Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Barrel Dedenting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Barrel Dedenting Machine Operator so you can tailor your answers to impress potential employers.

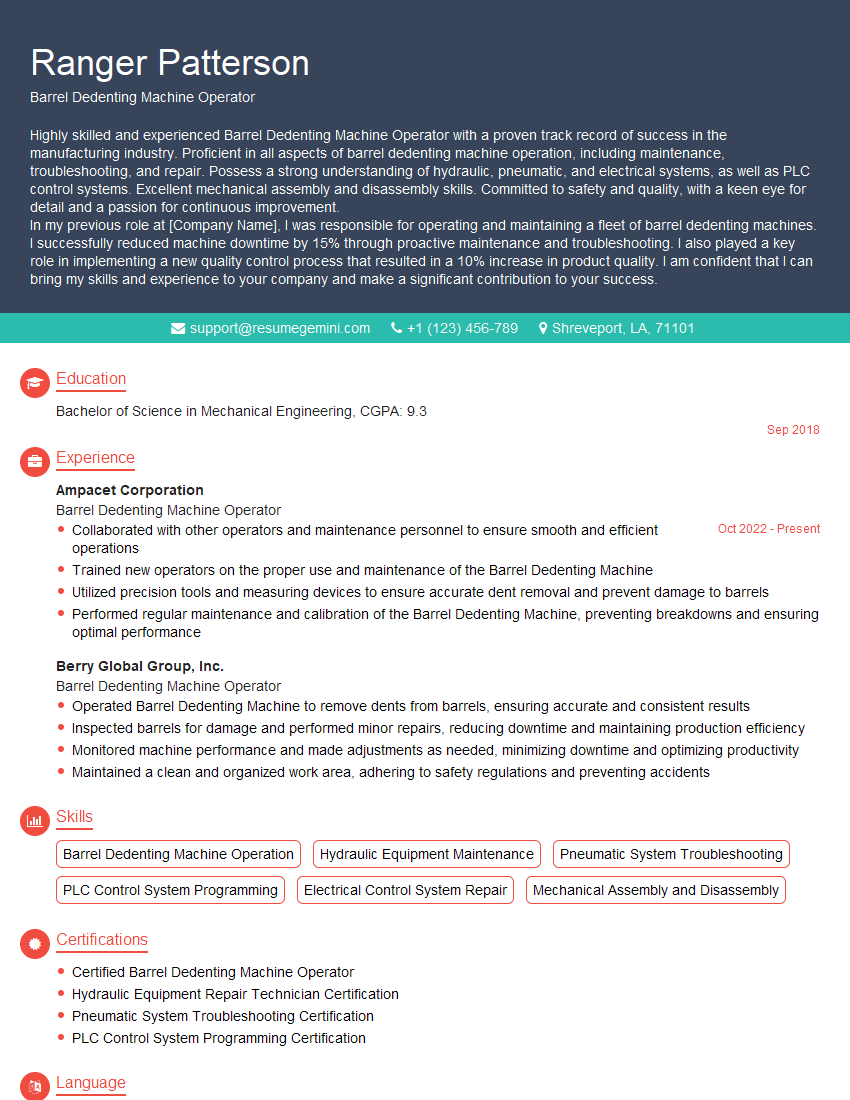

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Dedenting Machine Operator

1. What are the key responsibilities of a Barrel Dedenting Machine Operator?

- Operate, inspect, and maintain barrel dedenting machines to remove dents and damage.

- Set up, adjust, and calibrate equipment to achieve optimal performance.

- Inspect and measure barrels before and after dedenting to ensure quality standards are met.

2. How do you ensure the accuracy and precision of the barrel dedenting process?

Maintenance of Equipment

- Regularly inspect and calibrate equipment to ensure proper functioning.

- Identify and replace worn or damaged components to maintain optimal performance.

Quality Control

- Establish clear quality standards for dedented barrels.

- Use measuring tools and gauges to verify that barrels meet specifications.

3. What are some common challenges you have faced in operating a barrel dedenting machine, and how did you overcome them?

- Overcoming Difficult Dents: Use specialized techniques and tools to remove stubborn dents without damaging the barrel.

