Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Barrel Liner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Barrel Liner so you can tailor your answers to impress potential employers.

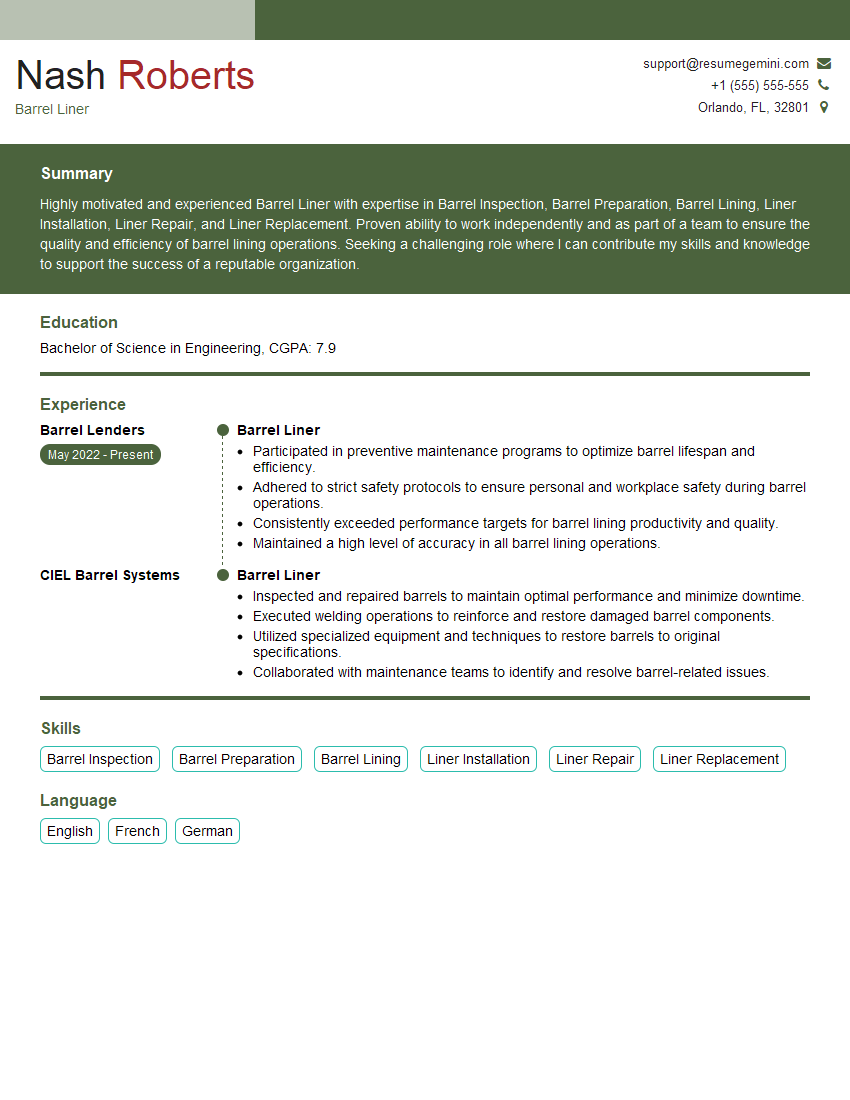

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Liner

1. What are the different types of barrel liners and their applications?

Barrel liners are used to protect the interior of barrels from damage and contamination. There are different types of barrel liners, each with its own specific application.

- Polyethylene liners: These liners are made of high-density polyethylene (HDPE) and are known for their durability and resistance to chemicals and moisture. They are commonly used in the packaging and transportation of liquids, powders, and other sensitive materials.

- Polypropylene liners: These liners are made of polypropylene (PP) and are known for their strength and flexibility. They are commonly used in the packaging and transportation of food products, pharmaceuticals, and other items that require protection from moisture and contamination.

- Paper liners: These liners are made of paper and are used to protect the interior of barrels from moisture and dust. They are commonly used in the packaging and transportation of dry goods, such as grains, powders, and solids.

- Aluminum liners: These liners are made of aluminum and are used to protect the interior of barrels from moisture, oxygen, and light. They are commonly used in the packaging and transportation of sensitive materials, such as pharmaceuticals, chemicals, and electronics.

2. What are the factors to consider when selecting a barrel liner?

Compatibility with the barrel

- The liner must be compatible with the size and shape of the barrel.

- The liner must be made of a material that is resistant to the chemicals and temperatures that will be encountered.

