Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bagging Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bagging Machine Operator so you can tailor your answers to impress potential employers.

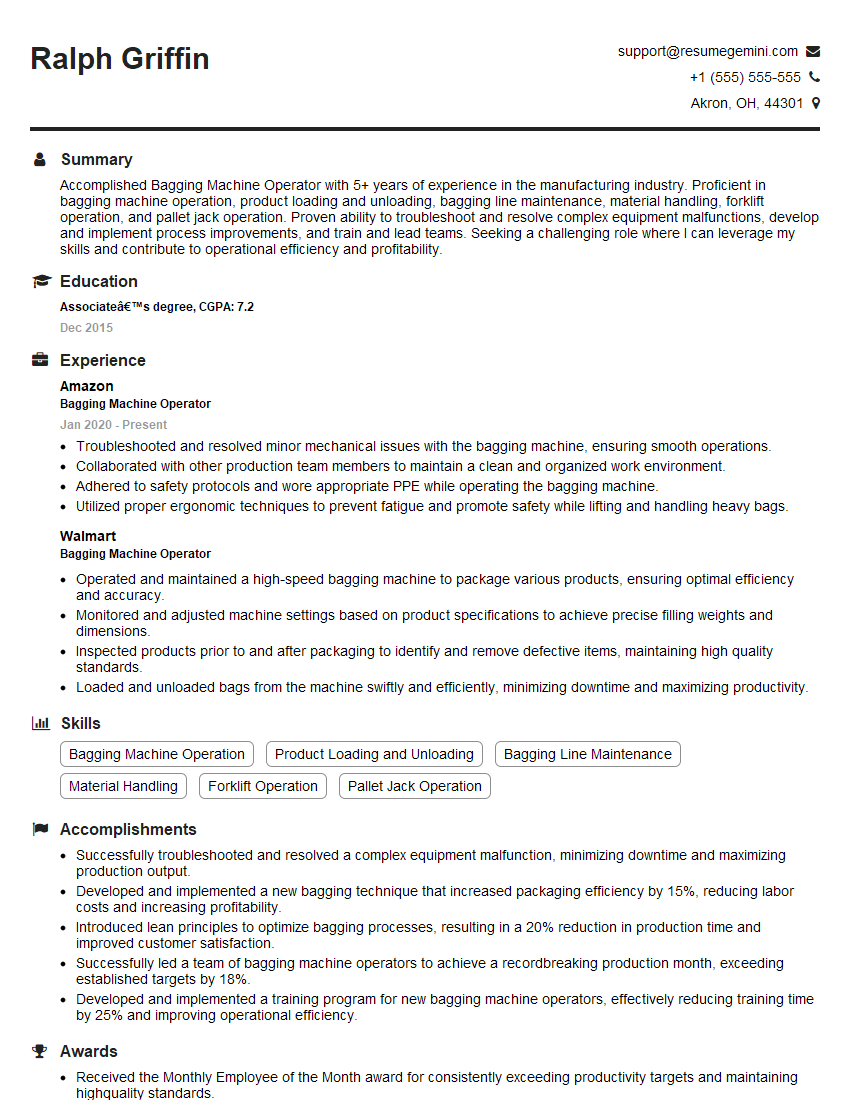

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bagging Machine Operator

1. What are the different types of bagging machines and which one is most suitable for a specific application?

There are several types of bagging machines, each with its advantages and disadvantages. The most suitable type for a specific application depends on factors such as the type of product, the desired bag size and shape, and the production speed required. Here are some common types of bagging machines:

- Vertical Form Fill Seal (VFFS) machines: These machines create bags from a roll of film and fill them with product before sealing them closed. They are versatile and can handle a wide range of products and bag sizes.

- Horizontal Form Fill Seal (HFFS) machines: These machines form bags from a flat sheet of film and fill them with product before sealing them closed. They are suitable for high-speed applications and can handle a variety of products.

- Pre-made bagging machines: These machines fill pre-made bags with product and seal them closed. They are often used for products that are sensitive to contamination or that require a specific bag size or shape.

2. How to troubleshoot a bagging machine?

1. Check the power supply

- Make sure that the machine is properly plugged in and that the power switch is turned on.

2. Check the air supply

- Make sure that the machine is connected to a compressed air supply and that the air pressure is within the specified range.

3. Check the product supply

- Make sure that there is product in the hopper and that it is flowing smoothly into the bagging machine.

4. Check the bagging machine settings

- Make sure that the bagging machine settings are correct for the type of product and bag size being used.

5. Check the bagging machine for blockages

- Check the bagging machine for any blockages that may be preventing the product from flowing smoothly into the bags.

6. Check the bagging machine for leaks

- Check the bagging machine for any leaks that may be causing the bags to be filled with air or product.

3. What are the safety procedures that must be followed when operating a bagging machine?

The safety procedures that must be followed when operating a bagging machine vary depending on the specific machine, but some common procedures include:

- Keep hands and other body parts away from moving parts.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Do not operate the machine if it is damaged or malfunctioning.

- Do not attempt to clear jams or blockages while the machine is running.

- Follow all lockout/tagout procedures before performing any maintenance or repairs.

4. What are the maintenance procedures that must be followed to keep a bagging machine in good working order?

The maintenance procedures that must be followed to keep a bagging machine in good working order vary depending on the specific machine, but some common procedures include:

- Clean the machine regularly to remove dust and debris.

