Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Barrel Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

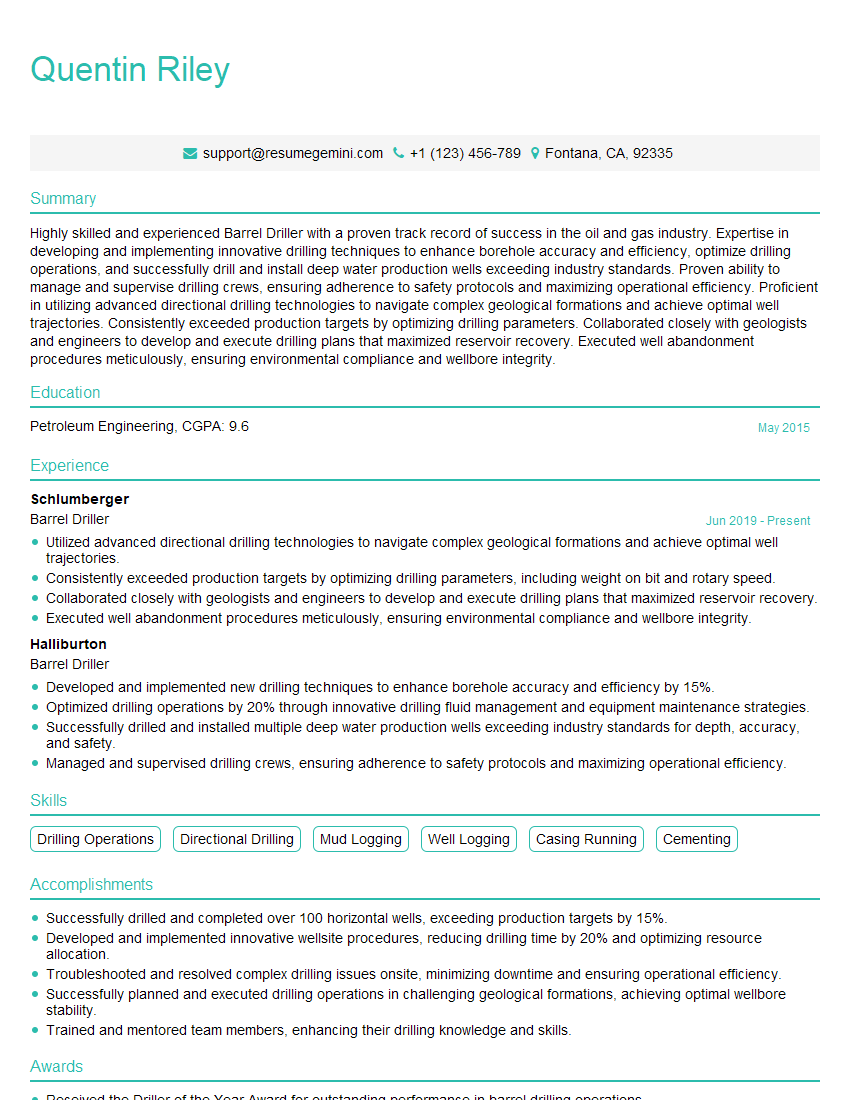

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Driller

1. How do you determine the correct weight-on-bit (WOB) for a given drilling operation?

- Assess formation characteristics (hardness, porosity)

- Calculate bit tooth loading to ensure optimal cutting efficiency

- Monitor torque and drilling parameters to adjust WOB accordingly

- Utilize downhole tools like pressure while drilling (PWD) and measurement-while-drilling (MWD) to optimize performance

2. Describe the process of acidizing a wellbore.

Pre-Acidizing Phase

- Analyze formation characteristics and plan acid type and volume

- Prepare wellbore by isolating intervals and circulating fluids

Acidizing Phase

- Pump acid solution into the wellbore to dissolve minerals

- Monitor pressure and temperature to ensure effective acid penetration

Post-Acidizing Phase

- Circulate wellbore to remove acid and dissolved materials

- Evaluate acidization effectiveness using logging tools

3. What factors influence the selection of drilling fluids for a particular operation?

- Formation characteristics (lithology, porosity, permeability)

- Drilling conditions (depth, temperature, pressure)

- Wellbore stability and hole cleaning requirements

- Environmental regulations and waste management considerations

- Cost and availability of drilling fluids

4. Describe the purpose and operation of a mud logging unit.

- Monitors drilling parameters and fluid properties (e.g., flow rate, cuttings size, formation gas)

- Identifies geological formations and determines hydrocarbon presence

- Assesses formation pressure and stability to optimize drilling operations

- Provides real-time data for informed decision-making

5. How do you calculate hook load and what are its implications for drilling operations?

- Hook load = Weight of drill string + Weight of drill collar + Weight of mud in the drill string

