Are you gearing up for a career in Ball Mill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ball Mill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

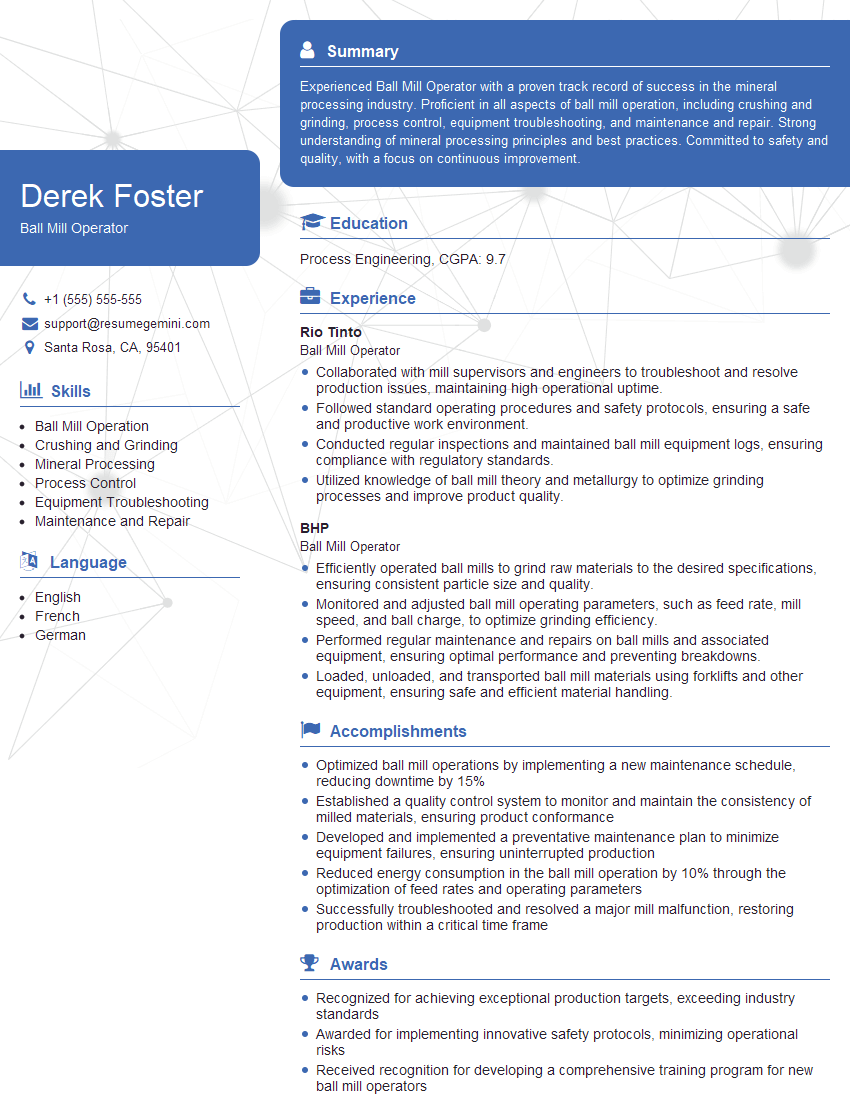

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ball Mill Operator

1. What is the purpose of a ball mill in mineral processing?

A ball mill is a cylindrical grinding device used in mineral processing to reduce the size of ore particles by impact and attrition. It consists of a cylindrical shell lined with wear-resistant material, containing a rotating assembly of steel balls or rods.

2. Describe the types of ball mills and their applications.

There are various types of ball mills, including:

- Batch ball mills: Used for small-scale operations or for specific grinding requirements. They are loaded with a batch of material, ground, and then unloaded.

- Continuous ball mills: Used for large-scale operations, where a continuous feed of material enters the mill and a continuous discharge of ground material exits. They are more efficient but require a larger capital investment.

- Rod mills: Similar to ball mills, but use rods instead of balls for grinding. They are more suitable for coarse grinding or when a finer product is not required.

3. How do you determine the optimal operating parameters for a ball mill?

The optimal operating parameters for a ball mill include:

- Ball size and charge: The size and quantity of balls or rods used can affect the grinding efficiency.

- Speed of rotation: The speed at which the mill rotates determines the impact forces and grinding action.

- Feed rate: The rate at which material is fed into the mill affects the residence time and grinding efficiency.

- Pulp density: The ratio of solids to liquid in the mill affects the grinding action and product size.

4. What are the common maintenance tasks associated with ball mills?

Common maintenance tasks include:

- Relining the shell: Replacing the wear-resistant lining as needed.

- Replacing balls or rods: Periodically replacing worn grinding media.

