Are you gearing up for an interview for a Bandsaw Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bandsaw Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

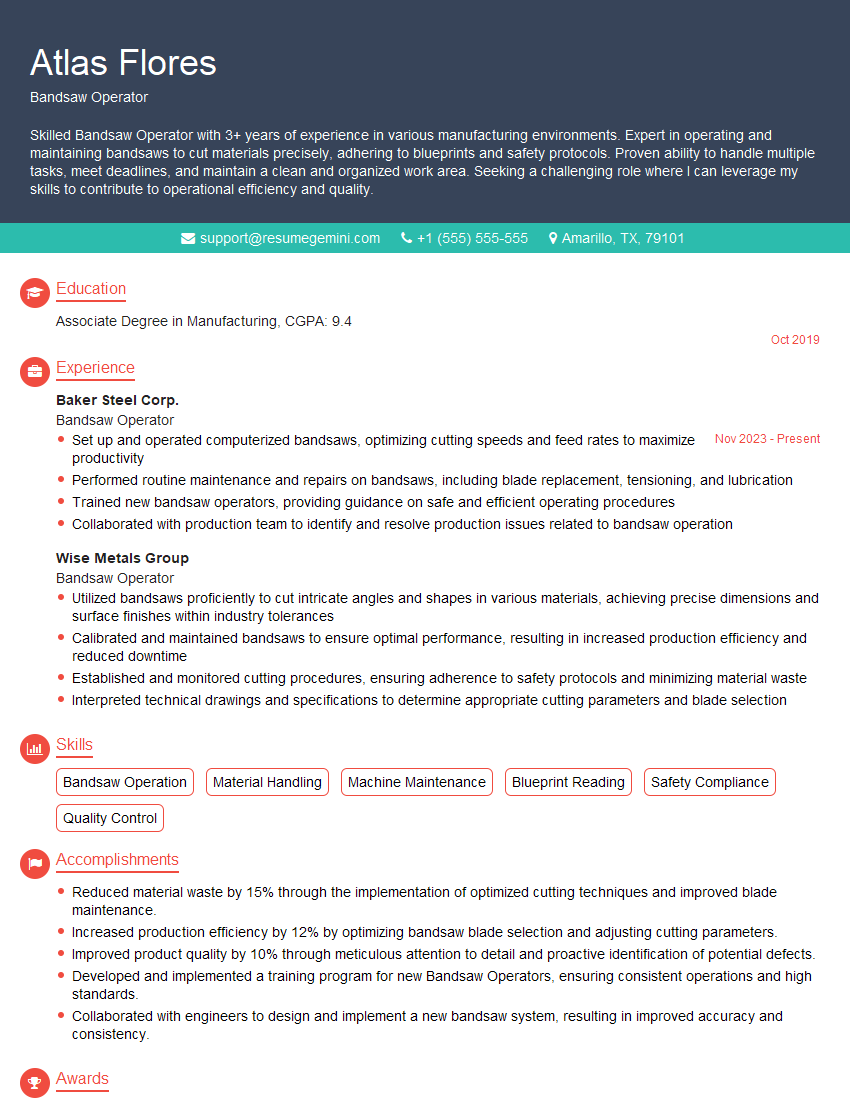

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bandsaw Operator

1. How would you maintain and adjust the tension of the bandsaw blade to ensure optimal cutting performance?

- Use a tension meter to measure the blade tension and adjust it to the manufacturer’s specifications.

- Check the blade for any cracks, breaks, or damage, and replace it if necessary.

- Clean and lubricate the blade guides and bearings to minimize friction and wear.

2. What are the different types of blades used in bandsaws, and how do you select the appropriate blade for a specific cutting application?

Blade Types

- Carbon steel blades: Hard and durable, suitable for cutting ferrous metals.

- Bimetal blades: Combination of carbon steel and high-speed steel, offering a balance of strength and hardness.

- High-speed steel blades: Made of alloy steel, used for cutting hard materials like stainless steel.

Blade Selection

- Consider the material being cut and its thickness.

- Determine the desired cut quality (smoothness, precision).

- Refer to the manufacturer’s specifications for blade recommendations.

3. Describe the steps involved in setting up a bandsaw for a specific cutting operation, including blade selection, workpiece clamping, and safety precautions.

- Select and install the appropriate blade for the material and cutting requirements.

- Securely clamp the workpiece to the worktable, ensuring it is properly aligned with the blade.

- Adjust the blade tension and tracking to optimize cutting performance.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves.

4. How would you troubleshoot common problems encountered while operating a bandsaw, such as blade breakage, misalignment, or excessive vibration?

- Blade Breakage: Check for tension issues, damaged blades, or improper material selection.