- Excessive hook load can exceed rig capacity and cause equipment failure

- Insufficient hook load can lead to poor weight transfer and drilling inefficiencies

- Monitoring hook load helps optimize drilling parameters and prevent accidents

6. Explain the different types of drilling bits and their suitability for various drilling conditions.

- Rugged and suitable for hard formations

- Efficient for soft to medium-hard formations

- Used for soft formations with minimum penetration

- Versatile with rolling cutters on a rotating cone

Roller Cone Bits

PDC (Polycrystalline Diamond Compact) Bits

Drag Bits

Tricone Bits

7. Describe the safety procedures for handling and transporting drilling fluids.

- Wear protective gear (respirator, gloves, coveralls)

- Inspect equipment regularly and maintain spill containment measures

- Follow proper disposal and waste management guidelines

- Provide adequate ventilation to prevent gas accumulation

- Train personnel on safe handling practices

8. How do you troubleshoot and resolve common drilling problems such as lost circulation or stuck pipe?

Lost Circulation

- Identify the cause (e.g., fractured formations, drilling too fast)

- Attempt controlled fluid loss by increasing mud weight or using lost circulation materials

Stuck Pipe

- Determine the reason (e.g., differential sticking, mechanical issue)

- Apply appropriate methods (e.g., jarring, rotating, mud additives)

9. Explain the importance of wellbore integrity and describe methods used to maintain it.

- Prevents fluid loss, gas migration, and wellbore collapse

- Techniques include:

- Proper casing and cementing

- Wellbore cleaning and conditioning

- Monitoring for pressure imbalances and fluid flow

10. Describe the environmental impact of drilling operations and discuss measures to mitigate it.

- Waste generation (drilling fluids, cuttings)

- Atmospheric emissions (e.g., methane)

- Water contamination (e.g., spills, leaks)

- Proper waste management and disposal

- Reducing emissions through equipment efficiency and flaring systems

- Implementing spill prevention and response plans

- Collaborating with regulatory agencies and environmental organizations

Impacts

Mitigation Measures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Drillers are responsible for operating and maintaining drilling equipment used to create holes in the ground for various purposes, such as water wells, geothermal wells, and oil and gas wells. Their key responsibilities include:

1. Drilling Operations

Operate drilling equipment, including rotary rigs, air hammers, and mud pumps.

- Monitor drilling parameters, such as depth, pressure, and flow rate.

- Adjust drilling parameters to optimize performance and prevent equipment damage.

2. Equipment Maintenance

Perform routine maintenance on drilling equipment, including lubrication, repairs, and adjustments.

- Identify and troubleshoot equipment malfunctions.

- Coordinate with mechanics for major repairs.

3. Safety and Compliance

Follow safety protocols and regulations to ensure a safe work environment.

- Wear appropriate safety gear, such as hard hats, gloves, and safety glasses.

- Inspect equipment for potential hazards before starting operations.

4. Communication and Recordkeeping

Communicate effectively with clients, supervisors, and other team members.

- Maintain accurate records of drilling operations, including daily reports and performance data.

- Provide technical support and advice to clients and other stakeholders.

Interview Tips

To ace an interview for a Barrel Driller position, it is crucial to prepare thoroughly and demonstrate your skills and experience. Here are some tips to help you:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry publications, and social media pages. This will give you a good understanding of their culture, values, and business objectives. Research the specific Barrel Driller role and its responsibilities to ensure you can articulate how your skills align with the position.

- Example: “I have thoroughly reviewed your company’s website and am impressed by your commitment to sustainability in the drilling industry. My experience in eco-friendly drilling techniques would be a valuable asset to your team.”

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining drilling equipment. Provide specific examples of your experience and any certifications or training you have completed. Quantify your accomplishments using specific metrics whenever possible.

- Example: “In my previous role, I consistently exceeded drilling efficiency targets by 15% through optimizing drilling parameters and implementing innovative techniques.”

3. Showcase Your Safety Knowledge

Safety is paramount in the drilling industry. Highlight your understanding of safety protocols and regulations, as well as your commitment to maintaining a safe work environment. Discuss your experience in identifying and mitigating potential hazards.

- Example: “I have received comprehensive training in workplace safety regulations and have implemented a rigorous safety program at my previous job site, resulting in zero accidents during my tenure.”

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your skills and experience. Practice answering these questions aloud to improve your articulation and confidence.

- Example: “Tell me about your experience in operating rotary drilling rigs. Discuss the challenges you have encountered and how you have overcome them.”

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the organization.

- Example: “What are the company’s plans for expanding its drilling operations into new geographic regions?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!