Feeling lost in a sea of interview questions? Landed that dream interview for Balance Weigher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Balance Weigher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

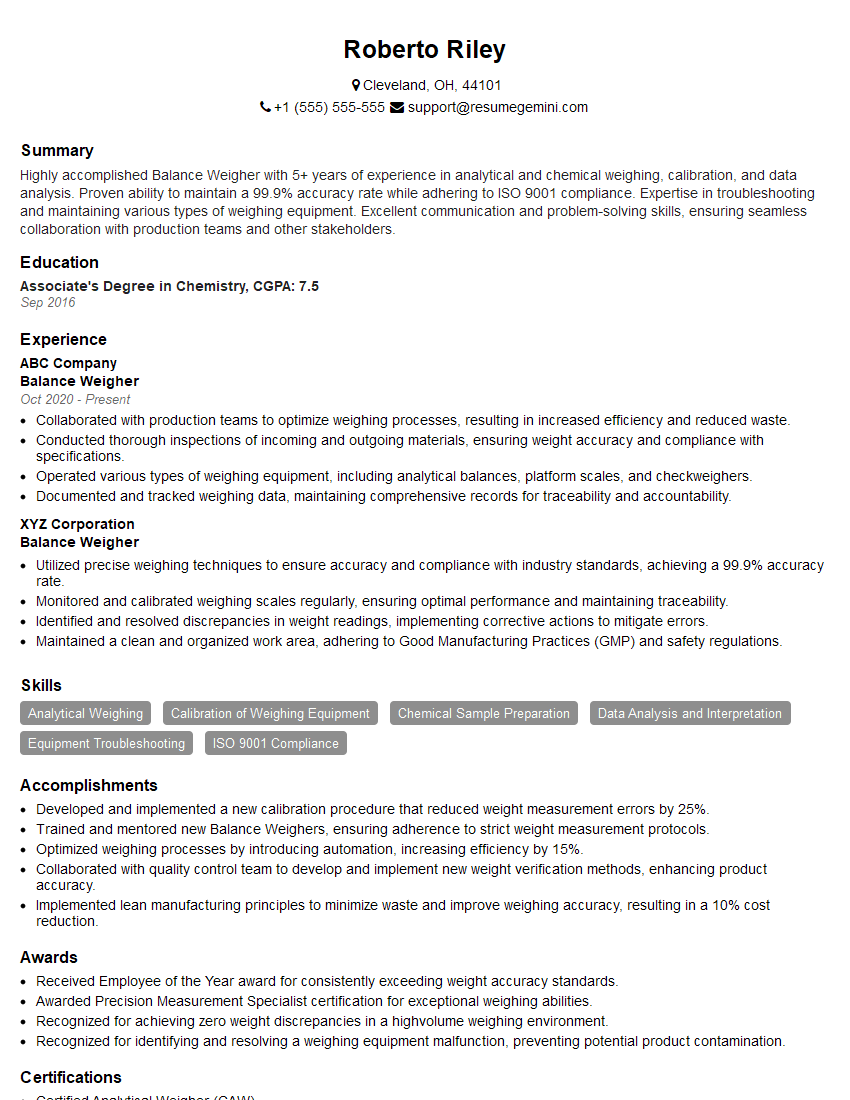

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Balance Weigher

1. Explain the process of calibrating a balance?

Sample Answer:

- Turn on the balance and allow it to warm up for the specified time.

- Place the calibration weight on the balance pan.

- Press the “Calibrate” button.

- The balance will display a message indicating that the calibration is complete.

- Remove the calibration weight.

2. What are the different types of balances and their uses?

Types of Balances

- Analytical balances are used for precise weighing of small samples, typically in the range of 0.0001 to 0.1 grams.

- Top-loading balances are used for weighing larger samples, typically in the range of 1 to 1000 grams.

- Platform balances are used for weighing large, heavy objects, typically in the range of 1000 to 10,000 grams.

Uses of Balances

- Analytical balances are used in laboratories for research and development, quality control, and other applications where precise weighing is required.

- Top-loading balances are used in industrial settings for weighing raw materials, finished products, and other items.

- Platform balances are used in warehouses and other settings for weighing large, heavy objects.

3. What is the difference between accuracy and precision?

- Accuracy refers to how close a measurement is to the true value.

- Precision refers to how consistent a measurement is.

A measurement can be precise without being accurate, and it can be accurate without being precise. For example, a balance that consistently measures a weight to be 100 grams may not be accurate if the true weight is 105 grams. However, a balance that consistently measures a weight to be 105 grams is both accurate and precise.

4. What are some factors that can affect the accuracy of a balance?

- Temperature

- Humidity

- Vibration

- Air currents

- Electrostatic discharge

It is important to take these factors into account when using a balance to ensure that the measurements are accurate.

5. How do you troubleshoot a balance that is not weighing accurately?

- Check the calibration

- Check the environment

- Check the sample

- Contact the manufacturer

By following these steps, you can troubleshoot a balance that is not weighing accurately and ensure that it is functioning properly.

6. What are the safety precautions that should be taken when using a balance?

- Do not overload the balance

- Do not place hot objects on the balance pan

- Do not use the balance in a hazardous environment

- Keep the balance clean

- Follow the manufacturer’s instructions

By following these safety precautions, you can help to prevent accidents and ensure that the balance is used properly.

7. What are the different types of weighing paper and their uses?

- General-purpose weighing paper is made from a thin, absorbent material and is used for weighing solids.

- Anti-static weighing paper is made from a material that dissipates static electricity and is used for weighing powders and other materials that are prone to static build-up.

- Glassine weighing paper is made from a smooth, non-absorbent material and is used for weighing liquids.

It is important to choose the right type of weighing paper for the material being weighed to ensure accurate results.

8. What is the difference between a tare weight and a gross weight?

- Tare weight is the weight of the empty container that is being used to hold the sample.

- Gross weight is the weight of the container plus the sample.

The tare weight must be subtracted from the gross weight to obtain the net weight of the sample.

9. What are some tips for weighing samples accurately?

- Use the correct balance for the sample size and weight range

- Calibrate the balance regularly

- Zero the balance before each weighing

- Use the correct weighing technique

- Record the results accurately

By following these tips, you can ensure that you are weighing samples accurately and consistently.

10. What are some common mistakes that people make when weighing samples?

- Not calibrating the balance regularly

- Not zeroing the balance before each weighing

- Using the wrong weighing technique

- Not recording the results accurately

- Weighing samples in an unstable environment

By avoiding these common mistakes, you can ensure that you are weighing samples accurately and consistently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Balance Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Balance Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Balance Weighers are responsible for ensuring the accuracy of weighing scales and balances in various settings such as laboratories, manufacturing facilities, and retail stores. They play a crucial role in maintaining the quality and safety of products.

1. Calibration and Maintenance of Weighing Equipment

Balance Weighers calibrate and maintain various types of weighing equipment, including analytical balances, top-loading balances, and precision scales. They follow established procedures to ensure that the equipment meets the required accuracy and precision standards.

2. Weighing and Measuring

They weigh and measure materials, products, and substances accurately using calibrated weighing equipment. This involves determining the weight or mass of samples, ingredients, or products.

3. Data Recording and Analysis

Balance Weighers record and analyze weighing data to ensure accuracy and consistency. They maintain records of weighing results and may use statistical methods to monitor equipment performance and identify any potential issues.

4. Quality Control and Compliance

They contribute to quality control programs by ensuring that weighing processes meet established standards and regulations. They may also participate in audits and inspections to verify the accuracy and reliability of weighing equipment.

5. Troubleshooting and Problem-Solving

Balance Weighers troubleshoot and resolve issues related to weighing equipment. They diagnose problems, perform repairs, and ensure that the equipment is functioning correctly.

6. Safety and Compliance

They adhere to safety guidelines and regulatory requirements related to the use and handling of hazardous materials or substances during weighing operations.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and qualifications. Here are some tips to help you ace the interview for a Balance Weigher position:

1. Research the Role and Company

Familiarize yourself with the specific responsibilities of a Balance Weigher and the company you are applying to. Research their products, services, and industry standing.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in calibration, maintenance, and weighing procedures. Highlight your experience in using various types of weighing equipment and your ability to ensure accuracy.

3. Prepare for Behavioral Questions

Practice answering common behavioral interview questions such as “Tell me about a time you solved a problem” or “Describe a situation where you demonstrated attention to detail.”

4. Demonstrate Problem-Solving Abilities

Share examples of how you have successfully troubleshooted and resolved issues related to weighing equipment. Explain your approach to problem-solving and decision-making.

5. Be Confident and Enthusiastic

Project a positive and confident demeanor during the interview. Show enthusiasm for the role and express your interest in contributing to the company’s success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Balance Weigher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Balance Weigher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.