Feeling lost in a sea of interview questions? Landed that dream interview for Barrel Cooper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Barrel Cooper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

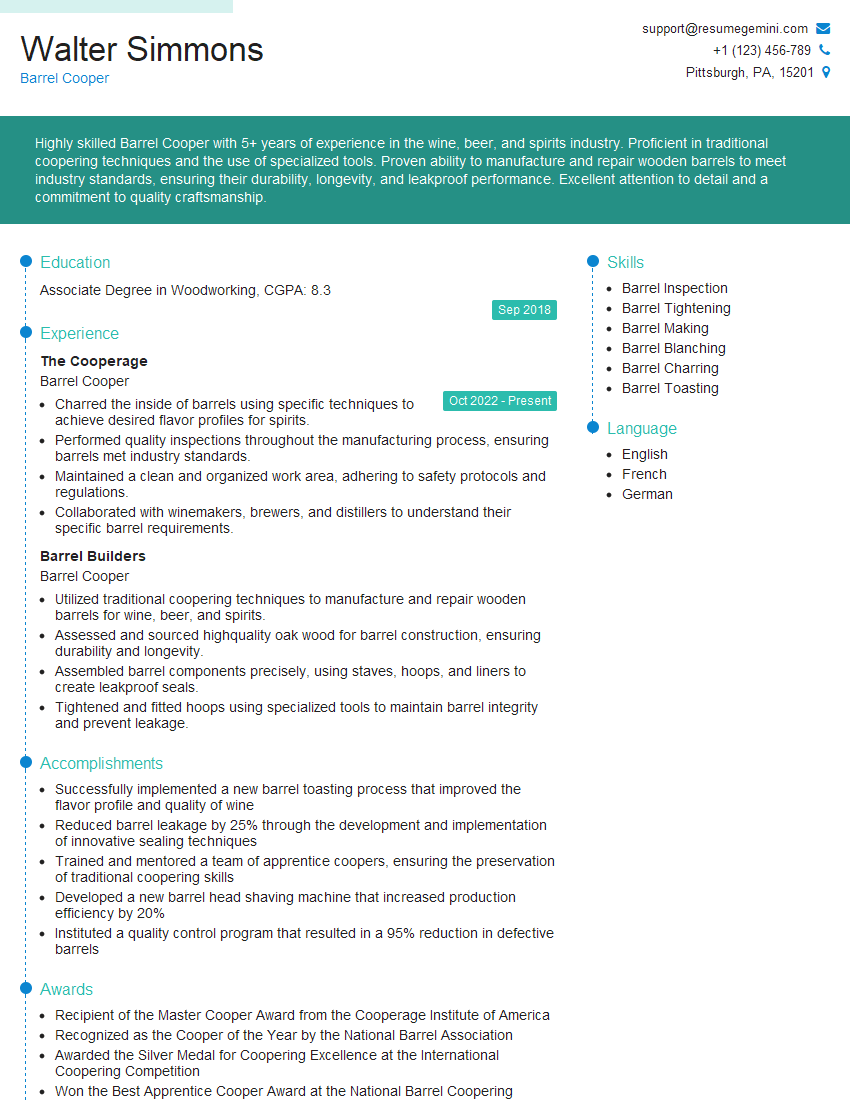

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Cooper

1. Describe the process of seasoning a whiskey barrel.

- Begin by filling the barrel with hot water to expand the wood and open the pores.

- Empty the barrel and let it air dry for several days.

- Fill the barrel with low-proof whiskey and let it sit for several weeks.

- Empty the barrel and fill it with higher-proof whiskey.

- Repeat the filling and emptying process several times, gradually increasing the proof of the whiskey each time.

- Once the barrel has been seasoned, it is ready to be filled with whiskey for aging.

2. What are the different types of wood used to make whiskey barrels?

- American oak: The most common type of wood used for whiskey barrels, American oak imparts flavors of vanilla, caramel, and spice.

- French oak: French oak imparts flavors of dried fruit, chocolate, and baking spices.

- Spanish oak: Spanish oak imparts flavors of tobacco, leather, and earth.

- Portuguese oak: Portuguese oak imparts flavors of citrus, honey, and almonds.

- Japanese oak: Japanese oak imparts flavors of sandalwood, incense, and ginger.

Factors affecting the choice of wood:

- The type of whiskey being aged

- The desired flavor profile

- The budget

3. What is the average lifespan of a whiskey barrel?

The average lifespan of a whiskey barrel is 5-7 years. However, some barrels can last for up to 10 years or more.

4. What are the signs that a whiskey barrel is no longer good for use?

- Leaks: A leaking barrel will allow whiskey to escape and will need to be replaced.

- Mold: Mold can grow on the inside of a barrel if it is not properly maintained. Mold can contaminate the whiskey and make it undrinkable.

- Charred wood: Charred wood can impart a bitter flavor to whiskey. If the wood on the inside of a barrel has been charred, it will need to be replaced.

