Are you gearing up for an interview for a Barrel Assembly Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Barrel Assembly Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

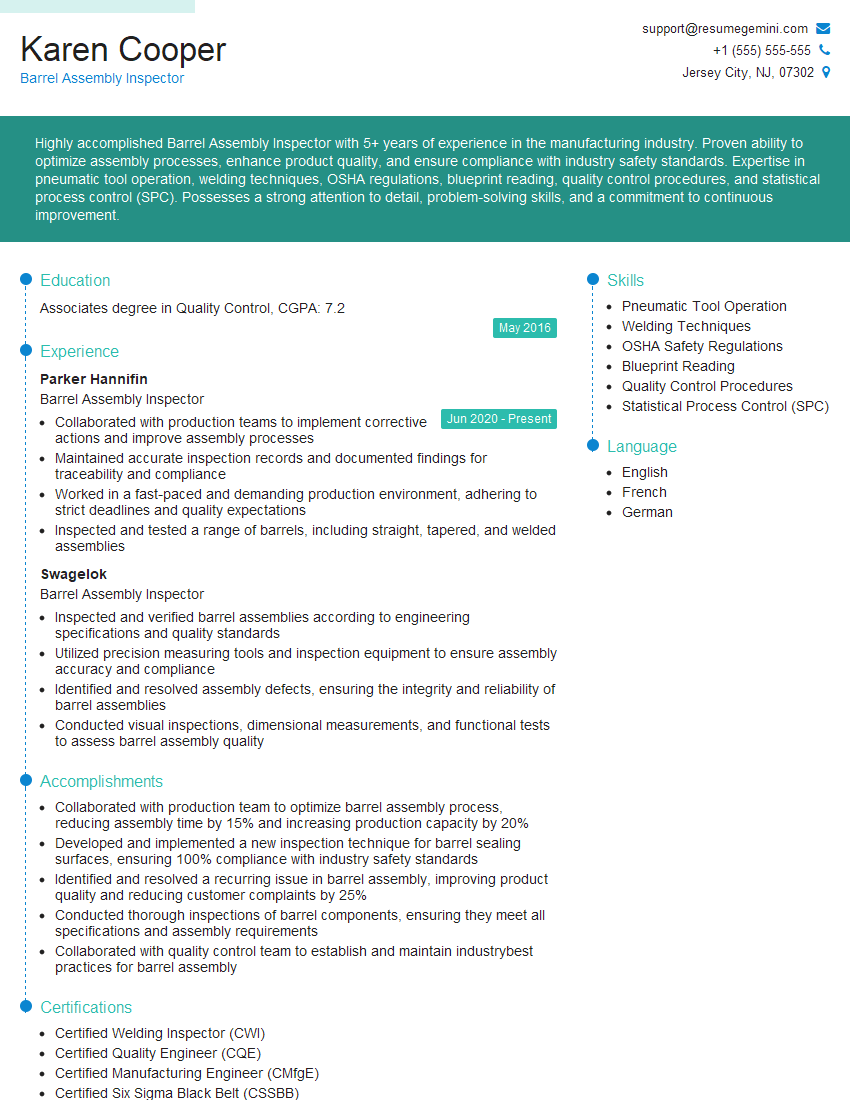

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Assembly Inspector

1. What are the different types of barrel assembly defects?

There are various types of barrel assembly defects, including:

- Head leaks

- Tack leaks

- Hoop leaks

- Chime leaks

- Stave leaks

- Knot holes

- Grain run out

- Sap pockets

2. How do you identify and locate barrel assembly defects?

Visual Inspection

- Examine barrels for any visible defects, such as leaks, cracks, or missing hoops.

- Check the heads for proper seating and tightness.

- Inspect the staves for any damage or splitting.

Leak Testing

- Fill the barrel with water or air.

- Pressurize the barrel to a specified level.

- Listen for any leaks or observe any bubbles forming on the barrel surface.

3. What tools and equipment do you use for barrel assembly inspection?

The tools and equipment used for barrel assembly inspection include:

- Flashlight

- Knife or awl

- Hammer

- Pliers

- Measuring tape

- Pressure gauge

- Leak detection equipment

4. How do you ensure the quality of barrel assemblies?

To ensure the quality of barrel assemblies, I follow these steps:

- Inspect all incoming materials for defects.

- Follow established assembly procedures carefully.

- Thoroughly inspect each barrel assembly for any defects.

- Document all inspections and test results.

- Continuously monitor the assembly process to identify and address any potential issues.

5. What are the safety precautions to take when inspecting barrel assemblies?

The following safety precautions should be taken when inspecting barrel assemblies:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat.

