Are you gearing up for a career in Band Saw Filer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Band Saw Filer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

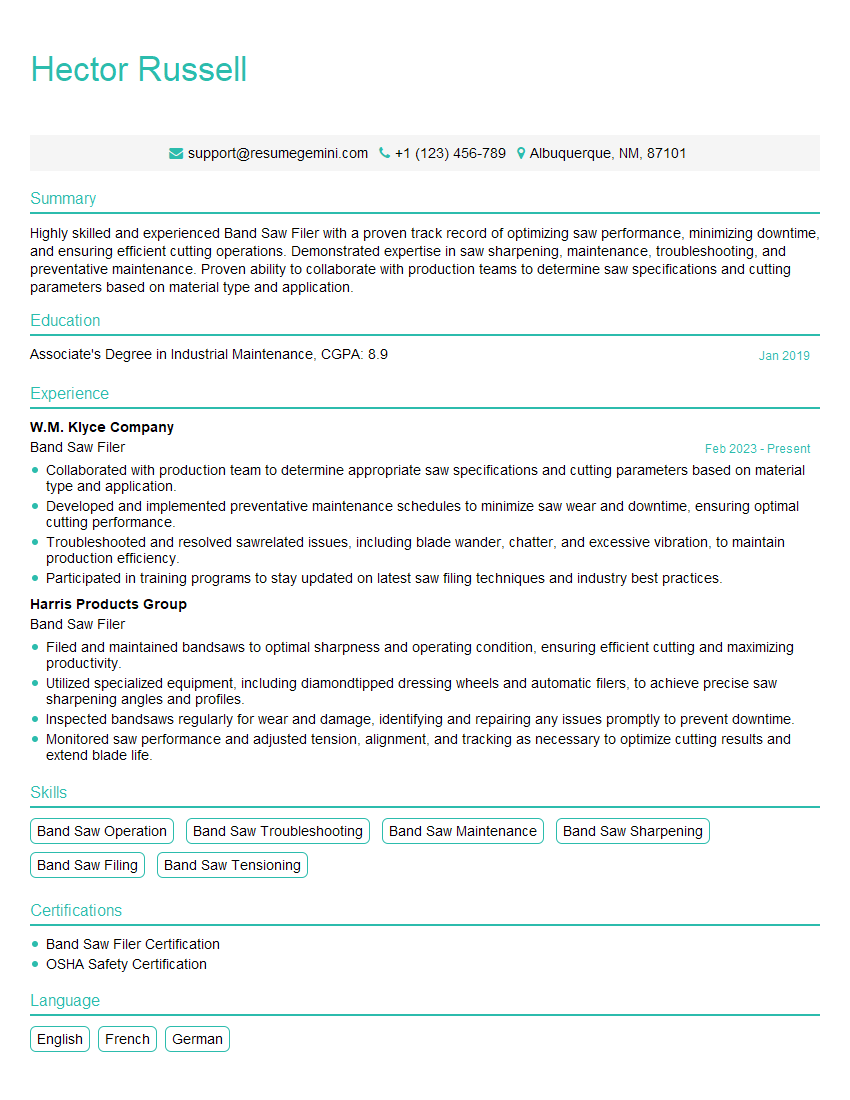

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Band Saw Filer

1. What are the different types of band saws used in the industry?

- Horizontal Band Saw

- Vertical Band Saw

- Contour Band Saw

- Portable Band Saw

2. Describe the process of brazing a band saw blade.

Brazing Process

- Clean and prepare the saw blade edges.

- Apply flux to the edges.

- Preheat the edges using a torch.

- Apply brazing alloy to the joint.

- Cool the brazed joint slowly.

Importance of Brazing

- Creates a strong and durable joint.

- Ensures proper blade tension and tracking.

- Prevents blade breakage and extends its lifespan.

3. How do you determine the correct tension for a band saw blade?

- Refer to the manufacturer’s specifications.

- Use a tensiometer to measure the tension.

- Consider the blade width and thickness.

- Adjust the tension according to the material being cut.

4. What are the common causes of band saw blade failure?

- Incorrect tension

- Poor blade alignment

- Overfeeding the material

- Dull or damaged blade

- Improper cooling

5. How do you troubleshoot a band saw that is not cutting properly?

- Inspect the blade for damage or dullness.

- Check the blade tension and alignment.

- Examine the guides and bearings for wear.

- Check the coolant system for proper lubrication.

- Consider the material being cut and adjust the cutting parameters accordingly.

6. What safety precautions should be taken when working with band saws?

- Wear appropriate PPE (safety glasses, gloves).

- Secure the material before cutting.

- Keep hands away from the cutting area.

- Use a push stick to feed the material.

- Never leave a running band saw unattended.

7. What are the recommended blade speeds for different materials?

The recommended blade speed varies depending on the material. Some examples are:

- Steel: 100-200 FPM

- Aluminum: 200-400 FPM

- Wood: 300-600 FPM

- Plastic: 400-800 FPM

8. How do you measure and adjust the pitch of a band saw blade?

- Measuring: Use a pitch gauge to determine the distance between teeth.