- Excessive wear and tear: A barrel that has been heavily used may show signs of wear and tear, such as dents, scratches, or cracks. A barrel with excessive wear and tear may not be able to hold whiskey properly and will need to be replaced.

5. What are your responsibilities as a Barrel Cooper?

- Inspecting and maintaining whiskey barrels

- Repairing and replacing damaged barrels

- Seasoning new barrels

- Working with distillers to select the right barrels for their whiskey

- Keeping accurate records of all barrel-related activities

6. What are the challenges of being a Barrel Cooper?

- Working with heavy and awkward objects: Barrels are heavy and can be difficult to move. This can be a challenge, especially for those who are not used to working with heavy objects.

- Exposure to chemicals: Barrels are made of wood, which can be treated with chemicals. These chemicals can be harmful if they are inhaled or ingested. Barrel Coopers must take precautions to protect themselves from exposure to these chemicals.

- Repetitive motions: Barrel Coopers often perform repetitive motions, such as hammering and sanding. These repetitive motions can lead to injuries, such as carpal tunnel syndrome.

- Working in a noisy environment: Barrel Coopers often work in noisy environments, such as cooperages. This noise can be harmful to hearing if it is not protected.

7. What are the rewards of being a Barrel Cooper?

- Job satisfaction: Barrel Coopers take pride in their work and know that they are playing an important role in the production of whiskey.

- Good pay: Barrel Coopers can earn a good wage, especially those who have experience and skills.

- Job security: Barrel Coopers are in high demand, especially in the whiskey industry. This means that they are likely to have job security.

- Opportunity for advancement: Barrel Coopers can advance to positions such as Master Cooper or Cooperage Manager.

8. What is the most important thing you have learned as a Barrel Cooper?

The most important thing I have learned as a Barrel Cooper is the importance of quality. Every barrel that I make is a reflection of my skills and craftsmanship. I take pride in my work and I want to make sure that every barrel is of the highest quality.

9. What is your favorite part of being a Barrel Cooper?

My favorite part of being a Barrel Cooper is seeing the finished product. After I have spent weeks or even months working on a barrel, it is very satisfying to see it filled with whiskey and ready to be aged. I know that my work has played a part in creating something that will be enjoyed by people for years to come.

10. What advice would you give to someone who is considering becoming a Barrel Cooper?

- Be prepared to work hard: Barrel Coopering is a physically demanding job.

- Be willing to learn: There is always something new to learn about barrel making.

- Take pride in your work: Every barrel that you make is a reflection of your skills and craftsmanship.

- Be patient: It takes time to become a skilled Barrel Cooper.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Cooper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Cooper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Coopers are highly skilled craftsmen responsible for constructing and repairing wooden barrels and casks. These barrels are used in various industries, including winemaking, brewing, and distilling. The key responsibilities of a Barrel Cooper include:

1. Barrel Making and Assembly

Designing and creating new barrels from raw materials such as oak, pine, or cedar.

- Selecting and cutting the appropriate wood for the barrel’s size and purpose.

- Shaping and bending the wooden staves to form the barrel’s body.

- Fitting and securing the staves together using hoops and rivets.

- Applying a sealant to the barrel to ensure it is watertight.

2. Barrel Repair and Maintenance

Inspecting and repairing existing barrels to maintain their integrity and functionality.

- Identifying and fixing leaks or cracks in the barrel’s body or hoops.

- Replacing damaged or worn-out staves.

- Refinishing or re-coating the barrel to improve its appearance and protect it from the elements.

3. Quality Control and Inspection

Ensuring that barrels meet specific quality standards and specifications.

- Measuring and testing the barrel’s dimensions, capacity, and watertightness.

- Inspecting the barrel’s surface for imperfections or damage.

- Approving or rejecting barrels based on their compliance with established standards.

4. Cooperage Management

Maintaining and organizing the cooperage, ensuring efficient operations and safety.

- Maintaining a clean and organized work area.

- Storing and handling tools, materials, and barrels properly.

- Following safety protocols and regulations while operating machinery and handling heavy objects.

Interview Preparation Tips

Preparing thoroughly for a Barrel Cooper interview can significantly increase your chances of success. Here are some effective tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and reputation. Research the winemaking, brewing, or distilling industry to understand the context of the role.

2. Practice Your Skills and Knowledge

Review techniques for barrel making, repair, and quality control. Practice measuring and testing barrels to demonstrate your proficiency.

3. Showcase Your Craftsmanship

Highlight your attention to detail, precision, and commitment to quality craftsmanship. Provide examples of projects you’ve worked on that demonstrate your skills.

4. Prepare for Common Interview Questions

Anticipate questions about your experience, qualifications, and passion for barrel making. Prepare thoughtful answers that emphasize your strengths and how they align with the job requirements.

5. Dress and Arrive Professionally

First impressions matter. Dress appropriately for the interview and arrive punctually to show respect and professionalism.

6. Ask Thoughtful Questions

At the end of the interview, prepare insightful questions to demonstrate your interest in the role and the company. This shows that you’re engaged and genuinely interested in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Cooper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.