- Misalignment: Adjust the blade guides, bearings, or pulleys to ensure proper alignment.

- Excessive Vibration: Tighten loose components, check for balance issues in the blade or machine, or adjust the blade tension.

5. What are the safety protocols and best practices for operating a bandsaw in a production environment?

- Follow all manufacturer’s safety instructions.

- Wear appropriate PPE, including eye, hearing, and hand protection.

- Ensure the machine is properly grounded and isolated during maintenance.

- Keep the work area clean and free of tripping hazards.

- Report any safety concerns or malfunctions immediately to a supervisor.

6. How do you calculate the cutting speed and feed rate for a given cutting operation on a bandsaw?

- Cutting Speed: Use the formula: Cutting Speed = (Blade Diameter * Pi * RPM) / 12

- Feed Rate: Determine the appropriate feed rate based on the material, blade type, and desired cut quality.

7. What are the different types of cuts that can be made with a bandsaw, and how do you adjust the machine’s parameters to achieve them?

- Straight Cut: Use a straight blade and standard feed rate.

- Angle Cut: Adjust the miter gauge to the desired angle.

- Contour Cut: Use a contouring blade and slow feed rate to follow the desired shape.

8. How do you ensure the accuracy and precision of cuts made on a bandsaw?

- Use sharp, high-quality blades.

- Maintain the machine regularly to minimize play or backlash.

- Securely clamp the workpiece to prevent movement during cutting.

- Set the cutting speed and feed rate appropriately.

9. How do you maintain a bandsaw to ensure optimal performance and longevity?

- Clean the machine regularly to remove dust and debris.

- Lubricate moving parts as per the manufacturer’s specifications.

- Replace worn or damaged components, such as belts, blades, and bearings.

- Perform regular safety checks to ensure the machine is operating safely.

10. What are the potential hazards associated with operating a bandsaw, and how do you minimize them?

- Blade Contact: Wear safety gloves and avoid coming into contact with the blade while it is running.

- Kickback: Ensure the workpiece is securely clamped to prevent kickback.

- Flying Chips: Wear eye protection to prevent injuries from flying chips.

- Electrical Hazards: Ensure the machine is properly grounded and isolated during maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bandsaw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bandsaw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bandsaw Operators control and operate bandsaws to cut various materials in a mill or manufacturing environment.

1. Material Handling

Bandsaw Operators are responsible for handling and loading materials onto the bandsaw.

- Position workpieces on the receiving table and align it with the blade guide.

- Securely fasten workpieces to prevent shifting or movement during cutting.

2. Machine Operation

Bandsaw Operators operate the bandsaw machine and monitor its performance while cutting materials.

- Operate the bandsaw and control its speed, feed rate, and blade tension.

- Make adjustments to the machine settings to ensure optimal cutting results.

3. Dimension Measurement and Inspection

Bandsaw Operators measure and inspect cut materials to ensure they meet specifications.

- Verify the dimensions and quality of cut pieces using measuring tools like rulers, calipers, and gauges.

- Identify and correct any deviations or defects in the cut materials.

4. Maintenance and Troubleshooting

Bandsaw Operators perform basic maintenance and troubleshooting on bandsaw machines to ensure smooth operation.

- Clean and lubricate the bandsaw machine’s components regularly.

- Inspect and replace worn or damaged parts as needed.

Interview Tips

Proper preparation is key to acing any job interview, and the interview for a Bandsaw Operator position is no exception. Here are a few tips to help you make a great impression and increase your chances of landing the job:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific Bandsaw Operator role you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website to learn about their business, products or services, and company culture.

- Read online reviews from current or former employees to get insights into the work environment and company culture.

- Carefully review the job description and identify the key skills, experience, and qualifications required for the role.

2. Practice Answering Common Interview Questions

There are certain common interview questions that you are likely to be asked during an interview for a Bandsaw Operator position. Prepare for these questions by practicing your answers beforehand.

- Tell me about your experience operating bandsaw machines.

- Describe your knowledge of bandsaw machine maintenance and troubleshooting.

- How do you ensure the accuracy and quality of cut materials?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Bandsaw Operator role.

- Emphasize your experience operating bandsaw machines, including the types of materials you have cut and the accuracy you have achieved.

- Describe your knowledge of bandsaw machine maintenance and troubleshooting, and provide examples of how you have resolved common issues.

- Explain your quality control procedures and how you ensure the accuracy and quality of cut materials.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you are interested in the job and that you are excited about the opportunity to work for the company.

- Make eye contact with the interviewer and smile when appropriate.

- Speak clearly and confidently, and be respectful of the interviewer’s time.

- Thank the interviewer for their time and consideration at the end of the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bandsaw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!