Are you gearing up for a career in Barrel Plater? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Barrel Plater and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

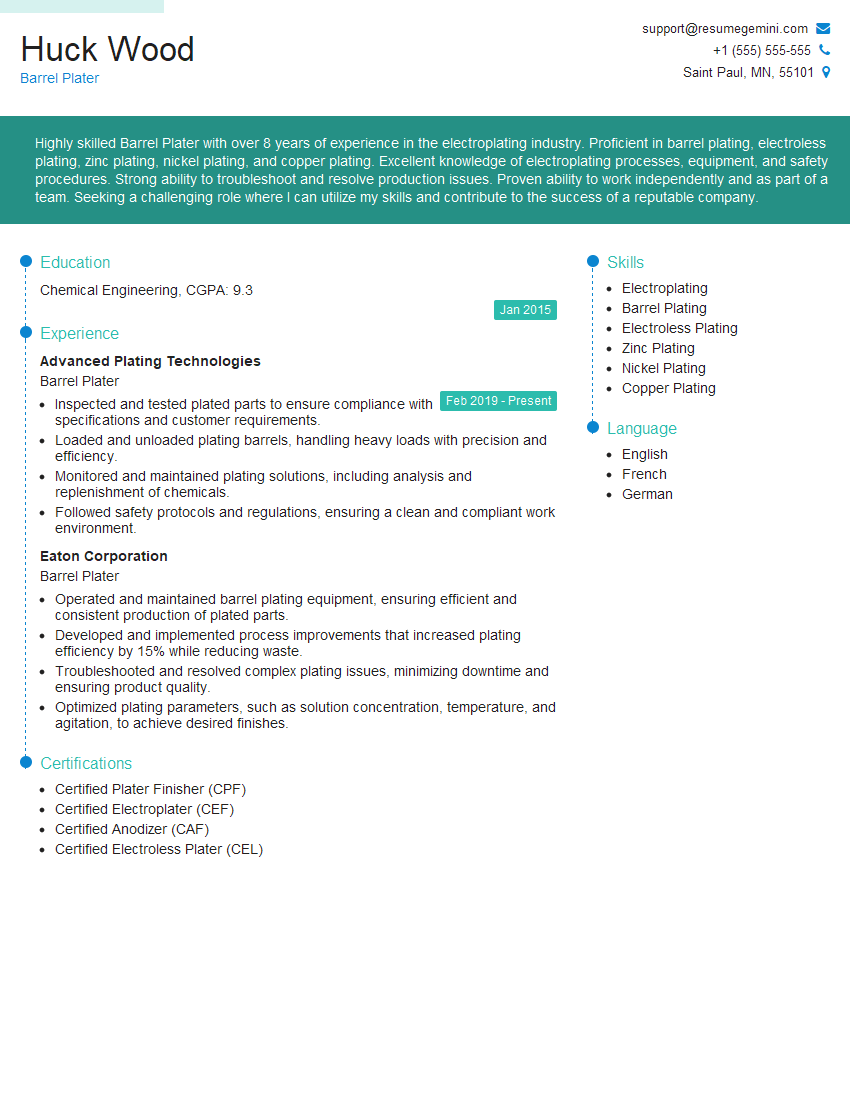

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Plater

1. What is the main objective of barrel plating?

The primary objective of barrel plating is to electroplate small, irregular-shaped components by rotating them in a barrel. The process aims to achieve a uniform coating thickness on the surface of the parts.

2. Describe the different types of barrel plating equipment.

There are two primary types of barrel plating equipment:

- Horizontal barrels: These barrels are ideal for plating small parts that can tumble freely. They rotate horizontally, ensuring even distribution of the solution and coating.

- Vertical barrels: Vertical barrels are suitable for larger or more delicate parts. They rotate vertically, allowing the solution to drip and drain more effectively.

3. What is the purpose of the drag-out tank?

The drag-out tank serves to minimize the amount of plating solution that is carried out of the plating barrel. After the plating process, the barrel is submerged in the drag-out tank, which contains water or a neutralizing solution. This helps prevent the solution from dripping onto the floor or contaminating other processes.

4. How do you determine the appropriate plating time for barrel plating?

The plating time is influenced by the following factors:

- Thickness of the desired plating

- Current density

- Plating solution concentration

- Temperature of the solution

- Surface area of the parts

The optimal plating time is determined through experimentation and experience.

5. What are the common problems encountered in barrel plating, and how do you troubleshoot them?

Some common problems include:

- Poor adhesion: This can be caused by inadequate cleaning or surface preparation, low current density, or improper bath composition.

