Feeling lost in a sea of interview questions? Landed that dream interview for Band Sawing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Band Sawing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

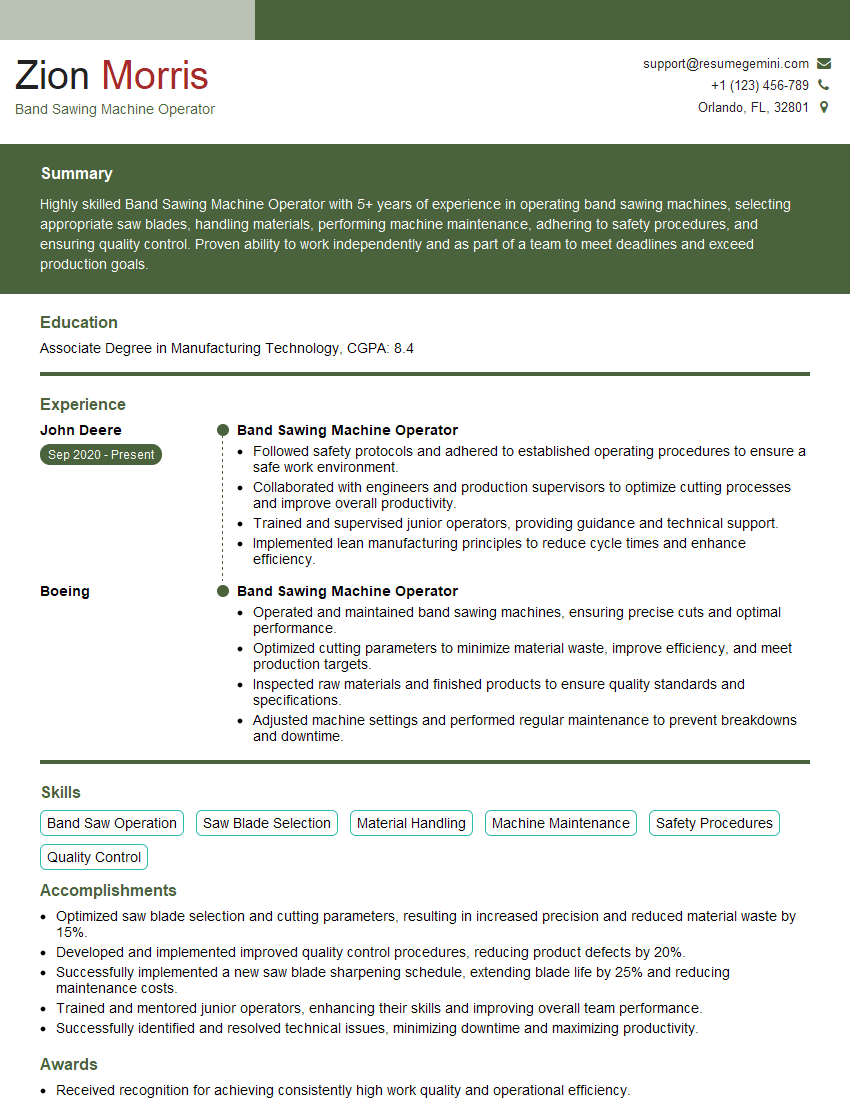

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Band Sawing Machine Operator

1. How do you ensure the accuracy of cuts made with a band sawing machine?

To ensure the accuracy of cuts, I follow these steps:

- Proper setup: Calibrate the machine and check the sharpness and alignment of the blade.

- Measuring and marking: Mark the workpiece precisely and measure twice before cutting.

- Stable workpiece: Secure the workpiece firmly using clamps or a vise to minimize movement.

- Guided cutting: Use a fence or miter guide to ensure the blade follows a straight or angled path.

- Smooth feeding: Feed the workpiece through the blade at a controlled pace to prevent binding or tearing.

- Regular maintenance: Keep the machine clean, lubricated, and properly adjusted to maintain its precision.

2. Explain how you determine the appropriate blade speed and tension for different materials.

To determine the appropriate blade speed and tension:

Blade speed

- High speeds for thin, soft materials like aluminum or plastic

- Lower speeds for thicker, harder materials like steel or cast iron

Blade tension

- Higher tension for thin blades or materials that tend to deflect

- Lower tension for thicker blades or materials that are more rigid

- Refer to manufacturer’s recommendations or consult with an experienced professional for specific settings.

3. What safety precautions should be taken when operating a band sawing machine?

To ensure safety when operating a band sawing machine, I adhere to the following precautions:

- Personal protective equipment: Safety glasses, gloves, and hearing protection are essential.

- Machine guarding: Keep guards in place and ensure they are functioning properly.

- Blade inspection: Regularly inspect the blade for damage or defects and replace it if necessary.

- Secure workpiece: Clamp or secure the workpiece firmly to prevent it from moving during cutting.

- Proper feeding technique: Feed the workpiece at a controlled pace and avoid exerting excessive force.

- Stay alert and focused: Pay attention to the machine and the material being cut, especially when making complex cuts.

4. How do you resolve common issues such as blade breakage or material binding?

To resolve common issues:

Blade breakage

- Check for dull or damaged blades and replace if necessary.

