Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Barbed Wire Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

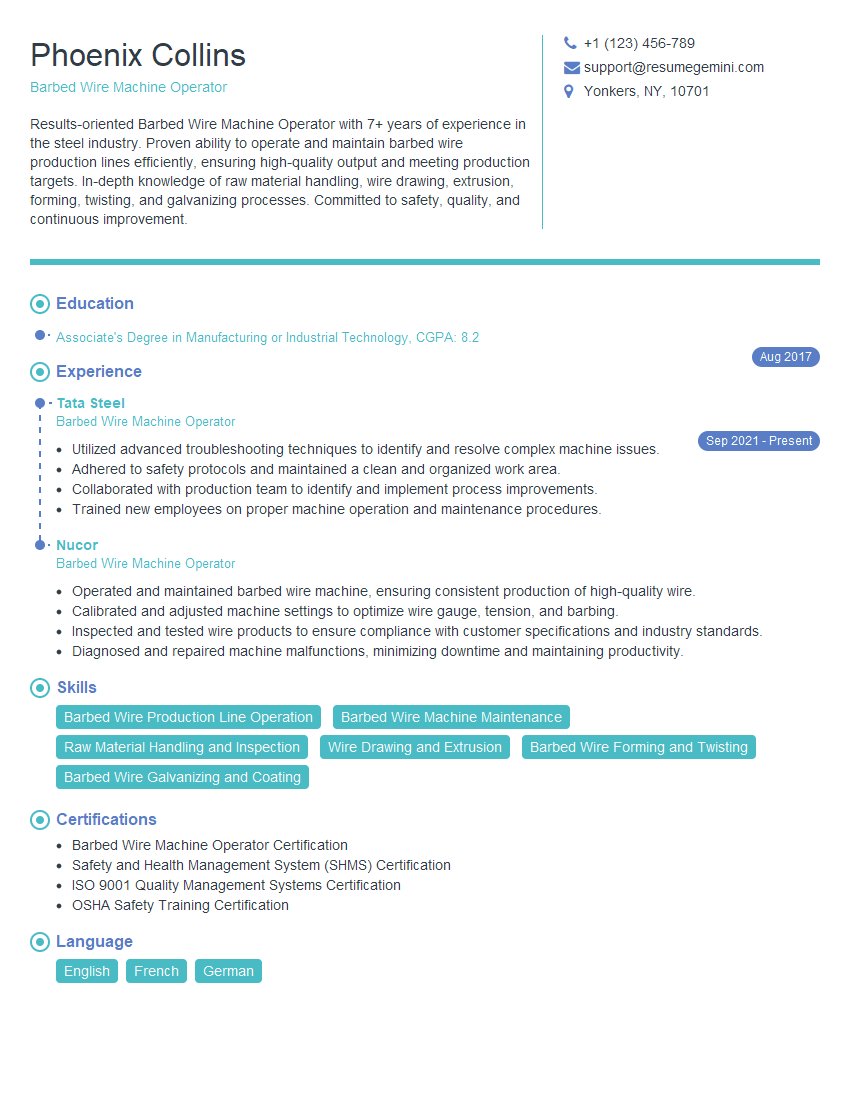

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barbed Wire Machine Operator

1. How do you calculate the amount of barbed wire needed for a given perimeter?

To calculate the amount of barbed wire needed, you need to know the perimeter of the area that you want to enclose. Once you have the perimeter, you can use the following formula:

Amount of barbed wire needed = Perimeter length + 10% (for waste)

For example, if the perimeter of the area is 100 meters, then you would need 110 meters of barbed wire.

2. What are the different types of barbed wire and their uses?

Types of Barbed Wire:

- Single-strand barbed wire: This is the most common type of barbed wire and is made of a single strand of steel wire with sharp barbs. It is used for fencing pastures, fields, and other areas.

- Double-strand barbed wire: This type of barbed wire has two strands of steel wire twisted together with sharp barbs on both strands. It is stronger than single-strand barbed wire and is used for fencing areas that need more security.

- Triple-strand barbed wire: This type of barbed wire has three strands of steel wire twisted together with sharp barbs on all three strands. It is the strongest type of barbed wire and is used for fencing areas that need maximum security.