Compatibility with the product

- The liner must be compatible with the product that will be stored in the barrel.

- The liner must not leach any chemicals into the product.

Cost

- The cost of the liner must be taken into account.

- The cost of the liner should be compared to the cost of replacing the barrel if it is damaged.

3. What are the advantages of using barrel liners?

- Barrel liners protect the interior of barrels from damage and contamination.

- Barrel liners can extend the life of barrels.

- Barrel liners make it easier to clean and maintain barrels.

- Barrel liners can help to prevent spills and leaks.

4. What are the disadvantages of using barrel liners?

- Barrel liners can increase the cost of packaging and transportation.

- Barrel liners can make it more difficult to load and unload barrels.

5. What are the different methods of installing barrel liners?

- Manual installation: This method involves manually inserting the liner into the barrel and securing it with straps or ties.

- Mechanical installation: This method involves using a machine to insert the liner into the barrel and secure it.

6. What are the safety precautions that should be taken when working with barrel liners?

- Wear gloves and other protective clothing when handling barrel liners.

- Use caution when inserting and removing barrel liners.

- Dispose of used barrel liners properly.

7. What are the latest developments in barrel liner technology?

- New materials: New materials are being developed that are more durable, resistant to chemicals, and easier to install.

- New designs: New designs are being developed that are more efficient and easier to use.

8. What are the challenges facing the barrel liner industry?

- Rising costs: The cost of raw materials used to make barrel liners is rising.

- Increasing competition: There is increasing competition from other packaging materials.

9. What are the future prospects for the barrel liner industry?

- Growth in demand: The demand for barrel liners is expected to grow in the coming years.

- New technologies: New technologies are expected to make barrel liners more efficient and easier to use.

10. What are your strengths and weaknesses as a barrel liner?

- Strengths: I have experience in selecting, installing, and maintaining barrel liners.

- I am familiar with the different types of barrel liners and their applications.

- I am able to work independently and as part of a team.

- Weaknesses: I have limited experience with the latest developments in barrel liner technology.

- I am not familiar with all of the different safety precautions that should be taken when working with barrel liners.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Barrel Liner is responsible for the safe and efficient installation, repair, and maintenance of barrel liners in various industries. Their key responsibilities include:

1. Liner Installation

Properly installing barrel liners, including preparing the barrel surface, cutting and fitting the liner, and securing it in place using appropriate techniques.

- Selecting and preparing the correct liner material based on the barrel’s application and requirements.

- Inspecting the barrel for any damage or irregularities that may affect liner installation.

2. Liner Maintenance

Performing regular inspections and maintenance of barrel liners to ensure their proper functioning and longevity.

- Monitoring liner condition for signs of wear, leaks, or damage.

- Cleaning and repairing liners as needed to maintain their integrity and performance.

3. Troubleshooting

Identifying and resolving any issues related to barrel liners, such as leaks, tears, or improper fit.

- Diagnosing the cause of liner failure and recommending appropriate solutions.

- Coordinating with other maintenance personnel to ensure timely repairs and minimize downtime.

4. Safety and Compliance

Ensuring compliance with all safety regulations and industry standards related to barrel liner installation and maintenance.

- Properly handling and storing liner materials to prevent damage or contamination.

- Using appropriate safety equipment and following established safety procedures during installation and maintenance activities.

Interview Tips

To prepare effectively for a Barrel Liner interview, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, the industry it serves, and the specific role of a Barrel Liner within that context.

- Visit the company’s website and social media pages to learn about their culture, values, and current projects.

- Research the industry’s latest trends, best practices, and regulatory requirements related to barrel liner installation and maintenance.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in areas such as barrel liner installation, maintenance, and troubleshooting. Provide specific examples of your work.

- Quantify your accomplishments whenever possible. For example, “Installed over 100 barrel liners within a specified timeframe, resulting in increased production efficiency by X%.”

- Showcase your ability to work independently and as part of a team, with a focus on safety and compliance.

3. Prepare for Technical Questions

Expect technical questions related to barrel liner materials, installation techniques, and maintenance procedures.

- Review common types of barrel liners, their properties, and applications.

- Practice describing the steps involved in installing and maintaining barrel liners.

4. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the role and the company.

- Inquire about the company’s growth plans and how the Barrel Liner position contributes to those goals.

- Ask about the specific challenges and opportunities associated with the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Barrel Liner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Barrel Liner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.