Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bandmill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

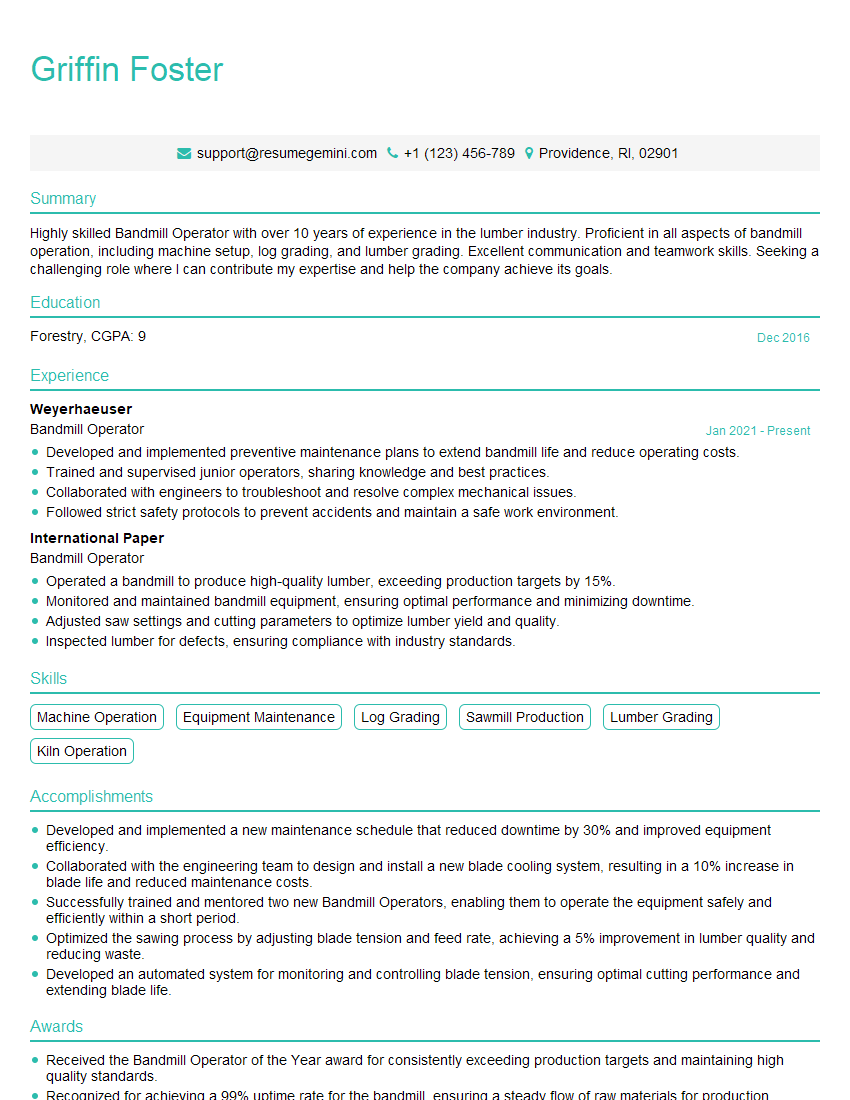

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bandmill Operator

1. Describe the key responsibilities of a Bandmill Operator

As a Bandmill Operator, I would be responsible for the safe and efficient operation of the bandmill, ensuring that it produces high-quality products while adhering to safety protocols. My primary tasks would include:

- Loading logs onto the bandmill and positioning them for cutting

- Monitoring the cutting process, adjusting saw blade tension and feed rate to optimize cut quality

- Inspecting the cut lumber for defects and removing any substandard pieces

- Maintaining and calibrating the bandmill to ensure its continued accuracy and precision

- Following established safety procedures, wearing appropriate personal protective equipment, and maintaining a clean and organized work area

2. How do you ensure the optimal cutting performance of a bandmill?

Blade Maintenance and Tension

- Regularly inspect the saw blade for sharpness and wear, replacing it when necessary

- Maintain proper blade tension to prevent breakage and ensure accurate cutting

Log Preparation and Positioning

- Ensure that logs are free of knots, defects, and foreign objects that could damage the blade

- Position logs on the carriage securely and align them properly to achieve desired cut dimensions

Cutting Parameters

- Adjust the feed rate and blade speed based on the log’s size, species, and desired cutting pattern

- Monitor the cutting process and make adjustments as needed to maintain optimal cut quality

3. What are the common defects that can occur in bandmilled lumber and how do you identify them?

Common defects in bandmilled lumber include:

- Splits and Cracks: Longitudinal or transverse separations in the wood, caused by stress or improper drying

- Knots: Irregularities in the grain pattern caused by branches, which can reduce strength and stability

- Wane: Bark or rounded edges remaining on the lumber, usually caused by improper log debarking or sawing

- Warp: Distortion in the lumber’s shape, such as bowing, twisting, or cupping, due to uneven drying or stress

- Checks: Surface cracks perpendicular to the grain, caused by shrinkage during drying or exposure to extreme temperatures

To identify these defects, I would visually inspect the lumber, paying attention to its appearance, texture, and any irregularities.