- Adjusting: Adjust the saw guide or tension to increase or decrease the pitch.

9. What are the advantages of using carbide-tipped band saw blades?

- Longer lifespan

- Faster cutting speeds

- Ability to cut harder materials

- Reduced downtime

10. How do you maintain and store band saw blades properly?

- Clean and lubricate blades after use.

- Store blades in a dry, controlled environment.

- Protect blades from impacts and damage.

- Inspect blades regularly for wear or damage.

- Follow manufacturer’s recommendations for sharpening and maintenance.

11. Can you describe different types of band saw guides and their applications?

- Plain Bearing Guides: Basic guides for general-purpose applications.

- Ball Bearing Guides: Reduce friction and improve blade stability.

- Curved Guides: Used for contour cutting and curved shapes.

- Ceramic Guides: Resistant to wear and heat, suitable for high-volume cutting.

- Air Bearing Guides: Offer exceptional accuracy and blade support through air pressure.

12. Explain the process of setting up and aligning a band saw for optimum performance.

- Install the blade and ensure proper tension.

- Align the wheels and guides to eliminate tracking issues.

- Adjust the blade guides to support the blade without restricting its movement.

- Calibrate the miter gauge for accurate angle cuts.

13. Discuss the importance of coolant in band sawing operations.

- Lubricates the blade to reduce friction and heat.

- Cools the blade to prevent overheating and blade failure.

- Washes away chips and swarf, improving cut quality.

- Extends blade lifespan by reducing wear and tear.

14. What factors influence the selection of the correct band saw blade for a specific application?

- Material to be cut: Different materials require specific blade types and specifications.

- Blade width and thickness: Impact cutting capacity and blade stability.

- Blade pitch: Determines the size and spacing of teeth, affecting cut quality and efficiency.

- Tooth set: Refers to the offset of each tooth to prevent binding and improve cutting performance.

- Band saw machine specifications: Blade size and type must be compatible with the machine.

15. How do you troubleshoot and resolve common band saw problems, such as blade vibration or deviation?

- Vibration: Check for loose components, unbalanced wheels, or improper blade tension.

- Deviation: Inspect guide alignment, blade tension, or the presence of obstacles in the cutting path.

- Blade breakage: Verify proper blade selection, tension, and cooling, or check for material defects.

- Premature blade wear: Consider blade sharpening, material hardness, or excessive cutting forces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Band Saw Filer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Band Saw Filer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Band Saw Filers, often working as part of a maintenance team in manufacturing industries, handle the installation, adjustment, and maintenance of band saws, ensuring optimal performance and efficiency of sawing operations. Their responsibilities include:

1. Band Saw Maintenance and Repair

The primary responsibility is to maintain band saws in proper working condition. This involves inspecting, cleaning, lubricating, and adjusting the saw’s components, such as the blade, guides, tensioning system, feed mechanism, and electrical systems. They also identify and repair any issues that may arise.

2. Installing and Aligning Band Saws

Band Saw Filers are responsible for installing and aligning band saws according to manufacturer specifications. They ensure that the saw is level, the blade is properly tensioned, and the guides are set correctly. They also make adjustments to optimize cutting performance and minimize blade wear.

3. Sharpening and Setting Band Saw Blades

Band Saw Filers sharpen and set band saw blades to maintain their cutting efficiency. They use specialized equipment to grind and shape the blade’s teeth, ensuring proper tooth geometry and angles. They also set the teeth to the correct pitch and gullet depth for the desired cutting application.

4. Troubleshooting and Problem-Solving

When issues arise with band saws, Band Saw Filers troubleshoot and diagnose the problem, identifying the root cause and implementing solutions. They analyze blade wear patterns, vibration issues, and other performance indicators to determine the underlying issues and make necessary repairs or adjustments.

Interview Preparation Tips for Band Saw Filers

To ace an interview for a Band Saw Filer position, candidates should prepare thoroughly and showcase their skills and experience in band saw maintenance and repair. Here are some helpful tips:

1. Research the company and position

Before the interview, candidates should research the company, its industry, and the specific role requirements. Understanding the company’s values, products or services, and industry trends demonstrates the candidate’s interest and preparation.

2. Practice common interview questions

Anticipate common interview questions related to band saw maintenance and repair. Prepare concise and clear answers that highlight your skills and experience. Examples include:

- Can you describe your experience in troubleshooting and repairing band saws?

- How do you ensure proper blade tension and alignment?

- What techniques do you use to sharpen and set band saw blades?

3. Emphasize safety procedures

Safety is paramount in band saw operation. Highlight your knowledge of safety protocols, including proper use of personal protective equipment, lockout/tagout procedures, and emergency response plans.

4. Showcase troubleshooting skills

Interviewers value problem-solving abilities. Provide examples of how you have diagnosed and resolved issues with band saws in the past. Describe your analytical approach and the steps you took to identify and correct the problems.

5. Prepare questions for the interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s band saw operation, maintenance practices, or any specific projects related to the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Band Saw Filer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!