- Balancing Quality and Efficiency: Streamline the dedenting process while maintaining high accuracy and precision.

4. How do you prioritize tasks and manage time effectively when working in a fast-paced manufacturing environment?

- Prioritizing Tasks: Assess the urgency and importance of tasks to allocate resources efficiently.

- Time Management: Utilize time management techniques, such as the Pomodoro Technique, to maximize productivity.

5. What is your experience in using statistical process control tools to monitor and improve the performance of the barrel dedenting process?

- Data Collection and Analysis: Utilize statistical tools to collect and analyze data on dedenting operations.

- Process Optimization: Identify areas for improvement and implement changes to enhance process efficiency and accuracy.

6. How do you stay up-to-date with the latest advancements in barrel dedenting technology?

- Attending Industry Events: Participate in conferences and workshops to learn about new technologies.

- Research and Development: Actively engage in research and development activities to explore innovative methods.

7. What safety precautions do you take when operating a barrel dedenting machine?

- PPE and Work Environment: Wear appropriate personal protective equipment (PPE) and ensure a safe work environment.

- Machine Operation: Follow safety guidelines for machine operation, including lockout/tagout procedures.

8. How do you handle barrels with different sizes and materials?

- Assessment of Barrel Characteristics: Determine the size, material, and condition of barrels to adjust machine settings.

- Customization of Dedenting Parameters: Modify dedenting parameters, such as pressure and dwell time, to accommodate different materials.

9. How do you ensure the traceability of barrels throughout the dedenting process?

- Unique Identification: Implement a system to assign unique identifiers to barrels for tracking purposes.

- Data Management: Maintain records of dedenting operations associated with each barrel for traceability.

10. How do you approach continuous improvement in your role as a Barrel Dedenting Machine Operator?

- Performance Evaluation: Regularly assess personal performance and identify areas for improvement.

- Collaboration and Feedback: Seek feedback from colleagues and supervisors to gain diverse perspectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Dedenting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Dedenting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key job responsibilities of Barrel Dedenting Machine Operator:

A Barrel Dedenting Machine Operator is responsible for operating and maintaining a barrel dedenting machine, which removes dents and other imperfections from barrels. The key job responsibilities of a Barrel Dedenting Machine Operator include:

1. Operating the barrel dedenting machine:

This involves loading and unloading barrels, setting up the machine according to the type of barrel being processed, and monitoring the machine’s operation.

- Loading and unloading barrels

- Setting up the machine

- Monitoring the machine’s operation

2. Inspecting barrels for defects:

This involves visually inspecting barrels for dents, scratches, and other imperfections.

- Visually inspecting barrels

- Identifying and marking defects

3. Maintaining the barrel dedenting machine:

This involves cleaning and lubricating the machine, as well as performing minor repairs.

- Cleaning and lubricating the machine

- Performing minor repairs

4. Keeping records of barrel dedenting operations:

This involves recording the type of barrels processed, the number of barrels processed, and any defects that were found.

- Recording the type of barrels processed

- Recording the number of barrels processed

- Recording any defects that were found

Interview tips for Barrel Dedenting Machine Operator:

To ace the interview for a Barrel Dedenting Machine Operator position, it is important to:

1. Research the company and the position:

This will help you understand the company’s culture, the specific requirements of the position, and the qualifications that the interviewer is looking for.

- Visit the company’s website

- Read about the company on social media

- Talk to people who work at the company

2. Practice answering common interview questions:

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can be confident and articulate during the interview.

- Write down your answers to common interview questions

- Practice answering these questions out loud

- Get feedback from a friend or family member

3. Be prepared to talk about your experience:

The interviewer will want to know about your experience operating and maintaining barrel dedenting machines. Be sure to highlight your skills and accomplishments, and be prepared to provide specific examples of your work.

- Quantify your accomplishments

- Use the STAR method to answer questions

- Be prepared to discuss your experience in detail

4. Dress professionally and arrive on time:

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Arrive on time

- Be polite and respectful

Next Step:

Now that you’re armed with the knowledge of Barrel Dedenting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Barrel Dedenting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini