Feeling lost in a sea of interview questions? Landed that dream interview for Barrel Endshake Adjuster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Barrel Endshake Adjuster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

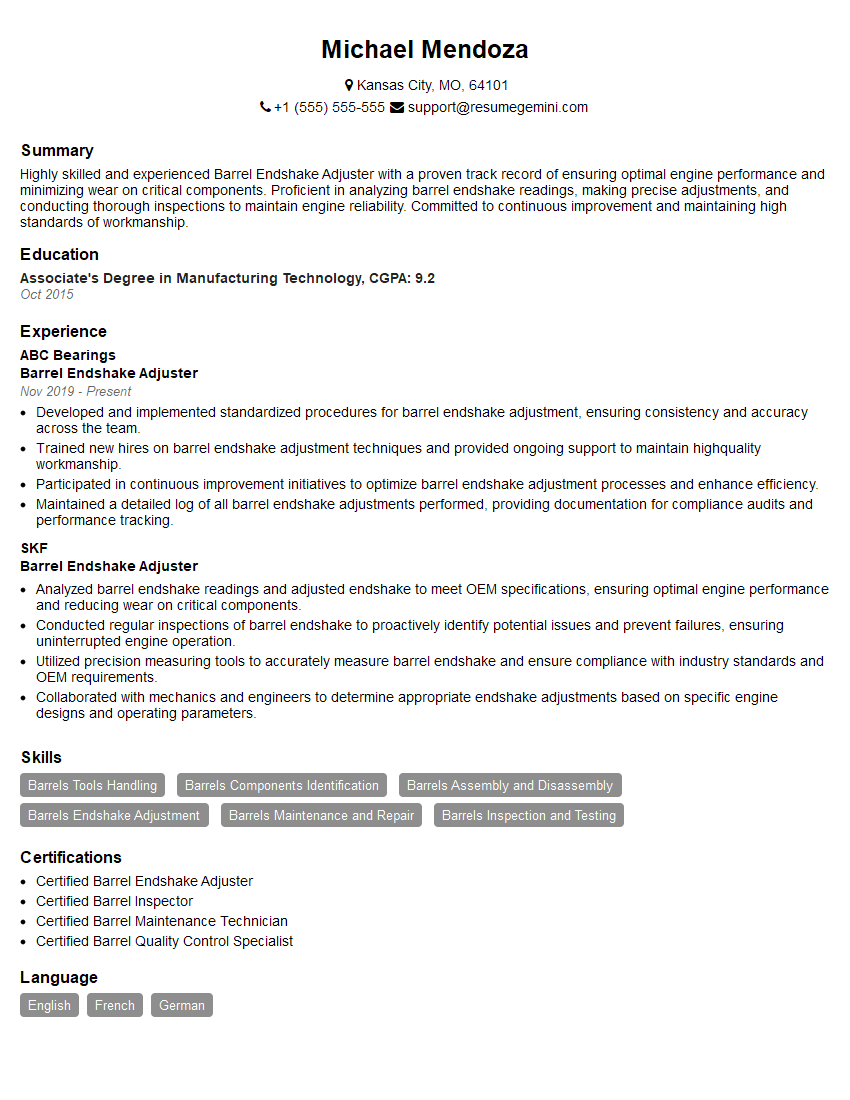

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Endshake Adjuster

1. Explain the importance of endshake in a pump?

- Ensures smooth operation by preventing rotor rubbing against the casing.

- Reduces vibration and noise.

- Prevents premature bearing failure.

- Enhances pump efficiency.

2. Describe the different methods used to adjust endshake in a centrifugal pump?

Axial adjustment

- Using shims or gaskets between the bearing housing and the pump casing.

- Tightening or loosening the impeller nut.

Radial adjustment

- Adjusting the position of the bearings relative to the shaft.

- Using bearing spacers or shims.

Combination axial and radial adjustment

- A combination of both axial and radial methods.

- Provides precise control over endshake.

3. What are the factors that influence the amount of endshake required in a pump?

- Pump operating speed.

- Type of bearings used.

- Diameter and length of the shaft.

- Fluid viscosity and temperature.

4. How do you determine the correct endshake for a specific pump?

Using manufacturer’s recommendations, pump performance curves, and field experience. Consider the factors mentioned in question 3 to make an informed decision.