- Lubricate the moving parts as per the manufacturer’s instructions.

- Inspect the machine for wear and tear on a regular basis.

- Calibrate the machine as needed to ensure accuracy.

- Follow all manufacturer’s instructions for maintenance and repairs.

5. What are the different types of bags that can be used on a bagging machine?

The different types of bags that can be used on a bagging machine vary depending on the specific machine, but some common types include:

- Polyethylene bags: These bags are made from a lightweight, flexible plastic and are often used for packaging food and other products.

- Polypropylene bags: These bags are made from a stronger, more durable plastic and are often used for packaging heavy or sharp objects.

- Paper bags: These bags are made from a variety of paper materials and are often used for packaging food and other products.

- Woven bags: These bags are made from a woven fabric and are often used for packaging heavy or bulky objects.

6. How to adjust the bagging machine to accommodate different bag sizes?

There are two methods of adjusting the bagging machine to accommodate different bag sizes:

- Adjusting the bag length: This may involve changing the length of the bag film or adjusting the position of the sealing jaws.

- Adjusting the bag width: This may involve adjusting the width of the bag film or adjusting the position of the side sealers.

- In addition, you may also need to adjust the machine’s settings for product volume and sealing temperature.

7. How to troubleshoot a bagging machine that is not filling bags correctly?

There are several reasons why a bagging machine may not be filling bags correctly. Some of the most common causes include:

- The product supply is not consistent.

- The bagging machine is not set up correctly for the type of product being used.

- The bagging machine is not calibrated correctly.

- There is a blockage in the bagging machine.

- The bagging machine is not properly maintained.

8. How to troubleshoot a bagging machine that is not sealing bags correctly?

There are several reasons why a bagging machine may not be sealing bags correctly. Some of the most common causes include:

- The sealing jaws are not aligned correctly.

- The sealing jaws are not hot enough.

- The sealing jaws are not clean.

- The bag material is not compatible with the sealing method being used.

- The bagging machine is not properly maintained.

9. What are the different types of sensors that can be used on a bagging machine?

There are several different types of sensors that can be used on a bagging machine, including:

- Photoelectric sensors: These sensors use a light beam to detect the presence of objects.

- Proximity sensors: These sensors use a magnetic field to detect the presence of metal objects.

- Capacitive sensors: These sensors use a capacitive field to detect the presence of objects.

- Ultrasonic sensors: These sensors use ultrasonic waves to detect the presence of objects.

10. How to program a bagging machine?

The programming of a bagging machine can vary depending on the specific machine, but some common steps include:

- Select the desired bag size and type.

- Set the machine’s speed and other operating parameters.

- Create a product recipe that specifies the product weight or volume to be filled into each bag.

- Start the machine and monitor its operation to ensure that it is functioning properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bagging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bagging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bagging Machine Operators are responsible for operating and maintaining bagging machines, ensuring smooth and efficient operations in production facilities.

1. Machine Operation and Monitoring

Operate bagging machines to fill and seal bags, accurately and consistently.

- Monitor machine performance, identify potential issues, and take corrective actions to maintain optimal operation.

- Check bag quality, ensuring they meet customer specifications and industry standards.

2. Materials Handling

Handle and load materials, such as bags, packaging supplies, and products, to the bagging machine.

- Feed products into the machine, ensuring proper orientation and alignment.

- Maintain proper inventory levels and coordinate with other departments for material replenishment.

3. Maintenance and Repairs

Perform basic maintenance and repairs on bagging machines, ensuring their smooth functioning.

- Clean and lubricate equipment regularly to prevent breakdowns.

- Troubleshoot minor issues and make adjustments as needed to maintain optimal performance.

- Report major issues to supervisors for timely repairs or replacements.

4. Safety and Compliance

Follow safety protocols and maintain a clean and organized work area.

- Wear appropriate personal protective equipment (PPE) at all times.

- Adhere to workplace health and safety regulations and industry best practices.

Interview Tips

Preparing for a Bagging Machine Operator interview requires a combination of technical knowledge and interview preparation strategies. Here are some crucial tips to help you ace the interview:

1. Research the Company and Role

Gather information about the company, its products or services, and the specific requirements of the Bagging Machine Operator role. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Relevant Experience

Emphasize your previous experience operating and maintaining bagging machines, including any specific equipment models you have worked with. Quantify your accomplishments with measurable results to showcase your impact on productivity and efficiency.

3. Demonstrate Attention to Detail

Bagging Machine Operators must be meticulous in their work. Highlight your strong attention to detail and ability to identify and resolve potential issues before they impact production.

4. Prepare for Technical Questions

Expect questions about the operation, maintenance, and troubleshooting of bagging machines. Be prepared to discuss your understanding of different types of bagging equipment, common problems, and your approach to resolving them.

5. Practice Common Interview Questions

Rehearse answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Prepare clear and concise responses that align with the job requirements.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and demonstrates your punctuality and reliability.

7. Ask Thoughtful Questions

Prepare a few thoughtful questions to ask the interviewer at the end of the interview. This demonstrates your engagement and interest in the role. Examples include questions about the company’s growth plans, sustainability initiatives, or opportunities for professional development.

8. Follow Up and Thank the Interviewer

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and express your appreciation for their time. This shows gratitude and professionalism.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bagging Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bagging Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.