- Checking bearings and seals: Ensuring proper lubrication and sealing to prevent leaks.

- Inspecting and repairing electrical components: Maintaining the motor, drives, and control systems.

5. What are the safety precautions to observe when operating a ball mill?

Safety precautions include:

- Lockout/tagout procedures: Properly isolating and securing the mill before performing maintenance or repairs.

- Personal protective equipment: Wearing appropriate safety gear such as hard hats, safety glasses, and ear protection.

- Guarding: Ensuring all moving parts are properly guarded to prevent contact with personnel.

- Fire prevention: Avoiding flammable materials near the mill and having fire extinguishing equipment readily available.

6. Explain the role of grinding media in a ball mill and how to optimize their performance.

Grinding media, such as steel balls or rods, are crucial for the ball mill’s performance. To optimize their performance:

- Select the right type and size: Choose balls or rods based on the material being ground and the desired product size.

- Monitor wear and replacement: Regularly check ball or rod wear and replace them when necessary to maintain grinding efficiency.

- Optimize ball charge: Determine the optimal amount of grinding media to achieve the desired product size and minimize energy consumption.

7. Describe the different discharge methods used in ball mills and their advantages and disadvantages.

Ball mills can use different discharge methods, including:

- Gravity discharge: Material is discharged through an opening at the bottom of the mill, suitable for coarse grinding.

- Overflow discharge: Material is discharged through an overflow port, allowing for continuous operation and finer grinding.

- Grating discharge: A grating at the discharge end allows finer material to pass through while retaining larger particles for further grinding.

- Peripheral discharge: Material is discharged through openings around the mill’s periphery, enabling efficient grinding and removal of fine particles.

8. How do you troubleshoot common operational issues in ball mills?

Common operational issues and troubleshooting methods include:

- Low grinding efficiency: Check ball or rod wear, optimize ball charge, and adjust operating parameters.

- Excessive power consumption: Reduce ball charge, check for bearing problems, or adjust speed of rotation.

- Material contamination: Identify the source of contamination, clean the mill, and adjust grinding parameters.

- Overheating: Check bearing lubrication, reduce feed rate, or increase cooling.

9. Discuss the environmental considerations associated with ball mill operations and how to mitigate them.

Environmental considerations include:

- Dust emissions: Use dust collectors or enclosed systems to minimize dust release.

- Noise pollution: Install soundproofing or vibration dampening measures to reduce noise levels.

- Water usage: Optimize water usage in the grinding process and recycle or reuse process water.

- Energy consumption: Implement energy-efficient measures, such as variable speed drives or optimized operating parameters.

10. How do you stay updated with technological advancements in ball milling?

To stay updated with technological advancements, I:

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Engage with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ball Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ball Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ball Mill Operators hold significant responsibilities in operating and maintaining ball mills, essential equipment for grinding and reducing materials in various industries.

1. Operating Ball Mills

Their primary responsibility involves skillfully operating ball mills, ensuring efficient grinding processes by:

- Accurately feeding materials into the mills.

- Monitoring and adjusting mill settings to achieve desired particle size and consistency.

2. Maintenance and Inspection

To ensure smooth operation and prevent breakdowns, Ball Mill Operators must meticulously perform maintenance and inspection tasks:

- Regularly inspecting mills and identifying potential maintenance issues.

- Performing routine lubrication, cleaning, and minor repairs to maintain optimal equipment performance.

3. Product Quality Control

They play a crucial role in ensuring product quality by:

- Collecting and testing samples to monitor particle size distribution.

- Adjusting mill operating parameters to meet specified product specifications.

4. Safety and Compliance

Upholding safety protocols is paramount:

- Adhering to established safety procedures and wearing appropriate protective gear.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

Preparing for a Ball Mill Operator interview requires thorough research and effective communication skills. Here are some insightful tips to help you excel:

1. Research the Company and Industry

Acquiring knowledge about the company’s operations, products, and industry trends demonstrates your interest and enthusiasm.

- Visit the company’s website and gather information.

- Read industry-related publications and articles to stay informed.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and prior experience. Quantify your accomplishments whenever possible.

- Describe your experience operating and maintaining ball mills, providing specific examples.

- Discuss your problem-solving abilities and how you have handled equipment malfunctions.

3. Preparation for Technical Questions

Expect technical questions related to ball mill operation and maintenance. Prepare by reviewing fundamental concepts:

- Ball mill types, components, and operating principles.

- Factors influencing particle size and product quality.

4. Demonstrate Safety Awareness

Emphasize your commitment to safety by discussing your knowledge of safety protocols:

- Explain your understanding of safe work practices and emergency procedures.

- Provide examples of how you have ensured a safe work environment in previous roles.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ball Mill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.