Feeling lost in a sea of interview questions? Landed that dream interview for Band Aid Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Band Aid Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

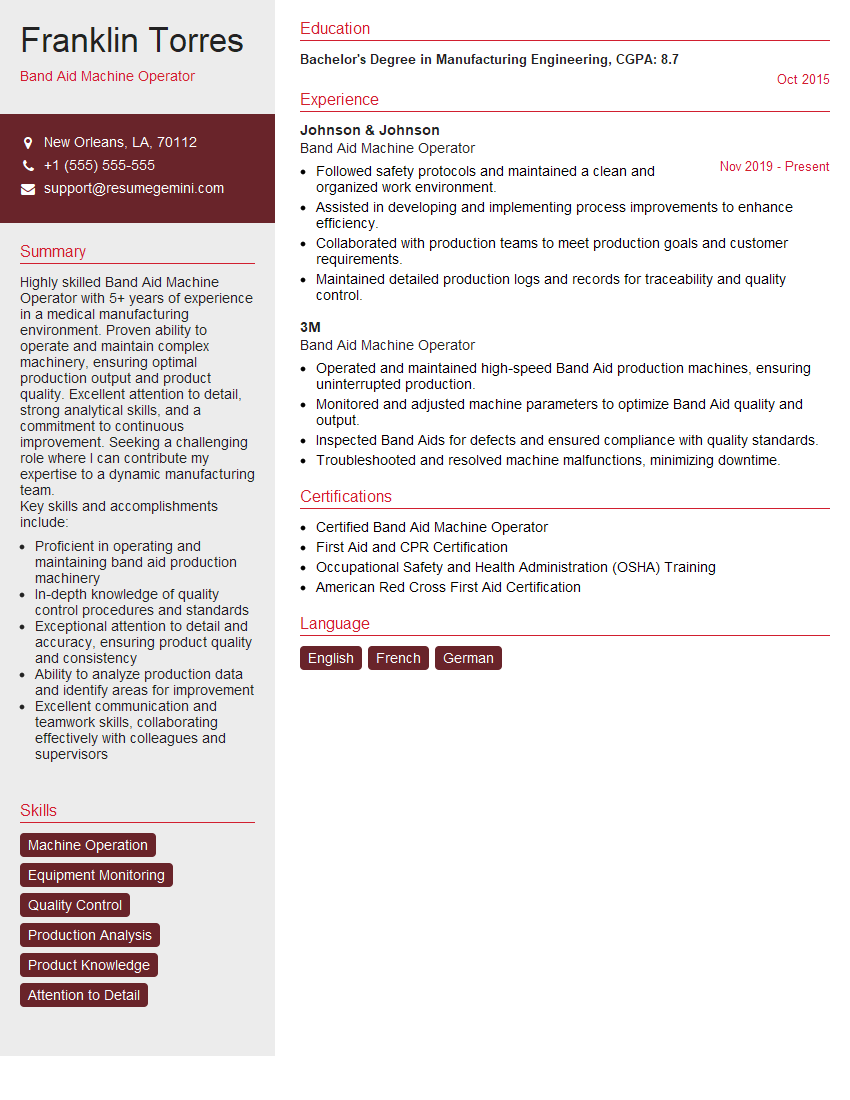

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Band Aid Machine Operator

1. Describe the process of setting up and operating a Band Aid machine.

- Inspect the machine for any damage or wear and tear.

- Load the backing material onto the machine.

- Place the adhesive onto the backing material.

- Cut the backing material into the desired shape and size.

- Apply the adhesive to the pad material.

- Place the pad material onto the backing material.

- Cut the pad material into the desired shape and size.

- Package the Band Aids.

2. What are the different types of Band Aid machines?

Manual Band Aid machines

- Require the operator to manually feed the materials into the machine.

- Less expensive than automatic machines.

- Slower than automatic machines.

Semi-automatic Band Aid machines

- Require the operator to manually load the backing material onto the machine, but the machine automatically feeds the adhesive and cuts the material.

- Faster than manual machines, but slower than automatic machines.

Automatic Band Aid machines

- Fully automated, requiring minimal operator intervention.

- Capable of producing large quantities of Band Aids quickly and efficiently.

3. What are the safety precautions that must be taken when operating a Band Aid machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions for safe operation.

4. What is the maintenance schedule for a Band Aid machine?

- Daily: Clean the machine and inspect it for any damage or wear and tear.

- Weekly: Lubricate the machine and check the tension of the belts.

- Monthly: Calibrate the machine and replace any worn or damaged parts.

- Annually: Have the machine serviced by a qualified technician.

5. What are the common problems that can occur with Band Aid machines?

- The machine may not be feeding the materials properly.

- The adhesive may not be applied evenly.

- The material may not be cut correctly.

- The machine may be making noise or vibrating excessively.

6. How do you troubleshoot a Band Aid machine?

- First, check to see if the machine is properly plugged in and turned on.

- Next, check to see if the materials are properly loaded into the machine.

- If the machine is still not working properly, consult the manufacturer’s instructions for troubleshooting.

7. What is the difference between a Band Aid and a bandage?

- Band Aids are small, adhesive dressings that are used to cover minor cuts and scrapes.

- Bandages are larger, non-adhesive dressings that are used to cover larger wounds.

8. What are the different types of Band Aids?

- There are many different types of Band Aids, including:

- Regular Band Aids

- Waterproof Band Aids

- Antibacterial Band Aids

- Character Band Aids

- Specialty Band Aids (e.g., for blisters or burns)

9. How do you choose the right Band Aid for a wound?

- The type of Band Aid you choose will depend on the size and location of the wound.

- For small, superficial wounds, a regular Band Aid will suffice.

- For larger or deeper wounds, a waterproof or antibacterial Band Aid may be necessary.

10. How do you apply a Band Aid?

- Clean the wound with soap and water.

- Dry the wound thoroughly.

- Apply the Band Aid to the wound, making sure that the adhesive side is facing down.

- Smooth the edges of the Band Aid to ensure that it is secure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Band Aid Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Band Aid Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities As a Band Aid Machine Operator, one plays a significant role in the production of Band-Aid bandages and related medical products. The core responsibilities include: – Operation and Maintenance of Band Aid Machines: – Accurately operate Band-Aid machines to manufacture adhesive bandages and other medical products. – Monitor and control machine settings, including speed, temperature, and tension. – Perform regular maintenance and troubleshooting to ensure efficient machine operation. – Product Quality Control: – Inspect produced Band-Aids for defects and ensure adherence to quality standards. – Conduct routine product testing to verify bandage adhesion, durability, and packaging integrity. – Identify and report any potential quality issues to supervisors. – Materials Management: – Manage the inventory of raw materials, including adhesive materials, gauze, and packaging components. – Ensure proper storage and handling of materials to prevent damage or contamination. – Monitor material usage and communicate any shortages or excesses to supervisors. – Production Monitoring and Reporting: – Track production output, monitoring machine performance and product quality. – Keep accurate records of production data, including machine downtime and product yield. – Share production reports with supervisors to support operational decision-making. – Compliance and Safety: – Adhere to all safety regulations and protocols while operating machinery and handling materials. – Maintain a clean and organized work area to prevent accidents and contamination. – Wear appropriate personal protective equipment (PPE) to minimize risks during operations. ## Interview Preparation Tips To excel in a Band Aid Machine Operator interview, consider the following preparation tips: ### 1. Research the Company and Role – Learn about the history, values, and industry prominence of the company. – Thoroughly review the job description and identify the essential responsibilities and qualifications. ### 2. Quantify Accomplishments – Provide concrete examples and data points to demonstrate your experience and results in previous roles. – Use STAR (Situation, Task, Action, Result) method to describe your achievements. – For instance, “In a previous role, I implemented a quality control system that reduced product defects by 30%.” ### 3. Highlight Relevant Skills – Emphasize your proficiency in operating and maintaining Band-Aid machines. – Showcase your understanding of adhesive materials and product specifications. – Highlight your attention to detail and commitment to producing high-quality products. ### 4. Prepare for Common Interview Questions – Practice answering common interview questions, such as: – “Describe your experience operating Band-Aid machines.” – “How do you ensure the quality of Band-Aid products?” – “What are your strengths and weaknesses as a Band Aid Machine Operator?” ### 5. Dress Appropriately – Choose professional attire that reflects the industrial setting and your commitment to safety. – Be punctual and arrive well-groomed to make a positive first impression. ### 6. Ask Thoughtful Questions – At the end of the interview, ask insightful questions to demonstrate your interest and engagement. – Inquire about the company’s quality standards, production processes, or career growth opportunities. ### 7. Obtain Feedback – After the interview, send a thank-you note to reiterate your interest and inquire about the next steps. – If you don’t get the job, politely request feedback to improve your future interviews.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Band Aid Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.