Are you gearing up for a career in Bag Printer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bag Printer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

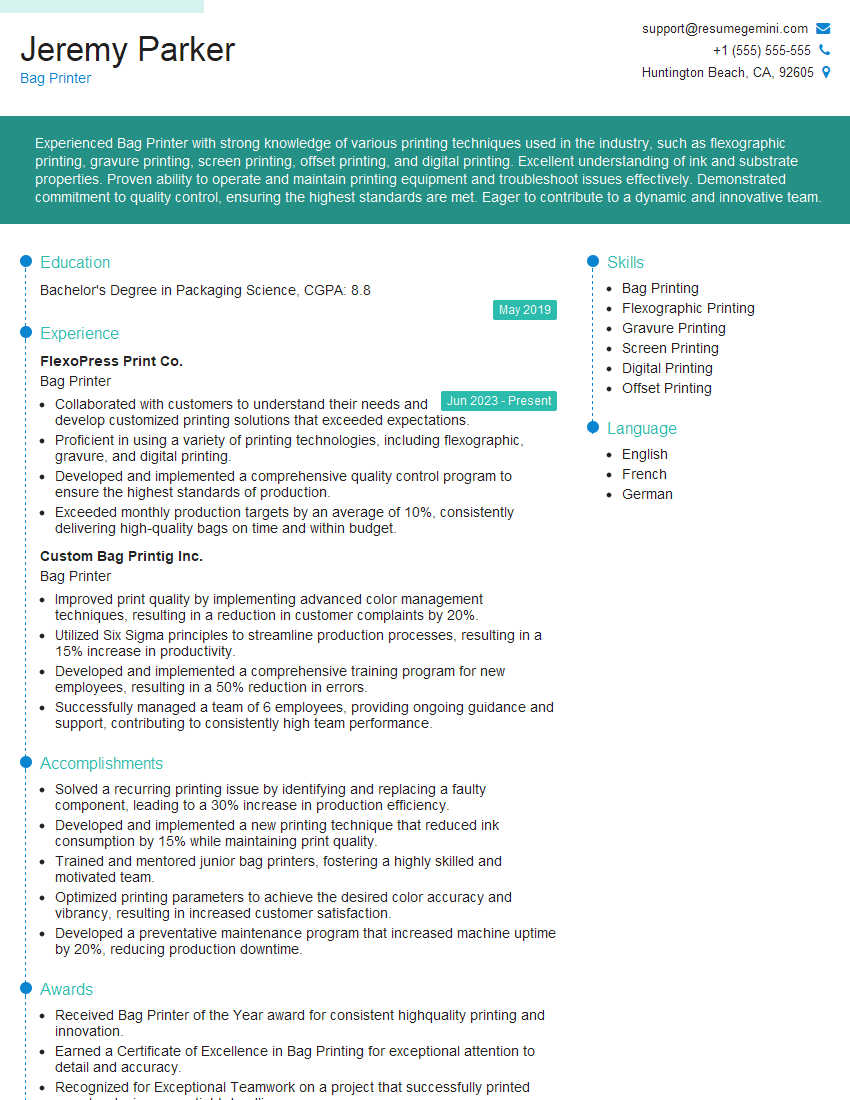

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bag Printer

1. Explain the process of bag printing?

Bag printing starts with prepress, where the design is created and prepared for printing. This involves creating a digital file of the design, which is then used to create printing plates. The printing plates are then mounted on a printing press, which transfers the ink onto the bag material. The bag material is then dried and cured, and the bags are ready for packaging.

- Prepress: Design creation and preparation

- Printing: Transferring ink onto bag material

- Drying and curing: Setting the ink and making the bags ready for packaging

2. What are the different types of bag printing processes?

There are several types of bag printing processes, including:

- Flexographic printing: Uses flexible printing plates to transfer ink onto the bag material

- Gravure printing: Uses engraved cylinders to transfer ink onto the bag material

- Offset printing: Uses a series of rollers to transfer ink from a printing plate to the bag material

- Digital printing: Uses a digital file to directly print onto the bag material

3. What are the key factors that affect the quality of bag printing?

The quality of bag printing is affected by several factors, such as:

- The quality of the printing plates

- The quality of the ink

- The printing press

- The bag material

- The printing environment

4. How do you ensure that the printed bags meet the customer’s specifications?

To ensure that the printed bags meet the customer’s specifications, I:

- Review the customer’s specifications carefully

- Create a detailed production plan

- Monitor the printing process closely

- Conduct quality control checks throughout the process

- Make adjustments to the printing process as needed

5. What are the common problems that can occur during bag printing and how do you solve them?

Some common problems that can occur during bag printing include:

Registration errors

- Cause: Incorrect alignment of the printing plates

- Solution: Adjust the printing plates

Ink smudging

- Cause: Too much ink or poor ink quality

- Solution: Reduce ink flow or use higher quality ink

Color variation

- Cause: Incorrect ink mixing or temperature fluctuations

- Solution: Calibrate the ink mixing system or adjust the temperature

6. What are the latest trends in bag printing technology?

The latest trends in bag printing technology include:

- Digital printing: Enables on-demand printing and customization

- Sustainable printing: Uses eco-friendly inks and materials

- Automation: Reduces manual labor and improves efficiency

- 3D printing: Creates three-dimensional printed bags

7. What is your experience with different types of bag printing machines?

I have experience operating various types of bag printing machines, including:

- Flexographic printing presses

- Gravure printing presses

- Offset printing presses

- Digital printing machines

8. How do you maintain and troubleshoot bag printing machines?

To maintain and troubleshoot bag printing machines, I:

- Perform regular maintenance checks

- Identify and resolve common issues

- Troubleshoot complex problems

- Collaborate with maintenance technicians

9. What are your strengths and weaknesses as a Bag Printer?

My strengths as a Bag Printer include:

- Excellent technical skills

- Strong attention to detail

- Ability to work independently and as part of a team

- Commitment to quality and customer satisfaction

My weaknesses include:

- Limited experience with some newer printing technologies

- Occasional difficulty meeting tight deadlines

10. Why are you interested in working as a Bag Printer?

I am interested in working as a Bag Printer because I am passionate about printing and packaging. I enjoy the technical aspects of bag printing and I am always looking for ways to improve my skills. I am also a team player and I am eager to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bag Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bag Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bag Printer plays a vital role in ensuring that bags used for packaging meet the required specifications. Their responsibilities include meticulously following printing instructions, monitoring print quality, and performing regular maintenance on printing equipment.

1. Execute Printing Instructions

Bag Printers are responsible for receiving printing instructions and executing them precisely. They ensure that the correct inks, plates, and materials are used for each job. They execute the print production process, maintaining the required standards and adhering to deadlines.

- Operate printing machines and equipment

- Set up, adjust, and change printing plates

- Mix and prepare inks according to specifications

- Load and unload paper or bags into the printing press

2. Monitor Print Quality

Bag Printers have a keen eye for detail and are responsible for monitoring the print quality throughout the production process. They inspect printed bags for any defects or errors, ensuring that the finished product meets the desired standards.

- Check printed bags for color accuracy, sharpness, and registration

- Identify and correct printing errors

- Calibrate printing equipment to maintain consistent print quality

- Maintain records of print quality

3. Perform Equipment Maintenance

To ensure optimal performance, Bag Printers are responsible for performing regular maintenance and cleaning of printing equipment. They follow maintenance schedules, lubricate moving parts, and replace worn or damaged components.

- Lubricate and clean printing presses and other equipment

- Replace worn or damaged parts

- Inspect and maintain printing plates

- Troubleshoot and resolve minor equipment issues

4. Other Responsibilities

In addition to the core responsibilities, Bag Printers may also be involved in other tasks.

- Assist in developing and testing new printing processes

- Train new employees on printing techniques

- Maintain a clean and organized work area

- Follow safety procedures and regulations

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Bag Printer position:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will give you a better understanding of the company’s culture, values, and the responsibilities of the position. It will also help you tailor your answers to the interviewer’s questions.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner, highlighting your skills and experience that are relevant to the job.

3. Highlight Your Attention to Detail

Bag Printers must have a keen eye for detail to ensure the quality of printed bags. In your interview, be sure to emphasize your attention to detail and provide examples of times when you have successfully identified and corrected errors.

4. Showcase Your Problem-Solving Skills

Bag Printers may encounter problems with printing equipment or print quality. In your interview, demonstrate your problem-solving skills by describing a time when you successfully identified and resolved a problem.

5. Be Prepared to Discuss Your Experience with Printing Equipment

If you have experience with printing equipment, be sure to highlight this in your interview. Describe the specific types of equipment you have worked with and the tasks you have performed.

6. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for your interview. Punctuality is also important, so arrive on time for your scheduled interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bag Printer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!