Are you gearing up for a career in Bag Valver? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bag Valver and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bag Valver

1. Describe the process of bagging and sealing bags on the bag valving machine?

The process of bagging and sealing bags on a bag valving machine involves the following steps:

- The empty bag is placed on the bagging spout.

- The bag is inflated with air to open it up and remove any creases.

- The product is dispensed into the bag.

- The bag is sealed by heat sealing the top of the bag.

- The sealed bag is removed from the bagging spout.

2. How do you ensure that the bags are filled to the correct weight?

Checking the weight of each bag

- The weight of each bag is checked using a scale.

- If the bag is underweight, more product is added.

- If the bag is overweight, some product is removed.

Calibrating the bagging machine

- The bagging machine is calibrated to ensure that it is dispensing the correct amount of product.

- The calibration is checked regularly to ensure that the machine is accurate.

3. What are the different types of bagging machines?

There are many different types of bagging machines, each with its own advantages and disadvantages. The most common types of bagging machines are:

- Vertical form fill seal (VFFS) machines

- Horizontal form fill seal (HFFS) machines

- Pre-made bagging machines

- Bagging scales

4. What are the factors to consider when selecting a bagging machine?

The following factors should be considered when selecting a bagging machine:

- The type of product to be bagged

- The desired bag size and shape

- The production speed

- The accuracy required

- The budget

5. What are the common problems that can occur with bagging machines?

The following are some of the common problems that can occur with bagging machines:

- Bags not opening properly

- Bags not filling properly

- Bags not sealing properly

- Machine jams

- Electrical problems

6. How do you troubleshoot and resolve problems with bagging machines?

The following steps can be taken to troubleshoot and resolve problems with bagging machines:

- Identify the problem.

- Check for any obvious causes of the problem, such as loose wires or jammed parts.

- Refer to the machine’s manual for troubleshooting tips.

- Contact the machine manufacturer for technical support.

7. What are the safety precautions that should be taken when operating a bagging machine?

The following safety precautions should be taken when operating a bagging machine:

- Wear appropriate safety clothing, such as gloves and safety glasses.

- Keep hands and loose clothing away from moving parts.

- Do not operate the machine if it is damaged.

- Follow all manufacturer’s instructions.

8. What are the maintenance requirements for a bagging machine?

The following maintenance tasks should be performed on a regular basis to keep a bagging machine running smoothly:

- Clean the machine regularly.

- Inspect the machine for any signs of wear or damage.

- Lubricate the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly.

9. What are the advantages of using a bagging machine?

The following are some of the advantages of using a bagging machine:

- Increased efficiency

- Improved accuracy

- Reduced labor costs

- Improved product quality

- Increased safety

10. What are the disadvantages of using a bagging machine?

The following are some of the disadvantages of using a bagging machine:

- High initial investment cost

- Ongoing maintenance costs

- Can be complex to operate

- Can be noisy

- Can take up a lot of space

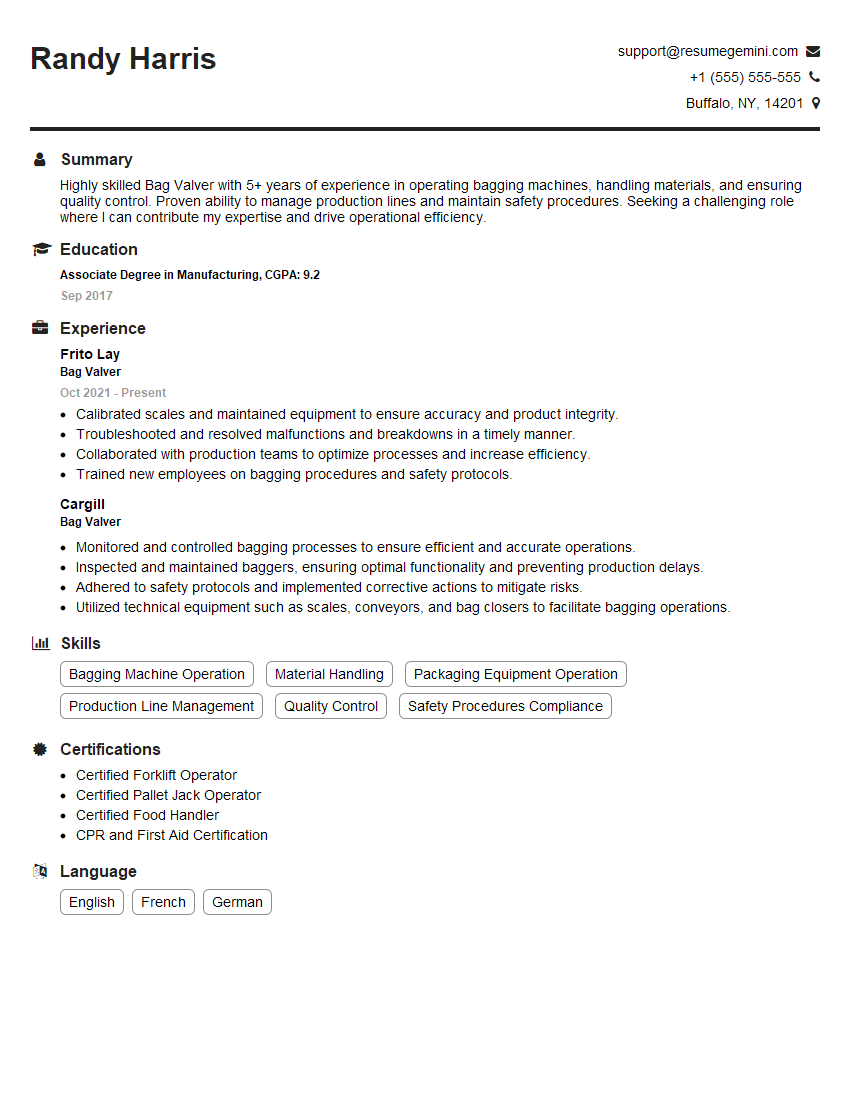

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bag Valver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bag Valver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bag Valvers are responsible for operating and maintaining bagging equipment, which packages products into bags. They ensure that the machinery runs smoothly, fills bags accurately, and produces quality packages. The primary responsibilities of a Bag Valver include:

1. Operating Bagging Equipment

Bag Valvers are responsible for setting up, operating, and maintaining bagging equipment. They ensure that the machines are running smoothly and efficiently, and they make adjustments as needed to ensure product quality.

- Set up and operate bagging machines

- Adjust machine settings to ensure proper bag filling and sealing

- Monitor machine performance and make adjustments as needed

2. Bag Filling and Sealing

Bag Valvers are responsible for filling bags with the correct amount of product and sealing them securely. They must ensure that the bags are filled to the correct weight or volume, and that the seals are tight and secure.

- Fill bags with product

- Seal bags to prevent leakage

- Inspect bags for defects

3. Quality Control

Bag Valvers are responsible for ensuring that the bags they produce meet quality standards. They inspect the bags for defects, such as holes or tears, and they weigh the bags to ensure that they contain the correct amount of product.

- Inspect bags for defects

- Weigh bags to ensure correct weight

- Reject bags that do not meet quality standards

4. Equipment Maintenance

Bag Valvers are responsible for maintaining the bagging equipment they use. They perform regular cleaning and maintenance tasks, and they troubleshoot and repair minor problems as they arise.

- Clean and maintain bagging equipment

- Troubleshoot and repair minor problems

- Report major problems to maintenance

Interview Tips

To ace your interview for a Bag Valver position, it’s important to prepare thoroughly and demonstrate your skills and experience. Here are some interview tips to help you succeed:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Bag Valver position you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job.

- Visit the company’s website and social media pages

- Read industry news articles and reports

- Talk to people in your network who work in the industry

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s important to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Write out your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Highlight Your Skills and Experience

The interview is your chance to showcase your skills and experience, and to demonstrate why you’re the right person for the job. Be sure to highlight your relevant skills and experience in your resume and cover letter, and be prepared to talk about them in detail during the interview.

- Quantify your accomplishments and provide specific examples

- Use keywords from the job description in your answers

- Be enthusiastic and positive about your skills and experience

4. Be Prepared to Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your chance to learn more about the company and the position, and to show that you’re interested and engaged.

- Prepare a few thoughtful questions to ask the interviewer

- Ask questions about the company culture, the position, and the industry

- Avoid asking questions that are only about salary or benefits

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bag Valver, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bag Valver positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.