- Blistering: Blistering can occur due to gas entrapment, high current density, or improper bath temperature.

- Pitting: Pitting is often caused by contamination of the solution or by impurities in the base metal.

Troubleshooting involves identifying the cause of the problem and implementing corrective measures, such as adjusting the process parameters, cleaning the equipment, or filtering the solution.

6. How do you ensure the quality of barrel-plated parts?

Quality assurance involves the following steps:

- Visual inspection: Checking the parts for defects such as scratches, pits, or blisters.

- Thickness testing: Using a coating thickness gauge or cross-sectioning to measure the thickness of the plating.

- Adhesion testing: Performing adhesion tests, such as the tape test or the bend test, to assess the bond strength between the plating and the base metal.

- Corrosion resistance testing: Conducting corrosion tests to determine the resistance of the plating to corrosion.

7. What is the difference between acid copper and alkaline copper plating?

Acid copper plating operates in an acidic solution and typically results in a harder, more wear-resistant coating. Alkaline copper plating, on the other hand, uses an alkaline solution and produces a softer, more ductile coating.

8. How do you prepare a barrel for plating?

Preparing a barrel for plating involves the following steps:

- Cleaning the barrel: Using a detergent or solvent to remove any dirt or contaminants from the barrel.

- Pickling the barrel: Submerging the barrel in an acidic solution to remove any oxide or rust from the metal surface.

- Activating the barrel: Treating the barrel with an oxidizing solution to promote the adhesion of the plating.

9. What are the safety precautions you take when barrel plating?

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE): Such as gloves, apron, safety glasses, and a respirator.

- Ventilating the plating area: To avoid exposure to fumes and mists.

- Handling chemicals properly: Following safety data sheets and disposing of chemicals according to regulations.

10. How do you stay updated with the latest advancements in barrel plating technology?

To stay updated, I engage in activities such as:

- Attending industry conferences and workshops: To learn about new techniques and equipment.

- Reading industry publications and journals: To stay informed about the latest research and developments.

- Networking with other professionals: To exchange knowledge and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Barrel Plater is a skilled metalworker responsible for electroplating various metal objects to enhance their durability, appearance, and corrosion resistance. They use a specialized barrel plating technique to coat objects with a thin layer of metal, typically nickel or copper.

1. Barrel Plating Process

The Barrel Plater’s primary duty is to operate the barrel plating machines and ensure the electroplating process is carried out efficiently and according to established quality standards.

- Load and unload barrels containing metal parts into the plating machine.

- Monitor and adjust the plating parameters, including temperature, current density, and chemical composition of the plating solution.

- Unload plated parts and inspect for defects and proper coating thickness.

2. Quality Control

Ensuring the quality of plated parts is crucial, and the Barrel Plater is responsible for:

- Performing regular quality checks on plated parts, including thickness testing, visual inspection, and adherence tests.

- Maintaining accurate records of plating parameters and quality control results.

- Identifying and resolving any issues that may affect the quality of the plating process.

3. Equipment Maintenance

To ensure smooth and efficient operations, the Barrel Plater is expected to:

- Perform regular maintenance and cleaning of plating machines, including the cleaning of barrels, racks, and anodes.

- Troubleshoot and resolve any technical issues with the plating equipment.

- Follow established safety protocols and maintain a clean and organized work area.

4. Environmental Compliance

As electroplating involves the use of chemicals and hazardous materials, the Barrel Plater must:

- Follow environmental regulations and waste disposal procedures.

- Maintain a safe and healthy work environment by wearing appropriate protective gear and adhering to safety rules.

- Dispose of spent plating solutions and hazardous waste in accordance with established protocols.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Barrel Plater interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Barrel Plater position. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website to learn about their products, services, and history.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in electroplating.

2. Practice Answering Common Interview Questions

Anticipating and preparing for common interview questions can help you feel more confident and articulate during the interview. Consider these questions:

- Tell me about your experience with barrel plating.

- How do you ensure the quality of plated parts?

- What is your safety record like?

- How do you handle environmental compliance in your work?

3. Be Enthusiastic and Professional

A positive attitude and professional demeanor can leave a lasting impression on interviewers. Show your enthusiasm for the role and the field of electroplating.

- Dress appropriately for the interview.

- Arrive on time and be prepared to discuss your qualifications.

- Maintain eye contact, speak clearly, and demonstrate active listening skills.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. It also gives you an opportunity to clarify any aspects of the role.

- What are the company’s growth plans for the future?

- What opportunities are there for professional development?

- What are the company’s safety protocols?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Plater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!