5. What are the consequences of excessive or insufficient endshake?

Excessive endshake

- Premature bearing failure due to excessive axial loads.

- Reduced pump efficiency.

- Noise and vibration.

Insufficient endshake

- Rotor rubbing against the casing, leading to wear and damage.

- Sealing issues.

- Increased vibration and noise.

6. How often should endshake be adjusted?

Depends on the pump operating conditions, but it is generally recommended to check endshake during scheduled maintenance or if any changes in pump performance are observed.

7. What safety precautions should be taken when adjusting endshake?

- Follow manufacturer’s instructions and safety guidelines.

- Ensure the pump is isolated from power and fluid supply.

- Use appropriate tools and equipment.

- Wear proper safety gear.

8. Describe the role of a dial indicator in measuring endshake?

- Used to measure the axial movement of the shaft.

- Precise and accurate measurement tool.

- Attached to the shaft or casing to detect movement.

9. How do you use a feeler gauge to measure endshake?

- Insert the feeler gauge between the shaft and the casing.

- Move the feeler gauge back and forth to determine the clearance.

- Record the thickness of the feeler gauge that fits snugly.

10. What are some common mistakes made when adjusting endshake?

- Overtightening or undertightening adjustment nuts.

- Not using the correct adjustment method for the specific pump.

- Ignoring or misinterpreting manufacturer’s instructions.

- Failing to check the endshake after making adjustments.

- Adjusting endshake without considering the operating conditions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Endshake Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Endshake Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Endshake Adjusters are responsible for ensuring the proper functioning of machinery and equipment through precise adjustments to barrel endshake.

1. Endshake Measurement and Adjustment

Measuring and adjusting barrel endshake values to meet manufacturer specifications.

- Using specialized tools and gauges to measure endshake accurately.

- Making fine adjustments to barrel nuts and shims to achieve optimal endshake.

2. Equipment Monitoring and Maintenance

Monitoring equipment operation for abnormal endshake conditions.

- Identifying and troubleshooting causes of excessive endshake.

- Performing preventive maintenance tasks to minimize endshake issues.

3. Record-Keeping and Documentation

Maintaining detailed records of endshake measurements and adjustments.

- Generating reports and summaries for analysis and quality control purposes.

- Collaborating with engineers and maintenance teams to optimize endshake performance.

4. Safety and Compliance

Adhering to all safety regulations and industry standards related to barrel endshake adjustments.

- Using appropriate personal protective equipment.

- Following lockout/tagout procedures to prevent accidents.

Interview Tips

Preparing for an interview for a Barrel Endshake Adjuster position requires thorough knowledge of the job responsibilities and technical requirements. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and industry by researching their operations, products, and market position. This shows the interviewer that you are serious about the opportunity and have taken the time to understand their business.

- Visit the company website and review their mission statement, values, and recent news.

- Explore industry publications and online resources to gain insights into the latest trends and technologies.

2. Practice Answering Common Interview Questions

Anticipate and prepare for common interview questions related to your technical skills, experience, and motivations. Practice your answers aloud or with a friend to improve your delivery and confidence.

- Explain your understanding of barrel endshake and its importance in machinery operation.

- Describe your experience in measuring and adjusting barrel endshake to specific tolerances.

3. Highlight Your Problem-Solving Abilities

Emphasize your ability to identify and resolve endshake issues in equipment. Provide examples of how you have used troubleshooting techniques to diagnose and correct problems.

- Talk about a time when you identified excessive endshake and implemented a solution to minimize its impact on equipment performance.

- Discuss your understanding of different factors that can affect barrel endshake, such as temperature and wear.

4. Showcase Your Teamwork and Communication Skills

Explain how you effectively collaborate with engineers, maintenance teams, and other stakeholders to optimize barrel endshake performance and ensure equipment reliability.

- Provide examples of how you have coordinated with others to troubleshoot endshake issues and implement corrective actions.

- Highlight your ability to communicate technical information clearly and effectively to non-technical audiences.

5. Be Prepared to Talk About Your Career Goals and Aspirations

Discuss your long-term career goals and aspirations. Explain how the Barrel Endshake Adjuster role aligns with your career path and how you see it contributing to your professional development.

- Express your interest in learning and growing within the field of machinery maintenance and reliability.

- Explain how the company’s values and commitment to innovation align with your own career aspirations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Endshake Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!