3. How do you install barbed wire fencing?

To install barbed wire fencing, you will need the following materials:

– Barbed wire

– Fence posts

– Wire stretcher

– Wire cutters

– Staples or nails

Steps for Installing Barbed Wire Fencing

1. Determine the perimeter of the area that you want to fence.

2. Set the fence posts in the ground. The posts should be spaced 8-10 feet apart.

3. Run the barbed wire through the wire stretcher.

4. Stretch the barbed wire between the fence posts.

5. Staple or nail the barbed wire to the fence posts.

6. Cut the barbed wire and remove the wire stretcher.

4. What are the safety precautions that you need to take when working with barbed wire?

- Wear gloves and eye protection.

- Be aware of your surroundings and watch for hazards.

- Do not work with barbed wire in wet or windy conditions.

- Do not attempt to repair barbed wire that is damaged.

- If you are injured by barbed wire, seek medical attention immediately.

5. What are the different types of machines used to produce barbed wire?

- Single-strand barbed wire machine: This type of machine produces single-strand barbed wire by twisting a single strand of steel wire around a series of sharp barbs.

- Double-strand barbed wire machine: This type of machine produces double-strand barbed wire by twisting two strands of steel wire together around a series of sharp barbs.

- Triple-strand barbed wire machine: This type of machine produces triple-strand barbed wire by twisting three strands of steel wire together around a series of sharp barbs.

6. How do you maintain a barbed wire machine?

- Clean the machine regularly to remove any dirt or debris.

- Lubricate the machine regularly to keep it running smoothly.

- Inspect the machine regularly for any signs of damage.

- Repair or replace any damaged parts as soon as possible.

7. What are the different types of materials used to make barbed wire?

- Steel: Steel is the most common material used to make barbed wire. It is strong and durable, and it can be coated with a variety of materials to protect it from rust and corrosion.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is sometimes used to make barbed wire. It is not as strong as steel, but it is less likely to rust.

- Stainless steel: Stainless steel is a strong and corrosion-resistant material that is sometimes used to make barbed wire. It is more expensive than steel, but it is less likely to rust.

8. What are the different factors that affect the cost of barbed wire?

- The type of material used to make the barbed wire

- The gauge of the wire

- The length of the roll of barbed wire

- The number of barbs per foot

- The type of coating on the barbed wire

9. What are the environmental impacts of barbed wire?

- Barbed wire can injure animals and birds.

- Barbed wire can damage vegetation.

- Barbed wire can pollute the environment if it is not properly disposed of.

10. What are the different applications for barbed wire?

- Fencing pastures, fields, and other areas

- Protecting crops from animals

- Creating security barriers

- Decorating fences and gates

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barbed Wire Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barbed Wire Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barbed Wire Machine Operators are responsible for operating and maintaining barbed wire making machines in a manufacturing setting. They ensure the smooth and efficient production of barbed wire, which is used for a wide range of purposes such as fencing, security, and agriculture.

1. Machine Operation

Operate and maintain barbed wire making machines to produce barbed wire of various specifications.

- Set up and calibrate machines according to production requirements.

- Monitor machine performance, identify malfunctions, and take corrective actions to prevent breakdowns.

2. Quality Control

Conduct regular quality checks on barbed wire to ensure it meets the required specifications.

- Inspect wire for any defects or irregularities.

- Record production data and maintain quality control records.

3. Maintenance and Repairs

Perform basic maintenance and repairs on machines to keep them in optimal working condition.

- Lubricate, clean, and adjust machines as needed.

- Replace worn or damaged parts to prevent machine failures.

4. Safety and Compliance

Follow safety protocols and maintain a clean and organized work area.

- Wear appropriate personal protective equipment (PPE) and adhere to safety regulations.

- Ensure compliance with environmental and regulatory standards.

Interview Tips

Preparing for an interview for a Barbed Wire Machine Operator position requires thorough understanding of the role and its responsibilities, as well as a well-rounded approach to showcasing your skills and experience.

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and the specific requirements of the Barbed Wire Machine Operator role.

- Visit the company’s website and LinkedIn page.

- Review the job description thoroughly.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining barbed wire making machines.

- Showcase your knowledge of machine setup, calibration, and troubleshooting.

- Highlight your experience in quality control and maintaining production standards.

3. Demonstrate Safety Awareness

Stress your commitment to safety and compliance.

- Explain your understanding of safety protocols and PPE.

- Share your experience in maintaining a clean and organized work area.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement.

- Inquire about the company’s production process and quality control measures.

- Ask about opportunities for professional growth and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barbed Wire Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!