Are you gearing up for a career in Back Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Back Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

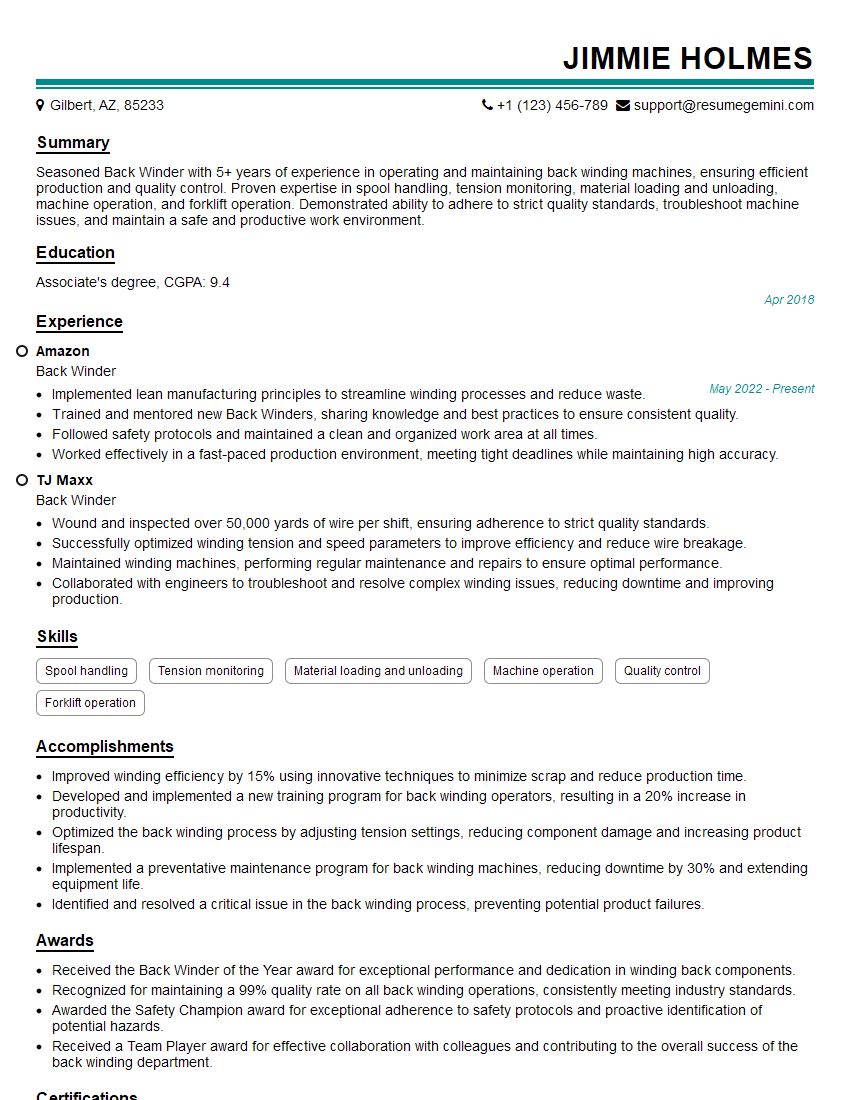

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Back Winder

1. Explain the different types of winding machines used in a back winding operation?

In a back winding operation, there are several types of winding machines used:

- Linear Winders: These machines wind wire linearly onto a bobbin, creating a cylindrical coil.

- Toroidal Winders: These machines wind wire onto a toroidal core, creating a donut-shaped coil.

- Multi-Head Winders: These machines use multiple winding heads to simultaneously wind multiple coils onto a single bobbin or core.

- CNC Winders: These machines are computer-controlled and can wind complex coils with high precision.

2. What are the critical parameters to consider when selecting the appropriate winding machine for a specific application?

When selecting a winding machine, the following critical parameters should be considered:

- Coil Geometry: The shape and size of the coil being wound.

- Wire Type and Gauge: The material, thickness, and insulation of the wire being wound.

- Winding Speed: The desired production rate.

- Precision Requirements: The tolerance levels required for the wound coil.

- Automation Capabilities: The level of automation required, such as automatic wire feeding and coil ejection.

3. Describe the process of setting up and operating a CNC winding machine?

Setting up and operating a CNC winding machine typically involves the following steps:

- Loading the wire: Threading the wire onto the winding head.

- Programming the machine: Inputting the winding parameters into the machine’s control system.

- Calibrating the machine: Verifying the machine’s accuracy and making adjustments as needed.

- Starting the winding process: Initiating the winding cycle.

- Monitoring the process: Observing the winding process and making adjustments as necessary.

- Unloading the wound coil: Removing the completed coil from the machine.

4. What are the common maintenance tasks required for winding machines, and how often should they be performed?

Regular maintenance tasks for winding machines include:

- Cleaning: Removing dust, debris, and wire clippings from the machine.

- Lubrication: Applying lubricants to moving parts.

- Belt and chain replacement: Replacing worn belts and chains.

- Calibration: Verifying the machine’s accuracy and making adjustments as needed.

- Electrical inspections: Checking electrical connections and components.

- Scheduled maintenance: Regular servicing by a qualified technician to ensure optimal performance.

5. How do you troubleshoot common winding machine problems, such as wire breaks, tension issues, and coil deformation?

Troubleshooting common winding machine problems involves the following steps:

- Identifying the problem: Determining the specific issue affecting the winding process.

- Checking the machine settings: Verifying that the winding parameters are correct.

- Inspecting the wire: Examining the wire for damage or defects.

- Adjusting the tension: Modifying the tension settings to ensure proper wire tension.

- Checking the winding head: Verifying that the winding head is operating correctly and not causing coil deformation.

- Calibrating the machine: Re-calibrating the machine to ensure accuracy.

6. How do you ensure the quality of wound coils meets customer specifications?

Ensuring the quality of wound coils involves the following practices:

- Adhering to specifications: Following the customer’s specified requirements for coil dimensions, winding patterns, and electrical properties.

- Regular inspections: Performing visual and electrical inspections of wound coils to identify any defects or non-conformities.

- Testing and measurement: Using appropriate testing equipment to verify the electrical and mechanical properties of wound coils.

- Process control: Monitoring and controlling the winding process to maintain consistent quality.

- Continuous improvement: Regularly evaluating and improving winding techniques to enhance coil quality.

7. Describe the different types of wire insulation materials used in back winding and their properties?

In back winding, various types of wire insulation materials are used, each with unique properties:

- Polyurethane (PU): Known for its flexibility, abrasion resistance, and high voltage capabilities.

- Polyethylene Terephthalate (PET): Provides excellent electrical insulation, temperature resistance, and chemical resistance.

- Polytetrafluoroethylene (PTFE): Offers exceptional temperature resistance, chemical resistance, and low friction, making it suitable for high-frequency applications.

- Polyimide (PI): Known for its high-temperature stability, radiation resistance, and excellent dielectric properties.

- Nomex: A high-temperature resistant material with good electrical insulation and flame retardancy.

8. How do you calculate the number of turns and wire length required for a specific coil design?

Calculating the number of turns and wire length requires the following steps:

- Determining the coil geometry: Calculate the inner diameter, outer diameter, and winding height.

- Choosing the wire gauge: Select the appropriate wire gauge based on current-carrying capacity and resistance requirements.

- Calculating the mean diameter: Average the inner and outer diameters to get the mean diameter.

- Calculating the number of turns: Divide the mean diameter by the wire diameter and multiply by the winding height.

- Calculating the wire length: Multiply the number of turns by the circumference of the mean diameter.

9. Explain the importance of winding tension control and how it affects the quality of the wound coil?

Winding tension control is crucial as it impacts the following:

- Coil compactness: Proper tension ensures compact winding, preventing loose or tangled coils.

- Electrical performance: Maintains consistent spacing between wire turns, affecting inductance and capacitance.

- Mechanical strength: Adequate tension prevents wire breakage and ensures coil integrity.

- Heat dissipation: Proper tension allows for heat dissipation, preventing overheating.

- Efficiency: Optimizing winding tension reduces energy loss and improves overall efficiency.

10. Describe the different methods used to inspect and test wound coils for quality assurance?

Various inspection and testing methods are used for quality assurance:

- Visual inspection: Checking for physical defects, such as loose windings, damaged insulation, or incorrect dimensions.

- Electrical testing: Measuring resistance, inductance, and capacitance to ensure they meet specifications.

- Hi-pot testing: Applying high voltage to check for insulation integrity and prevent electrical breakdowns.

- Dimensional inspection: Verifying coil dimensions, winding pitch, and overall geometry.

- Microscopic inspection: Examining wire insulation and windings for defects or contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Back Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Back Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Back Winder is a skilled manufacturing professional responsible for operating machines that wind materials onto reels, spools, or other cylindrical forms.

1. Machine Operation

The primary duty of a Back Winder is to operate winding machines accurately and efficiently.

- Set up and calibrate winding machines according to specifications.

- Load and adjust materials, such as yarn, wire, or thread, onto machines.

- Monitor the winding process, ensuring that materials are wound evenly and precisely.

- Make adjustments to machine settings as needed to maintain optimal performance.

2. Quality Control

Back Winders are responsible for maintaining high quality standards in the winding process.

- Inspect materials before and after winding for any defects or irregularities.

- Identify and correct any quality issues with the winding process or materials.

- Record and report quality data as required for quality assurance purposes.

- Follow established quality control procedures and standards.

3. Inventory Management

Back Winders are often involved in inventory management tasks.

- Maintain inventory of materials used in the winding process.

- Track material usage and replenish inventory as needed.

- Monitor inventory levels to prevent shortages or overstocking.

- Store and organize materials in a safe and efficient manner.

4. Equipment Maintenance

Back Winders may be required to perform basic maintenance on winding machines.

- Clean and lubricate machines regularly to ensure proper functioning.

- Identify and report any maintenance issues or malfunctions to supervisors.

- Assist with minor repairs and troubleshooting as needed.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Back Winder position, candidates should prepare thoroughly and demonstrate their skills and experience.

1. Research the Company and Position

Research the company and the specific Back Winder position to gain insights into the company culture, job requirements, and industry trends.

- Visit the company website and social media pages.

- Read industry publications and articles.

- Network with professionals in the industry.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to the specific requirements of the Back Winder position.

- Emphasize your experience in operating winding machines.

- Showcase your attention to detail and commitment to quality.

- Provide examples of your inventory management and equipment maintenance skills.

3. Practice Common Interview Questions

- Prepare answers to common interview questions, such as:

- “Tell me about your experience in operating winding machines.”

- “How do you ensure quality in your work?”

- “What are your strengths and weaknesses as a Back Winder?”

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company.

- Consider asking questions about the company’s growth plans, the specific responsibilities of the Back Winder position, or opportunities for professional development.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive at the interview on time.

- Be polite and respectful to the interviewer.

- Maintain eye contact and speak clearly.

- Follow up with a thank-you note after the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Back Winder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.