Are you gearing up for a career in Baffle Mounter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Baffle Mounter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

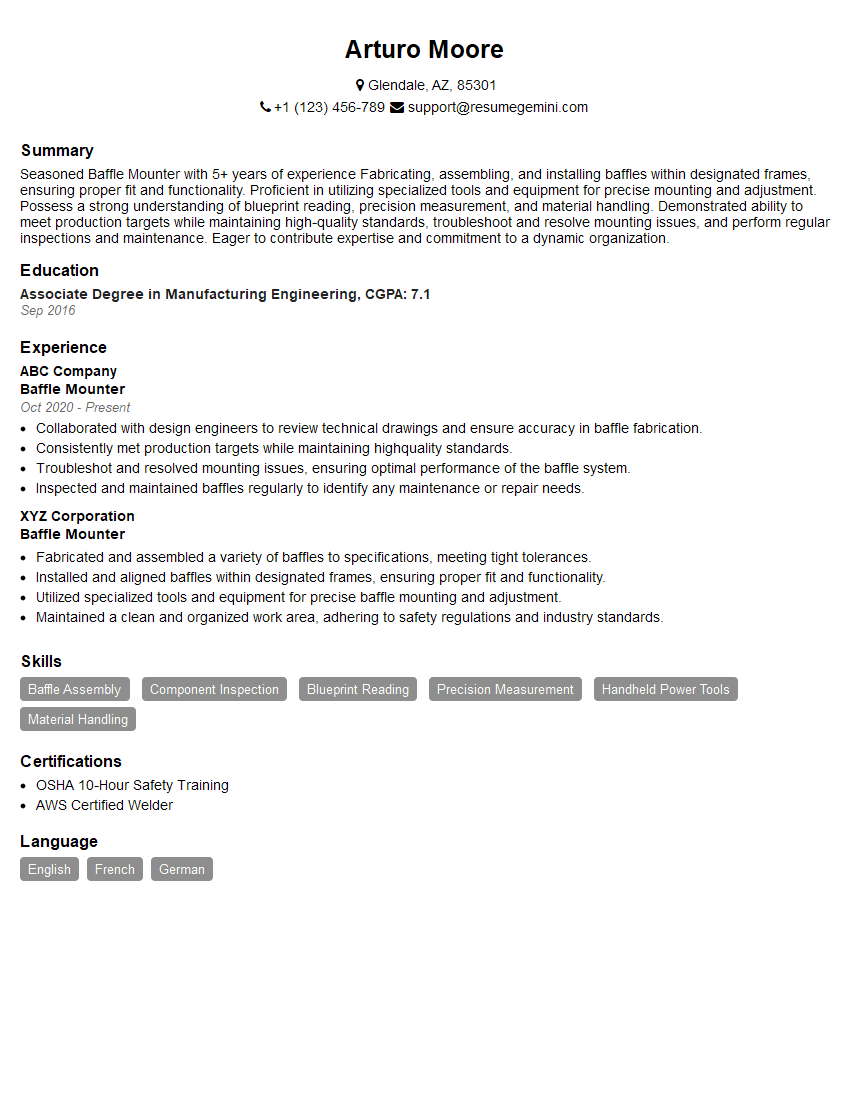

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Baffle Mounter

1. What are the different types of baffles used in HVAC systems, and what are their applications?

- Acoustical baffles: Absorb sound in ductwork, reducing noise transmission.

- Plenum baffles: Control airflow, distribute air evenly, and prevent short-circuiting.

- Return air baffles: Enhance air mixing and prevent stratification.

- Static pressure baffles: Balance airflow in parallel ducts, preventing uneven pressure distribution.

- Smoke control baffles: Guide smoke flow in smoke management systems, preventing its spread.

2. Explain the process of selecting the appropriate baffle for an HVAC system.

Factors to Consider:

- System type and purpose

- Airflow volume and velocity

- Space constraints

- Acoustic requirements

- Fire safety regulations

Selection Process:

- Determine system requirements

- Review baffle types and applications

- Calculate baffle dimensions and performance

- Select baffle material and construction

- Coordinate installation and testing

3. What are the advantages of using baffles in HVAC systems?

- Improve air distribution and uniformity

- Control airflow and prevent short-circuiting

- Reduce noise levels and enhance acoustic comfort

- Balance static pressure and optimize airflow

- Enhance fire safety by guiding smoke flow and preventing its spread

4. Discuss the different materials used for baffle construction, and their respective advantages and disadvantages.

- Metal (steel, aluminum): Durable, fire-resistant, but heavy and may be subject to corrosion.

- Plastic: Lightweight, resistant to corrosion, but not as strong or heat-resistant as metal.

- Fiberglass: Acoustically absorbent, lightweight, but flammable and may deteriorate over time.

- Composite materials: Combine properties of various materials, offering lightweight, strength, and acoustical performance.

5. Describe the manufacturing process of baffles, including the different techniques and equipment used.

Manufacturing Process:

- Material selection and preparation

- Baffle design and fabrication (cutting, forming, welding, etc.)

- Surface treatment (painting, coating, etc.)

- Quality inspection and testing

Techniques and Equipment:

- Sheet metal fabrication equipment (shears, brakes, welders)

- Laser cutting and waterjet cutting for precision and complex shapes

- Injection molding and vacuum forming for plastic baffles

6. Explain the importance of proper installation and maintenance of baffles in HVAC systems.

- Installation: Ensure proper alignment, secure attachment, and compliance with design specifications.

- Maintenance: Regular inspection and cleaning to prevent dust and debris accumulation, ensuring optimal performance.

- Extend the lifespan of baffles and maintain their effectiveness in controlling airflow and acoustics.

7. Discuss the safety precautions and regulations that must be followed when working with baffles in HVAC systems.

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Handle sharp edges and materials with care to avoid cuts and injuries.

- Follow electrical safety procedures when dealing with electrical components.

- Adhere to building codes and fire safety regulations.

- Conduct regular risk assessments and establish safety protocols.

8. Describe the troubleshooting techniques used to diagnose and resolve issues related to baffles in HVAC systems.

Common Issues and Troubleshooting:

- Insufficient airflow: Check for obstructions or misalignment of baffles, clean or replace if necessary.

- Uneven air distribution: Examine baffles for damage or improper installation, adjust or replace as needed.

- Excessive noise: Inspect baffles for defects or damage, replace or repair if required.

- Vibration or rattling: Tighten loose fasteners, add vibration damping materials, or replace damaged baffles.

9. Explain how baffles contribute to energy efficiency in HVAC systems.

- Improve airflow distribution, reducing pressure drop and fan energy consumption.

- Prevent airflow short-circuiting, ensuring uniform cooling or heating throughout the space.

- Reduce thermal stratification, promoting even temperature distribution and reducing energy waste.

- Contribute to overall HVAC system optimization, leading to energy savings.

10. Discuss the future trends and advancements in baffle design and technology.

- Advanced materials: Development of lightweight, durable, and acoustically effective materials.

- Smart baffles: Integration of sensors and controls for real-time monitoring and optimization.

- Computational fluid dynamics (CFD): Enhanced design and analysis of baffles for optimal performance.

- Sustainable materials: Focus on environmentally friendly and recyclable materials.

- Customization: Designing baffles to meet specific project requirements and improve aesthetics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Baffle Mounter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Baffle Mounter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Baffle Mounter plays a crucial role in the manufacturing process. Their primary responsibilities include:

1. Baffle Installation and Assembly

Installing and assembling baffles, which are structural components used in various industries, such as automotive, construction, and aerospace.

- Positioning and aligning baffles according to specified dimensions and tolerances.

- Using hand tools and specialized equipment to secure and fasten baffles.

2. Quality Control and Inspection

Ensuring the quality and accuracy of assembled products.

- Inspecting baffles for defects, such as scratches, dents, or misalignment.

- Adhering to established quality standards and specifications.

3. Material Handling

Handling and moving various materials, such as baffles, brackets, and hardware.

- Loading, unloading, and transporting materials using forklifts or manual labor.

- Storing and organizing materials in designated areas.

4. Workplace Safety

Maintaining a safe and organized work environment.

- Following safety protocols, wearing proper protective gear, and operating equipment responsibly.

- Keeping work areas clean and free of hazards.

Interview Tips

To ace a Baffle Mounter interview, prepare yourself by considering the following tips:

1. Research the Company and Job Role

Demonstrate your interest and knowledge about the company and the specific job requirements. Research the company’s website, social media, and industry-related articles.

- Identify the key responsibilities and skills required for the role.

- Learn about the company’s culture, values, and goals.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your skills and experience that align with the job’s responsibilities. Quantify your accomplishments whenever possible.

- Showcase your experience in baffle installation, assembly, and inspection.

- Highlight your attention to detail, quality consciousness, and ability to meet deadlines.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Practice answering them clearly and concisely.

- Example Outline:

- “Tell me about your experience in baffle installation.”

- Answer: “In my previous role as a Baffle Mounter, I was responsible for assembling and installing baffles in automotive components. I ensured precision and quality by following strict specifications and using specialized tools.”

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows your engagement and interest. Prepare questions related to the company, the job, and the industry.

- Example Outline:

- “What are the company’s plans for future growth in the baffle manufacturing industry?”

- Answer: “We are actively exploring new technologies and partnerships to expand our product offerings and meet the evolving needs of our customers.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Baffle Mounter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!