Are you gearing up for a career in Baling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Baling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

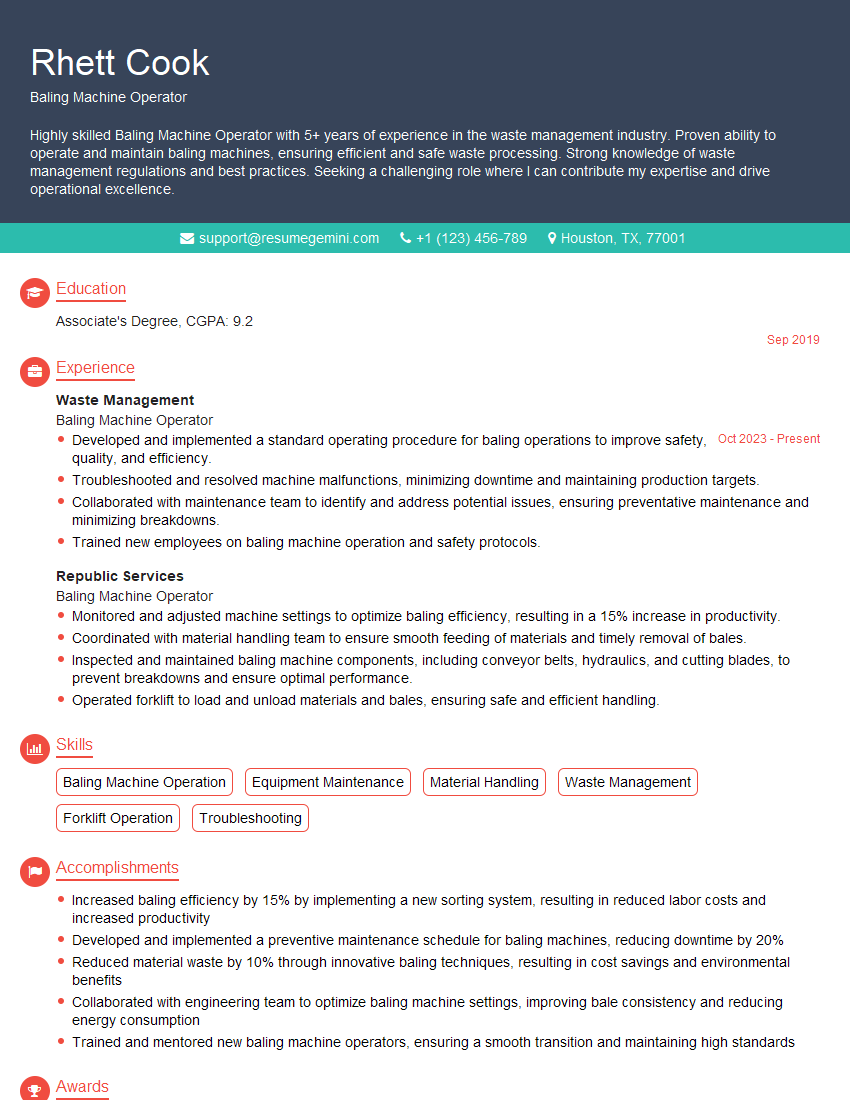

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Baling Machine Operator

1. What are the key responsibilities of a Baling Machine Operator?

As a skilled Baling Machine Operator, I am responsible for:

- Operating baling machines to compress and bale various materials, such as paper, cardboard, plastic, and metals.

- Preparing and loading materials into the baling machine, ensuring proper loading techniques to optimize bale quality.

- Monitoring the baling process, adjusting machine settings, and troubleshooting any operational issues to maintain efficient production.

- Maintaining the baling machine and surrounding work area, ensuring cleanliness and safety.

- Communicating with other team members, supervisors, and clients to coordinate operations and resolve any queries.

2. Describe the different types of baling machines and their specific functions.

Types of Baling Machines

- Vertical Balers: Suitable for high-volume baling of materials like cardboard, paper, and plastics. They compress materials vertically into dense bales.

- Horizontal Balers: Ideal for baling large volumes of loose materials, such as scrap metal, textiles, and plastics. They compress materials horizontally.

- Semi-Automatic Balers: Require manual loading but have automated tying and ejection systems, increasing efficiency.

- Fully-Automatic Balers: Highly efficient, with automated loading, baling, and ejection processes.

Functions

- Baling machines compress materials into dense bales, reducing volume and facilitating storage, transportation, and recycling.

- They enhance safety by eliminating loose materials that can cause tripping hazards or fire risks.

- Baling machines contribute to environmental sustainability by reducing waste and promoting recycling efforts.

3. What factors should be considered when selecting the appropriate baling machine for a specific application?

- Material Type: Different balers are designed for specific materials, such as paper, plastic, metal, or textiles.

- Volume and Density: The baler’s capacity and compression force should match the volume and density of the materials being baled.

- Throughput Requirements: Consider the desired production rate and choose a baler with sufficient throughput.

- Space Availability: The size and footprint of the baler should fit within the designated work area.

- Automation Level: Determine the level of automation required, from manual loading to fully automated systems.

- Budget: Consider the initial cost of the baler as well as ongoing maintenance and operating expenses.

4. Explain the importance of proper bale handling and storage.

Proper bale handling and storage are crucial for safety, efficiency, and maintaining the quality of the baled materials:

- Safety: Bales should be handled with care to prevent injuries from falling or unstable bales.

- Efficiency: Proper storage ensures easy access to bales for transportation and recycling, maximizing productivity.

- Quality: Protecting bales from moisture, pests, and damage preserves their integrity and value.

5. Describe the safety precautions that must be observed when operating a baling machine.

- Proper Training: Operators must receive thorough training on the specific baling machine and its safety features.

