Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ballast Cleaning Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

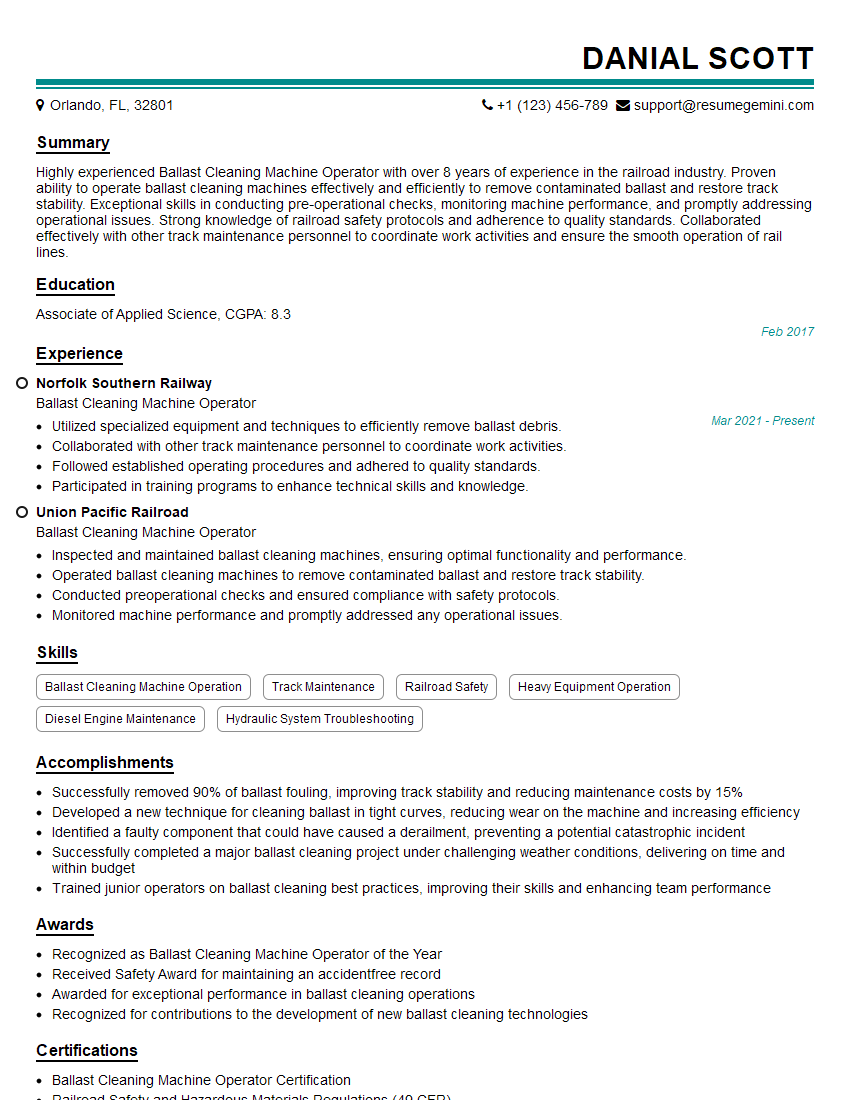

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ballast Cleaning Machine Operator

1. What are the key components of a ballast cleaning machine?

The key components of a ballast cleaning machine include:

- A hopper to hold the ballast

- A conveyor to move the ballast to the cleaning head

- A cleaning head to remove dirt and debris from the ballast

- A screening mechanism to remove fines from the ballast

- A discharge chute to distribute the cleaned ballast

2. What are the different types of ballast cleaning machines?

The different types of ballast cleaning machines include:

- On-track ballast cleaning machines

- Off-track ballast cleaning machines

- Mobile ballast cleaning machines

- Self-propelled ballast cleaning machines

3. What are the advantages of using a ballast cleaning machine?

The advantages of using a ballast cleaning machine include:

- Improved track safety and reliability

- Reduced track maintenance costs

- Improved track drainage

- Reduced environmental impact

4. What are the challenges of operating a ballast cleaning machine?

The challenges of operating a ballast cleaning machine include:

- The need for specialized training and experience

- The potential for accidents and injuries

- The environmental impact of the machine

- The cost of the machine and its operation

5. What are the safety precautions that must be taken when operating a ballast cleaning machine?

The safety precautions that must be taken when operating a ballast cleaning machine include:

- Wearing appropriate personal protective equipment

- Following all operating procedures

- Being aware of the machine’s surroundings

- Reporting any unsafe conditions or practices

6. What are the maintenance requirements for a ballast cleaning machine?

The maintenance requirements for a ballast cleaning machine include:

- Regular inspections

- Lubrication

- Adjustments

- Repairs

7. What are the troubleshooting procedures for a ballast cleaning machine?

The troubleshooting procedures for a ballast cleaning machine include:

- Identifying the problem

- Determining the cause of the problem

- Taking corrective action

- Verifying that the problem has been resolved

8. What are the latest developments in ballast cleaning technology?

The latest developments in ballast cleaning technology include:

- The use of GPS and other navigation systems to improve track cleaning accuracy

- The development of more efficient and environmentally friendly cleaning systems

- The use of remote monitoring and control systems to improve safety and productivity

9. What are the future trends in ballast cleaning?

The future trends in ballast cleaning include:

- The increased use of automated and autonomous machines

- The development of new and innovative cleaning technologies

- The increased focus on sustainability and environmental friendliness

10. What are the key skills and qualifications required to be a successful ballast cleaning machine operator?

The key skills and qualifications required to be a successful ballast cleaning machine operator include:

- A strong understanding of the principles of ballast cleaning

- Experience operating heavy machinery

- Excellent troubleshooting skills

- A commitment to safety

- A willingness to work long hours in a variety of weather conditions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ballast Cleaning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ballast Cleaning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ballast Cleaning Machine Operators are responsible for operating and maintaining ballast cleaning machines to remove debris and other contaminants from the ballast layer of railroad tracks. They play a crucial role in ensuring the safety and efficiency of rail operations by maintaining proper drainage and stability of the tracks.

1. Equipment Operation

Operate ballast cleaning machines effectively and efficiently to remove debris, fouled ballast, and other contaminants from the track bed.

2. Machine Maintenance

Perform routine maintenance and inspections on ballast cleaning machines, ensuring they are in good working order. Inspect and replace worn or damaged parts, lubricate components, and troubleshoot any mechanical issues.

3. Track Inspection

Inspect the tracks before and after cleaning operations to assess the condition of the ballast and identify any areas requiring additional attention.

4. Safety Compliance

Adhere to all safety regulations and procedures when operating ballast cleaning machines. Wear appropriate safety gear, follow established protocols, and maintain a clean and organized work environment.

Interview Tips

To ace the interview for a Ballast Cleaning Machine Operator position, it is essential to prepare thoroughly and showcase your relevant skills and experience.

1. Practice Common Interview Questions

Research common interview questions for this role and prepare thoughtful answers that highlight your qualifications. Practice delivering your responses clearly and confidently.

- Example Question: Tell us about your experience operating ballast cleaning machines.

- Example Answer: I have 5 years of experience operating ballast cleaning machines for a major railroad company. I am proficient in all aspects of machine operation, maintenance, and troubleshooting.

2. Emphasize Safety and Maintenance Skills

Ballast Cleaning Machine Operators must prioritize safety and ensure proper machine maintenance. Highlight your knowledge of safety regulations, your attention to detail, and your ability to quickly identify and resolve mechanical issues.

- Example Question: How do you ensure the safety of yourself and others while operating a ballast cleaning machine?

- Example Answer: I wear appropriate safety gear, follow all established protocols, and maintain a clean and organized work environment. I am also trained in emergency procedures and have a strong track record of maintaining a safe working environment.

3. Demonstrate Problem-Solving Abilities

Ballast Cleaning Machine Operators often encounter unexpected challenges during their work. Demonstrate your problem-solving skills by sharing examples of how you have identified and resolved issues while operating or maintaining ballast cleaning machines.

- Example Question: Describe a time when you encountered a mechanical issue with a ballast cleaning machine. How did you diagnose and resolve the problem?

- Example Answer: Once, during a cleaning operation, the machine experienced a sudden loss of power. I quickly checked the electrical connections, identified a loose wire, and reconnected it. This restored power to the machine, allowing me to continue the cleaning operation without significant delay.

4. Highlight Team Collaboration

Ballast Cleaning Machine Operators often work as part of a team. Emphasize your ability to collaborate effectively with others and contribute to a positive and productive work environment.

- Example Question: Describe a situation where you worked effectively as part of a team to complete a ballast cleaning project.

- Example Answer: In my previous role, I worked with a team of operators to clean a heavily fouled section of track. We coordinated our efforts, communicated regularly, and supported each other to ensure the project was completed safely and efficiently.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ballast Cleaning Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ballast Cleaning Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.