- Adjust blade tension and speed to appropriate settings.

- Ensure workpiece is properly secured and stable.

Material binding

- Reduce feeding pressure and ensure the blade is cutting freely.

- Check for buildup on the workpiece or blade and clean or lubricate as needed.

- Adjust blade speed and tension to optimize cutting efficiency.

5. How do you calculate the material yield for a given project?

To calculate material yield:

- Determine the volume of the material being used (length x width x height).

- Calculate the volume of material needed for the project (length x width x height).

- Divide the volume of material needed by the volume of material being used to get the material yield.

- Consider factors such as cutting loss and kerf width in the calculation.

6. Explain the difference between a horizontal and a vertical band sawing machine.

The main difference between a horizontal and a vertical band sawing machine lies in the orientation of the blade:

Horizontal band sawing machine

- Blade is oriented horizontally

- Suitable for cutting large or heavy materials

- Allows for easier handling of bulky workpieces

Vertical band sawing machine

- Blade is oriented vertically

- Designed for precision cutting of smaller workpieces

- Supports accurate cutting of shapes, angles, and curves

7. How do you optimize the efficiency of a band sawing machine operation?

To optimize efficiency:

- Proper blade selection: Choose the appropriate blade type and tooth geometry for the material being cut.

- Sharp blades: Use sharp blades to reduce cutting resistance and improve efficiency.

- Controlled feeding: Feed the workpiece at an optimal pace to avoid binding or excessive force.

- Coolant use: Utilize coolant to reduce friction and extend blade life.

- Regular maintenance: Regularly clean, lubricate, and inspect the machine to maintain its performance.

8. Describe the different types of cuts that can be made with a band sawing machine.

A band sawing machine can make various types of cuts:

- Straight cuts: Cutting a workpiece along a straight line

- Angled cuts: Cutting a workpiece at a specific angle, using a miter guide

- Contour cuts: Cutting along a curved or irregular shape, using a template or freehand technique

- Nested cuts: Cutting multiple pieces from a single workpiece, optimizing material usage

- Compound cuts: Combinations of multiple types of cuts, such as angled and contour cuts

9. How do you ensure that the band sawing machine is calibrated and operating accurately?

Calibration and accuracy are crucial:

- Regular inspection: Visually inspect the machine for any damage or misalignment.

- Blade alignment: Adjust the blade guides to ensure proper alignment and prevent wandering.

- Fence alignment: Check and adjust the fence to ensure perpendicularity to the blade and the cutting table.

- Calibration tools: Use measuring tools and gauges to calibrate the machine and verify its accuracy.

- Test cuts: Perform test cuts on scrap material to confirm the machine’s precision and make any necessary adjustments.

10. What are the common maintenance tasks required for a band sawing machine?

Regular maintenance is essential:

- Cleaning: Clean the machine regularly to remove dust, debris, and coolant buildup.

- Lubrication: Lubricate moving parts to reduce friction and wear.

- Blade inspection: Inspect the blade for damage or dullness and replace it when necessary.

- Guide adjustment: Adjust the blade guides to ensure proper alignment and prevent premature blade wear.

- Tension adjustment: Check and adjust the blade tension to optimize cutting performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Band Sawing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Band Sawing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Band Sawing Machine Operators are responsible for the safe and efficient operation of band sawing machines. They must have a good understanding of the machine’s operation and capabilities, as well as the ability to read and interpret blueprints and instructions.

1. Set up and operate band sawing machines

This involves selecting the correct blade, setting the machine to the proper speed and feed rate, and loading the material to be cut.

- Select the correct blade for the material to be cut.

- Set the machine to the proper speed and feed rate.

- Load the material to be cut.

- Operate the machine safely and efficiently.

2. Inspect and maintain band sawing machines

This includes checking the machine for any signs of damage or wear, and cleaning and lubricating it as necessary.

- Check the machine for any signs of damage or wear.

- Clean and lubricate the machine as necessary.

- Replace worn or damaged parts.

- Troubleshoot and repair minor problems.

3. Follow safety procedures

This includes wearing the proper safety gear, following lockout/tagout procedures, and keeping the work area clean and free of debris.

- Wear the proper safety gear.

- Follow lockout/tagout procedures.

- Keep the work area clean and free of debris.

- Report any unsafe conditions to the supervisor.

4. Maintain records

This includes keeping track of the number of parts produced, the amount of material used, and any downtime.

- Keep track of the number of parts produced.

- Keep track of the amount of material used.

- Keep track of any downtime.

- Report any production problems to the supervisor.

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to help yourself ace the interview and land the job you want.

1. Research the company and the position

This will help you understand the company’s culture, values, and what they are looking for in a candidate. You can research the company’s website, social media pages, and news articles.

- Visit the company’s website.

- Follow the company on social media.

- Read news articles about the company.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Prepare answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend or family member.

- Use the STAR method to answer interview questions.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear clean, pressed clothes.

- Dress appropriately for the office environment.

- Avoid wearing revealing or too casual clothing.

- Make sure your clothes are comfortable so that you can focus on the interview.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route in advance.

- Leave early to allow for traffic or other unexpected delays.

- If you are running late, call the interviewer to let them know.

- Arrive at the interview location a few minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Band Sawing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.