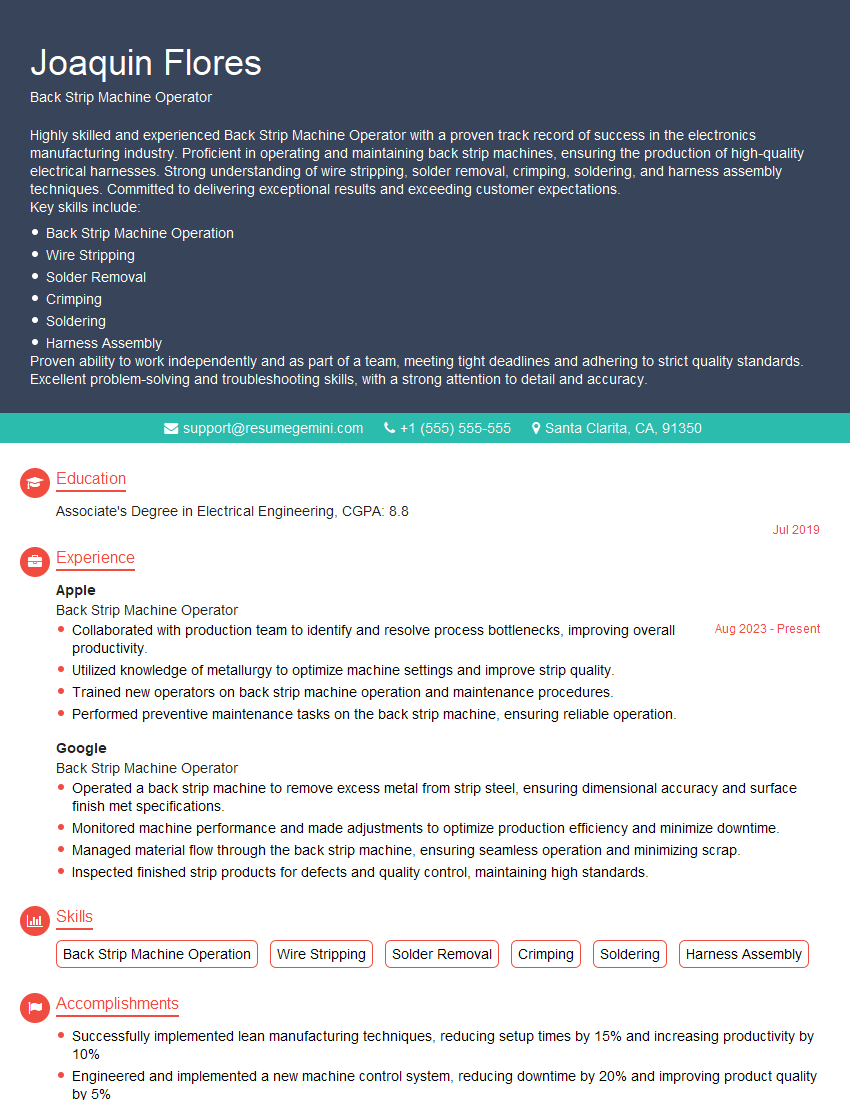

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Back-Strip Machine Operator

1. What are the key responsibilities of a Back-Strip Machine Operator?

As a Back-Strip Machine Operator, my responsibilities encompass a range of tasks essential for the smooth functioning of the production line, including:

- Monitoring and operating the back-strip machine to remove excess material from the edges of printed circuit boards (PCBs).

- Performing quality checks on the PCBs to ensure they meet the required specifications and industry standards.

- Maintaining and calibrating the back-strip machine to ensure optimal performance and precision.

- Adhering to safety protocols and following established operating procedures to ensure a safe work environment.

- Collaborating with team members to troubleshoot any issues that may arise during the production process.

2. Describe the different types of back-strip machines and their applications

CNC Back-Strip Machines

- Computer-controlled machines with high precision and repeatability.

- Used for complex PCB designs and high-volume production.

Semi-Automatic Back-Strip Machines

- Operator-controlled machines with manual loading and unloading.

- Suitable for medium-volume production and less complex PCB designs.

Manual Back-Strip Machines

- Entirely manual operation, requiring skilled operators.

- Typically used for low-volume production or prototyping.

3. What are the critical quality parameters to monitor during the back-stripping process?

- Edge Clearance: Ensuring the correct amount of material is removed from the edges of the PCB to prevent shorts or open circuits.

- Solder Mask Removal: Verifying that the solder mask is completely removed from the exposed copper pads to ensure proper solderability.

- Surface Finish: Inspecting the surface of the PCB for any nicks, scratches, or burrs that could affect the performance or reliability of the board.

- Dimensional Accuracy: Measuring the width and thickness of the back-stripped area to ensure it meets the design specifications.

- Cleanliness: Checking for any debris or contaminants that could interfere with the subsequent manufacturing processes or affect the board’s performance.

4. Explain the importance of proper blade selection and maintenance for back-stripping operations.

Selecting the correct blade type and maintaining it properly are crucial for efficient and high-quality back-stripping:

- Blade Type: Choosing the right blade material (e.g., carbide, diamond) and geometry (e.g., shape, angle) ensures clean cuts and minimizes damage to the PCB.

- Blade Maintenance: Regular sharpening and cleaning of the blade are essential to maintain its sharpness and prevent tearing or delamination of the PCB material.

- Blade Inspection: Periodically inspecting the blade for wear, damage, or dullness helps identify potential issues early on and prevents them from affecting production quality.

5. Describe the steps involved in troubleshooting common back-strip machine issues.

- Identify the Problem: Observe the machine’s behavior, check for error messages, and inspect the PCBs for defects.

- Check the Blade: Ensure the blade is sharp, clean, and properly installed.

- Calibrate the Machine: Verify the machine’s settings (e.g., speed, pressure) and adjust as necessary.

- Inspect the Material: Check the thickness and composition of the PCB material to ensure it is compatible with the machine’s capabilities.

- Consult the Manual: Refer to the machine’s user manual for specific troubleshooting guidance.

6. Explain how you ensure the safety of yourself and others while operating a back-strip machine.

- Wear Appropriate PPE: Utilize safety glasses, gloves, and hearing protection to minimize the risk of injury.

- Follow Safety Procedures: Adhere to established safety protocols, including lockout/tagout procedures and proper machine handling techniques.

- Maintain a Clean and Organized Workspace: Keep the work area free of clutter and ensure proper ventilation to prevent tripping hazards or exposure to harmful fumes.

- Be Aware of Surrounding Equipment: Pay attention to the location of other machinery and avoid operating the back-strip machine in close proximity to potential hazards.

- Report any Issues Promptly: Immediately notify supervisors or maintenance personnel of any safety concerns or equipment malfunctions.

7. Describe the importance of maintaining accurate records and documentation in the back-strip process.

- Quality Control: Records provide traceability and allow for the identification of any defects or issues that may arise during production.

- Process Optimization: Documentation enables the analysis of production data to identify areas for improvement and optimize the back-stripping process.

- Compliance: Accurate records are essential for meeting industry standards and regulatory requirements related to PCB manufacturing.

- Customer Satisfaction: Well-maintained records provide evidence of the quality of the back-stripping process and help build customer confidence.

8. Explain how you stay up-to-date with the latest back-strip machine technologies and best practices.

- Attend Industry Events: Participate in conferences, workshops, and trade shows to learn about new technologies and advancements.

- Read Technical Publications: Stay informed by reading industry journals, whitepapers, and technical articles.

- Network with Peers: Connect with other Back-Strip Machine Operators and share knowledge and experiences.

- Participate in Training Programs: Seek opportunities for training on the latest equipment and techniques.

- Utilize Online Resources: Explore online forums, webinars, and manufacturer websites for information and support.

9. Describe your experience in working with different types of PCB materials.

Throughout my career, I have gained proficiency in handling a wide range of PCB materials, including:

- FR-4: A commonly used material known for its strength, durability, and low cost.

- CEM-1: A high-performance material with excellent electrical properties and thermal stability.

- Aluminum-Based PCBs: Lightweight and thermally conductive materials suitable for high-power applications.

- Flexible PCBs: Thin and bendable materials used in electronic devices such as smartphones and wearables.

- Specialty Materials: Experience with specialized materials such as polyimide and ceramic for demanding applications.

10. Explain how you handle the production of PCBs with complex back-strip requirements.

When dealing with PCBs that have intricate back-strip requirements, I approach the process with the following strategies:

- Careful Planning: Thoroughly reviewing the design specifications and conducting trial runs to determine the optimal settings and blade selection.

- Precision Setup: Meticulously calibrating the back-strip machine and ensuring the blade is aligned precisely to achieve the desired results.

- Continuous Monitoring: Paying close attention to the back-stripping process and making adjustments as needed to maintain accuracy and quality.

- Advanced Techniques: Utilizing advanced techniques such as laser back-stripping or CNC programming to achieve highly precise and complex back-strip patterns.

- Collaboration: Working closely with design engineers to understand the specific requirements and ensure the final product meets the intended functionality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Back-Strip Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Back-Strip Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Back-Strip Machine Operator is responsible for operating and maintaining a back-strip machine, which is used to remove the thin strip of material from the back of a metal plate. The key job responsibilities include:

1. Machine Operation

Operate the back-strip machine to remove the back-strip from the metal plate.

- Set up and adjust the machine according to the required specifications.

- Load and unload the metal plates onto the machine.

2. Machine Maintenance

Perform routine maintenance and repairs on the back-strip machine.

- Clean and lubricate the machine.

- Inspect the machine for any signs of wear or damage.

- Troubleshoot and resolve any problems that may occur.

3. Quality Control

Ensure that the back-strip is removed to the required specifications.

- Inspect the back-strip for any defects or irregularities.

- Adjust the machine settings as necessary to maintain the required quality standards.

4. Safety

Follow all safety procedures and regulations.

- Wear appropriate personal protective equipment.

- Keep the work area clean and organized.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

To prepare for a Back-Strip Machine Operator interview, candidates should focus on highlighting their experience and skills in operating and maintaining back-strip machines. They should also be prepared to discuss their knowledge of safety procedures and regulations. Here are some specific tips:

1. Research the Company and the Position

Before the interview, candidates should research the company and the specific position they are applying for. This will help them understand the company’s culture, values, and the specific requirements of the job.

- Visit the company’s website to learn about its products, services, and history.

- Read any news articles or press releases about the company.

- Connect with employees on LinkedIn to get insights into the company culture.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions related to their experience, skills, and qualifications. This will help them feel more confident and prepared during the interview.

- What is your experience in operating and maintaining back-strip machines?

- What are your strengths and weaknesses as a Back-Strip Machine Operator?

- How do you ensure that the back-strip is removed to the required specifications?

3. Be Prepared to Discuss Safety Procedures

Candidates should be prepared to discuss their knowledge of safety procedures and regulations related to operating back-strip machines.

- What are the most important safety procedures to follow when operating a back-strip machine?

- What should you do if you witness an unsafe condition or practice?

- How do you stay up-to-date on the latest safety regulations?

4. Highlight Your Skills and Experience

Candidates should highlight their skills and experience that are relevant to the position. This includes both technical skills and soft skills.

- Technical skills: Experience in operating and maintaining back-strip machines, knowledge of safety procedures, ability to troubleshoot and resolve problems.

- Soft skills: Communication skills, teamwork skills, problem-solving skills.

5. Be Enthusiastic and Positive

Candidates should be enthusiastic and positive during the interview. This will show the interviewer that they are interested in the position and the company.

- Smile and make eye contact with the interviewer.

- Answer questions clearly and concisely.

- Ask thoughtful questions about the position and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Back-Strip Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Back-Strip Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.