- PPE: Safety gear such as gloves, safety glasses, and earplugs must be worn.

- Guarding: All moving parts and pinch points should be guarded to prevent contact injuries.

- Lockout/Tagout: Machines must be locked out and tagged out during maintenance or repairs.

- Clear Work Area: Keep the work area free from obstacles and tripping hazards.

- Emergency Stop: Operators must be familiar with the emergency stop button and its location.

6. How do you troubleshoot common baling machine problems?

- Bale Size Inconsistent: Check tension settings, material loading, and machine alignment.

- Machine Overheating: Inspect the hydraulic system for leaks, check oil levels, and ensure proper ventilation.

- Material Jams: Clear jammed material, adjust loading techniques, and check for any blockages in the baling chamber.

- Electrical Faults: Inspect wiring, connections, and electrical components, refer to the machine manual for specific troubleshooting steps.

- Hydraulic Leaks: Identify the source of the leak, tighten loose connections, or replace damaged components.

7. What is your approach to ensuring the quality of the bales produced?

- Proper Loading: Follow established loading procedures to prevent uneven or damaged bales.

- Machine Maintenance: Regularly inspect and maintain the baling machine to ensure optimal performance.

- Monitoring Process: Observe the baling process and make adjustments as needed to achieve consistent bale quality.

- Quality Control: Conduct regular inspections of the bales to ensure they meet the desired specifications.

8. How do you handle situations where the baling machine requires repair or maintenance?

- Safety First: Prioritize safety by following lockout/tagout procedures and wearing appropriate PPE.

- Troubleshooting: Attempt basic troubleshooting steps based on my knowledge and experience.

- Contact Supervisor: Inform my supervisor about the issue and follow their instructions.

- Coordinate with Maintenance Team: Work with the maintenance team to diagnose and resolve the problem efficiently.

- Documentation: Keep a record of the repair or maintenance performed for future reference.

9. How do you stay updated with the latest advancements in baling technology?

- Industry Publications: Subscribe to trade magazines and journals to stay informed about new technologies and best practices.

- Conferences and Trade Shows: Attend industry events to connect with experts and learn about the latest innovations.

- Online Research: Utilize online resources, websites, and forums to stay abreast of emerging technologies and industry trends.

- Manufacturer Training: Participate in training programs offered by baling machine manufacturers to gain knowledge about new features and advancements.

10. How do you work effectively as part of a team in a production environment?

- Communication: Maintain open communication with team members, supervisors, and clients to ensure smooth operations and resolve any issues promptly.

- Collaboration: Cooperate with colleagues to optimize production processes, share knowledge, and support each other during periods of high demand.

- Problem-Solving: Work with the team to identify and address production challenges, offering suggestions and implementing solutions collectively.

- Safety: Prioritize safety by adhering to established protocols, reporting any hazards, and actively participating in safety initiatives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Baling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Baling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Baling Machine Operators play a vital role in the recycling and waste management process. Their primary responsibility is to operate baling machines that compress recyclable materials into compact bales. These bales are then transported to recycling facilities for further processing and reuse.

1. Machine Operation and Maintenance

Operators are responsible for the safe and efficient operation of baling machines. They must be familiar with the machine’s controls and functions, and able to troubleshoot and resolve minor issues.

- Follow established procedures for loading, operating, and unloading baling machines

- Monitor machine performance and make adjustments as needed to ensure optimal bale quality

- Perform routine maintenance and cleaning tasks, including lubrication, filter replacement, and debris removal

2. Material Handling and Preparation

Operators must be able to handle and prepare recyclable materials for baling. This includes sorting materials, removing contaminants, and ensuring that the materials are properly sized and shaped for efficient baling.

- Identify and separate recyclable materials from non-recyclable waste

- Remove contaminants such as dirt, plastic, and metal from recyclable materials

- Cut or shred materials to appropriate size for baling

3. Bale Management

Operators are responsible for managing the bales produced by the machine. This includes stacking and storing bales safely and efficiently, and ensuring that bales meet quality standards.

- Stack and store bales securely to prevent damage or injury

- Label and track bales for inventory control and traceability

- Inspect bales for quality and reject any bales that do not meet specifications

4. Safety and Compliance

Operators must adhere to all safety protocols and regulations related to baling machine operation. They must also be aware of environmental regulations and best practices for waste management.

- Follow established safety procedures for operating baling machines and handling materials

- Wear appropriate personal protective equipment (PPE)

- Comply with all applicable environmental regulations and industry standards

Interview Tips

To ace your interview for a Baling Machine Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, values, and industry practices. This will enable you to demonstrate your interest and understanding during the interview.

- Visit the company’s website and social media pages

- Research industry trends and news

- Practice your answers to questions about your knowledge of the industry and the company

2. Highlight Relevant Experience

Emphasize your experience in operating baling machines and handling recyclable materials. Quantify your accomplishments and provide specific examples of your skills.

- Describe your previous experience operating baling machines, including the types of materials you handled

- Discuss your ability to identify and remove contaminants from recyclable materials

- Provide examples of your attention to detail and ability to ensure bale quality

3. Demonstrate Safety Awareness

Interviewers will want to know that you prioritize safety in the workplace. Highlight your understanding of safety protocols and your commitment to following them.

- Discuss your knowledge of safety procedures for operating baling machines and handling materials

- Emphasize your commitment to wearing appropriate PPE and adhering to established safety guidelines

- Share an example of a situation where you identified and resolved a safety hazard

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest. Prepare questions that demonstrate your curiosity about the role and the company.

- Inquire about the company’s sustainability goals and initiatives

- Ask about opportunities for professional development and advancement

- Seek information about the company’s safety record and training programs

Next Step:

Now that you’re armed with the knowledge of Baling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Baling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini