Feeling lost in a sea of interview questions? Landed that dream interview for Baler Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Baler Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

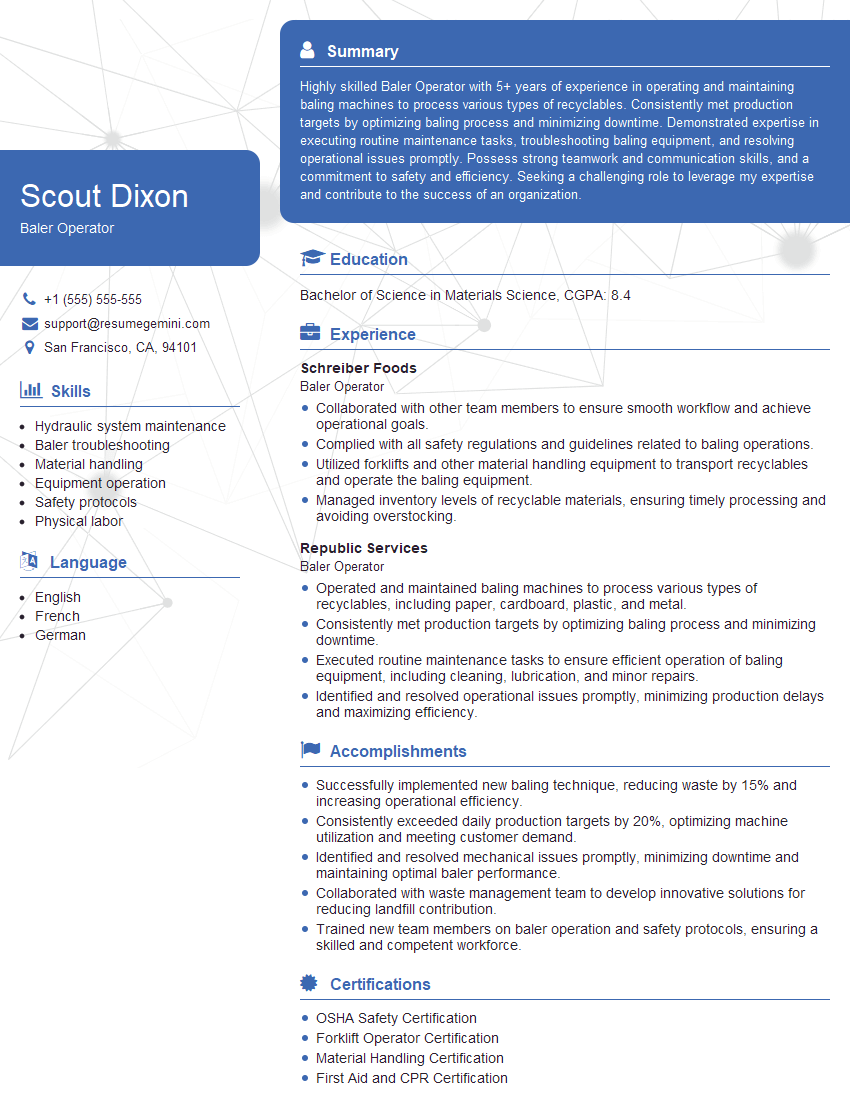

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Baler Operator

1. What are the different types of balers and their uses?

There are various types of balers, each designed for specific materials and applications:

- Horizontal Balers: Process large volumes of recyclable materials such as cardboard, paper, plastic, and metal cans.

- Vertical Balers: Used for smaller volumes of materials and are commonly found in retail, office, and medical settings.

- Two-Ram Balers: Powerful balers designed for dense materials such as scrap metal, rubber, and plastics.

- Shear Balers: Cut materials into smaller pieces before baling, making them ideal for bulky items like mattresses and furniture.

- Round Balers: Create cylindrical bales of hay, straw, and other agricultural products.

2. What are the key safety considerations when operating a baler?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including gloves, safety glasses, and ear protection.

Machine Operation

- Never operate the baler without proper training and authorization.

- Ensure the machine is properly maintained and inspected before use.

- Keep the work area clear of obstructions and follow lockout/tagout procedures.

- Be aware of pinch points and moving parts, and keep hands away from danger zones.

Material Handling

- Inspect materials before baling to remove any foreign objects or hazards.

- Load materials evenly and securely to prevent jamming or imbalances.

3. How do you troubleshoot common baler problems, such as jamming or low bale density?

- Jamming: Clear the jammed material, check for any obstructions in the chamber, and inspect the ram for any damage.