- Inspect barrels in a well-ventilated area.

- Handle barrels carefully to avoid injury.

- Be aware of potential hazards, such as sharp edges or protruding nails.

- Follow all established safety protocols.

6. What is your experience with different barrel materials and their suitability for various applications?

I have experience with a wide range of barrel materials, including:

- Oak

- Maple

- Birch

- Ash

- Cherry

I understand the properties of each material and their suitability for different applications. For example, oak is a durable wood with a tight grain, making it suitable for aging spirits, while maple is a lighter wood with a medium grain, making it suitable for food storage.

7. How do you handle and resolve customer complaints related to barrel assembly defects?

When handling customer complaints related to barrel assembly defects, I follow these steps:

- Listen attentively to the customer’s complaint.

- Inspect the barrel assembly to identify the defect.

- Explain the cause of the defect to the customer.

- Offer a solution to resolve the issue, such as repairing or replacing the barrel assembly.

- Follow up with the customer to ensure satisfaction.

8. What are the industry standards and regulations for barrel assembly inspection?

The following are some of the industry standards and regulations for barrel assembly inspection:

- The Cooperage Institute of America (CIA) Standards

- The International Organization for Standardization (ISO) 9001:2015

- The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- The Food and Drug Administration (FDA) Good Manufacturing Practices (GMPs)

9. How do you stay up-to-date on the latest barrel assembly inspection techniques and industry best practices?

I stay up-to-date on the latest barrel assembly inspection techniques and industry best practices through the following:

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Consulting with experts in the field

10. How do you manage a team of barrel assembly inspectors?

Training and Development

- Provide comprehensive training to new inspectors.

- Identify training needs and provide ongoing development opportunities.

- Ensure that inspectors are certified and up-to-date on industry standards.

Supervision and Communication

- Regularly supervise inspectors to ensure they are following procedures and meeting quality standards.

- Provide clear instructions and communicate expectations effectively.

- Foster a positive and collaborative work environment.

Performance Evaluation and Improvement

- Regularly evaluate inspector performance and provide feedback.

- Identify areas for improvement and develop plans to address them.

- Set performance goals and provide incentives for achieving them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Assembly Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Assembly Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Assembly Inspectors are responsible for ensuring the quality of barrel assemblies. They inspect barrels for defects, measure dimensions, and perform tests to ensure that they meet specifications. The primary goal of a Barrel Assembly Inspector is to maintain the quality and safety of products.

1. Inspection of Barrel Components

Inspecting and verifying the dimensions, materials, and finishes of individual barrel components.

- Examine metal hoops for proper size, shape, and thickness.

- Inspect wooden staves for any cracks, knots, or other defects.

2. Assembly and Measurement

Monitoring the assembly process to ensure proper techniques and procedures are followed.

- Verify that barrel components are assembled correctly and securely.

- Measure and record barrel dimensions, ensuring they meet specifications.

3. Testing and Analysis

Performing various tests to assess the functionality and integrity of barrel assemblies.

- Conduct pressure tests to check for leaks or weaknesses.

- Analyze test results and identify any potential issues.

4. Quality Control and Reporting

Maintaining accurate records and providing feedback on the quality of barrel assemblies.

- Document inspection findings and report any non-conformances.

- Communicate with production teams to address quality issues and improve processes.

Interview Tips

Preparing for a Barrel Assembly Inspector interview requires a thorough understanding of the role and its responsibilities. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Candidates should thoroughly research the company and the specific role they are applying for. This demonstrates enthusiasm and genuine interest in the position.

- Visit the company website and LinkedIn page to learn about their products, values, and industry standing.

- Review the job description carefully and identify the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

Candidates should emphasize their relevant experience and skills that align with the job requirements.

- Showcase previous experience in barrel assembly or inspection, highlighting specific techniques and methodologies.

- Quantify accomplishments and provide specific examples of how your skills contributed to the success of past projects.

3. Prepare for Technical Questions

Interviewers will likely ask technical questions to assess your understanding of barrel assembly processes and testing methods.

- Review common inspection techniques, such as visual inspection, dimensional measurement, and pressure testing.

- Be prepared to discuss different types of barrel defects and their potential causes.

4. Emphasize Quality Control and Attention to Detail

Barrel Assembly Inspectors play a crucial role in maintaining product quality and safety. Emphasize your commitment to quality control and attention to detail.

- Describe your understanding of quality standards and regulations related to barrel assembly.

- Provide examples of your ability to identify and address quality issues effectively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Assembly Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!