4. Describe the safety protocols that you follow while operating a bandmill

- Always wear appropriate personal protective equipment, including safety glasses, earplugs, gloves, and a hard hat

- Ensure that the bandmill is properly grounded and that all guards and safety devices are in place and functioning

- Inspect the saw blade and carriage regularly for any damage or wear, and replace or repair as needed

- Never operate the bandmill under the influence of drugs or alcohol

- Be aware of the location of the emergency stop button and know how to use it in case of an emergency

- Keep the work area clean and free of debris to prevent slips, trips, or falls

5. How do you troubleshoot common problems that can occur with a bandmill?

- Blade Breakage: Check blade tension, inspect for damage, and ensure proper alignment

- Poor Cut Quality: Adjust blade speed, feed rate, or saw blade sharpness

- Vibration: Check for loose components, unbalanced blade, or improper log positioning

- Motor Overheating: Check for electrical faults, excessive load, or inadequate ventilation

- Hydraulic Leaks: Inspect hoses, fittings, and cylinders for damage or wear

I would use my knowledge of the bandmill’s mechanical and electrical systems to identify and resolve these issues efficiently.

6. What is your experience with optimizing lumber yield from logs?

To optimize lumber yield, I would:

- Select logs with minimal defects and appropriate dimensions for the desired products

- Position logs on the carriage to maximize the number of clear, straight cuts

- Adjust the cutting pattern to minimize waste and produce the most valuable lumber grades

- Monitor the cutting process and make adjustments as needed to ensure maximum lumber recovery

- Properly stack and store lumber to prevent damage and maintain its value

7. Can you explain the process of saw blade maintenance and sharpening?

Saw blade maintenance and sharpening are crucial for maintaining optimal bandmill performance. My process includes:

Maintenance

- Regularly inspect the blade for wear, damage, or cracks

- Clean the blade to remove sawdust, pitch, and other debris

- Check blade tension and adjust as needed to prevent breakage

Sharpening

- Use a specialized saw blade sharpener to grind and shape the teeth

- Maintain the proper tooth angle and profile for the desired cutting application

- Check the sharpness of the blade using a test cut or visual inspection

8. Describe how you would handle a situation where you encounter a problem with the bandmill that you cannot resolve yourself

- First, I would assess the situation and try to identify the root cause of the problem

- If I am unable to resolve the issue, I would immediately notify my supervisor or a qualified technician

- I would provide a clear description of the problem, including any error messages or observations

- I would assist the technician in troubleshooting and resolving the issue as needed

9. What are your goals for this role as a Bandmill Operator?

- To contribute my skills and experience to the efficient and safe operation of the bandmill

- To continuously improve my knowledge and understanding of bandmill operations

- To work effectively as part of a team to optimize lumber production and quality

- To maintain a clean and organized work environment, adhering to all safety protocols

- To advance my career in the lumber industry and contribute to the success of the company

10. Do you have any questions for me about the role or the company?

This is an opportunity for you to ask questions and demonstrate your interest in the position and the company. Here are some examples:

- What is the company’s commitment to safety and environmental sustainability?

- Can you provide more information about the career advancement opportunities within the company?

- What are the company’s expectations for the Bandmill Operator role in terms of productivity and quality standards?

- What is the company’s policy on training and professional development for employees?

- Can you give me an overview of the company’s current projects and future growth plans?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bandmill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bandmill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bandmill Operator is responsible for the operation and maintenance of a bandmill, a machine used to saw logs into lumber.

1. Operating the Bandmill

The Bandmill Operator is responsible for the safe and efficient operation of the bandmill. This includes:

- Loading logs onto the bandmill

- Adjusting the bandmill settings to ensure the correct thickness and width of the lumber

- Monitoring the bandmill for any problems and taking corrective action as needed

2. Maintaining the Bandmill

The Bandmill Operator is also responsible for the maintenance of the bandmill. This includes:

- Keeping the bandmill clean and free of debris

- Inspecting the bandmill for any worn or damaged parts and replacing them as needed

- Lubricating the bandmill according to the manufacturer’s instructions

3. Quality Control

The Bandmill Operator is responsible for the quality of the lumber produced by the bandmill. This includes:

- Inspecting the lumber for any defects

- Sorting the lumber by grade

- Rejecting any lumber that does not meet the required specifications

4. Safety

The Bandmill Operator is responsible for the safety of themselves and others in the workplace. This includes:

- Following all safety procedures

- Wearing appropriate safety gear

- Reporting any unsafe conditions to the supervisor

Interview Tips

Here are some tips to help you ace your interview for a Bandmill Operator position:

1. Research the position and the company

Before you go to the interview, be sure to research the position and the company. This will give you a good understanding of the job requirements and the company culture. You can find information about the position on the company’s website or by talking to someone in the Human Resources department.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

Be sure to highlight your experience and skills that are relevant to the Bandmill Operator position. For example, you might want to talk about your experience operating bandmills, your knowledge of lumber grading, or your safety record. If you have any certifications or training that is relevant to the position, be sure to mention those as well.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive. Be sure to show your passion for the Bandmill Operator position and your eagerness to learn and grow. A positive attitude will make you a more attractive candidate.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are eager to learn more. You can send a thank-you note to the interviewer, or you can call or email to ask about the status of your application. Following up will help you stay on the interviewer’s mind and increase your chances of getting the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bandmill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!