- Low Bale Density: Tighten the platen bolts, adjust the ram pressure settings, or inspect the hydraulic system for leaks.

- Uneven Bales: Check the material distribution within the chamber and adjust the loading process accordingly.

- Broken Straps: Replace the straps promptly using the appropriate technique.

4. What are the best practices for maintaining and servicing a baler?

Regular maintenance ensures optimal performance and safety:

- Lubricate moving parts as per the manufacturer’s instructions.

- Inspect belts, chains, and hydraulic hoses for damage or wear.

- Clean the machine regularly to prevent material buildup.

- Perform routine safety checks, including emergency stop functionality and sensor alignment.

- Follow the manufacturer’s maintenance schedule for major servicing and component replacements.

5. How do you calculate the weight of a baled material?

Calculating the weight of a baled material involves:

- Determining the density of the material.

- Measuring the bale’s dimensions.

- Using the formula: Weight = Density x Volume (Volume = Length x Width x Height)

6. What are the different types of baling wire and their applications?

- High-Tensile Wire: Strong and durable, suitable for baling heavy or dense materials like scrap metal.

- Low-Tensile Wire: Used for lighter materials like cardboard, paper, and plastics.

- Galvanized Wire: Corrosion-resistant for outdoor applications.

- Plastic Strapping: Durable and lightweight, often used for securing bales of agricultural products.

7. How do you handle and store baled materials safely?

- Securely stack bales to prevent toppling.

- Use pallets or dunnage to elevate bales and protect them from moisture.

- Store bales in a dry and well-ventilated area.

- Follow proper lifting techniques when handling bales.

8. What is your experience with different types of balers, including their capacities and features?

Describe your experience with specific models and brands, emphasizing your understanding of their capabilities and advantages.

- Provide examples of how you optimized baler performance and maximized productivity.

9. How do you stay updated with the latest advancements in baling technology?

- Attend industry events and conferences.

- Read trade publications and technical journals.

- Seek training and certification from manufacturers.

- Network with other professionals in the field.

10. Why are you interested in this Baler Operator position, and how do you believe your skills and experience make you a suitable candidate?

Highlight your passion for the industry, your technical proficiency, and your commitment to safety and efficiency.

- Explain how your previous experience aligns with the specific requirements of the role.

- Express your enthusiasm for contributing to the organization’s goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Baler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Baler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Baler Operator is responsible for operating and maintaining baling equipment in a recycling or waste management facility.

1. Bale and Handle Materials

The primary duty of a Baler Operator is to operate balers to compress recyclable materials, such as cardboard, plastic, and paper, into bales.

- Load materials into the baler, ensuring that they are evenly distributed

- Operate the baler to compress materials into bales

- Unload bales from the baler and stack them for storage

2. Inspect and Maintain Equipment

Baler Operators are also responsible for maintaining the baling equipment they operate.

- Inspect balers for damage or wear and tear

- Perform basic maintenance tasks, such as greasing and tightening bolts

- Report any major issues to a supervisor

3. Monitor Production

Baler Operators are responsible for monitoring the production of bales.

- Keep track of the number of bales produced

- Identify any problems that may affect production

- Take steps to increase production, such as adjusting the baler settings

4. Follow Safety Regulations

Baler Operators must follow all safety regulations to ensure their own safety and the safety of others.

- Wear appropriate safety gear, such as gloves and safety glasses

- Never operate a baler that is damaged or malfunctioning

- Follow proper lockout/tagout procedures

Interview Tips

To perform well in a Baler Operator interview, it is important to be prepared and to demonstrate your knowledge and skills.

1. Research the Company and Position

Before going to an interview, take the time to learn about the company and the specific position you are applying for.

- Visit the company website

- Read the job description

- Check out the company on social media

2. Highlight Relevant Experience and Skills

In your interview, be sure to emphasize your relevant experience and skills.

- If you have operated balers in the past, be sure to mention this in your resume and interview.

- Highlight any other relevant skills, such as mechanical ability or customer service skills

- If you have any certifications, such as a forklift certification, be sure to mention these as well

3. Prepare for Common Interview Questions

There are a number of common interview questions that you are likely to be asked in a Baler Operator interview.

- Why are you interested in this position?

- What experience do you have operating balers?

- What are your strengths and weaknesses as a Baler Operator?

- What is your availability?

- What are your salary expectations?

4. Be Enthusiastic and Professional

Finally, it is important to be enthusiastic and professional throughout the interview process.

- Arrive on time for your interview

- Dress appropriately

- Make eye contact with the interviewer

- Speak clearly and confidently

- Be prepared to ask questions about the position and the company

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Baler Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.