Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Barrel Roller Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Barrel Roller Operator so you can tailor your answers to impress potential employers.

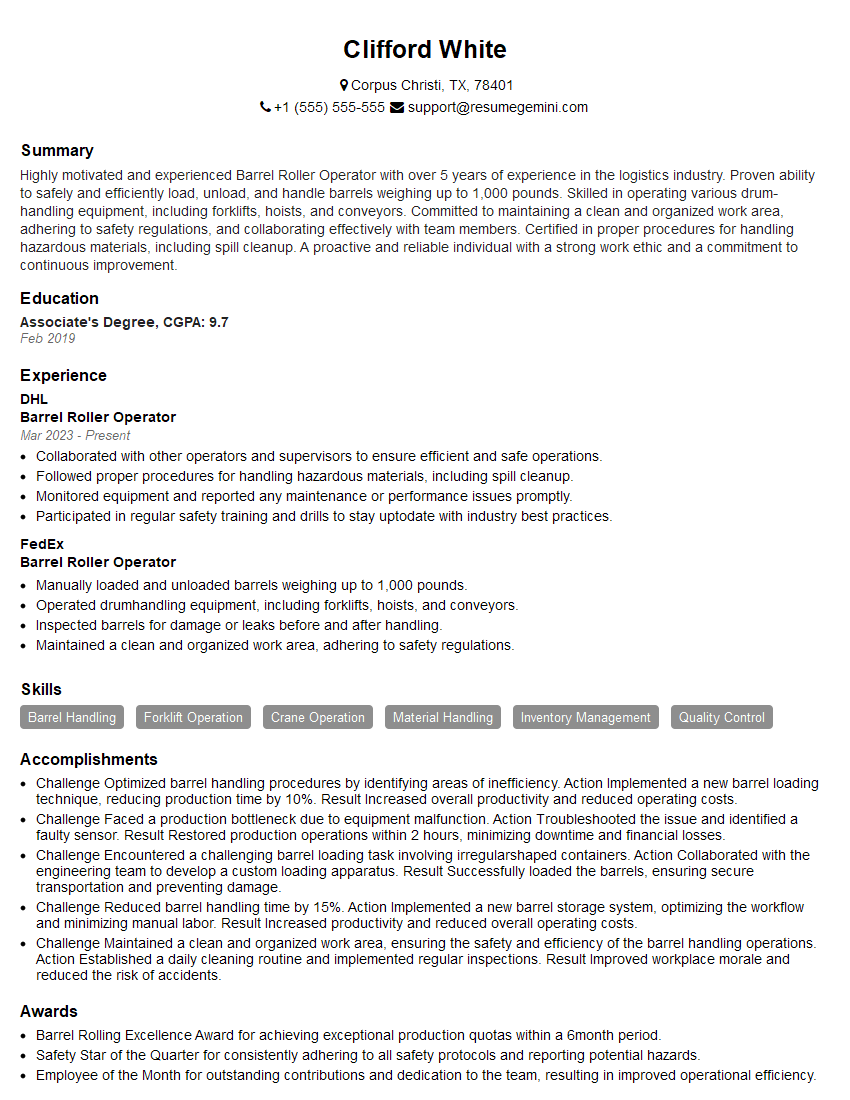

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Roller Operator

1. Describe the process of loading and unloading barrels onto the barrel roller.

To load barrels onto the barrel roller, I first ensure the machine is turned off and the area is clear of any obstacles. Then, using a forklift or other appropriate equipment, I carefully lift the barrels and place them securely onto the conveyor rollers.

To unload barrels, I reverse the process, operating the conveyor rollers to move the barrels to the desired location and using the forklift or other equipment to remove them from the machine. I always ensure that all barrels are handled safely and securely throughout the process to prevent damage or injury.

2. What are the different types of barrels that you have handled using a barrel roller, and what are their unique requirements?

Metal barrels

- These barrels are typically made of steel or aluminum and are used to store various liquids, chemicals, and other materials.

- When handling metal barrels, I ensure they are securely fastened to the conveyor and take extra care to avoid damage to the barrels or the machine.

Plastic barrels

- Plastic barrels are lightweight and resistant to corrosion, making them suitable for storing food, chemicals, and other sensitive materials.

- I handle plastic barrels with care to prevent punctures or cracks that could compromise their integrity.

Fiberboard barrels

- These barrels are made of corrugated fiberboard and are commonly used for packaging dry goods and other non-hazardous materials.

- I handle fiberboard barrels gently to avoid tearing or damaging the material.

3. How do you ensure the safety of yourself and others when operating a barrel roller?

- I always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots.

- I thoroughly inspect the machine and work area before each use to identify any potential hazards.

- I operate the barrel roller according to the manufacturer’s instructions and avoid overloading or exceeding the machine’s capacity.

- I am aware of my surroundings and maintain a safe distance from moving parts.

- I never attempt to repair or adjust the machine while it is in operation.

4. What are some common troubleshooting techniques for barrel roller malfunctions?

- If the conveyor rollers are not moving, I check the power supply and ensure that the machine is properly plugged in.

- If the barrels are not loading or unloading smoothly, I inspect the conveyor rollers for any obstructions or damage.

- If the machine is making unusual noises or vibrations, I stop operation immediately and contact a qualified technician for assistance.

5. How do you maintain and clean a barrel roller to ensure optimal performance?

- After each use, I clean the conveyor rollers and other surfaces to remove any debris or residue.

- I regularly lubricate the moving parts according to the manufacturer’s instructions.

- I inspect the machine for any signs of wear or damage and make necessary repairs or replacements as needed.

6. How do you calculate the weight of a barrel based on its dimensions and material?

To calculate the weight of a barrel, I use the formula: weight = volume × density.

First, I determine the volume of the barrel using the appropriate formula for its shape (e.g., cylindrical formula for a cylindrical barrel).

Then, I find the density of the barrel material from a reference table or the manufacturer’s specifications.

Finally, I multiply the volume by the density to obtain the weight of the barrel.

7. What are the different types of conveyors used in barrel rolling systems, and what are their advantages and disadvantages?

Gravity conveyors

- Advantages: Simple design, low maintenance, no power required.

- Disadvantages: Requires a sloped surface, limited to downhill movement.

Powered conveyors

- Advantages: Can handle heavier loads, can move barrels in any direction.

- Disadvantages: More complex design, higher maintenance requirements, power consumption.

Roller conveyors

- Advantages: Smooth and efficient movement, can handle various barrel sizes.

- Disadvantages: Can be more expensive than other types of conveyors.

8. How do you handle oversized or irregularly shaped barrels on a barrel roller?

- For oversized barrels, I use special attachments or extensions to the conveyor rollers to accommodate the extra width or length.

- For irregularly shaped barrels, I carefully adjust the conveyor rollers to ensure they support the barrel securely and prevent it from rolling or falling off.

9. What are the environmental considerations when operating a barrel roller?

- I minimize noise pollution by operating the machine during designated hours and using noise-dampening measures.

- I properly dispose of any waste materials generated during operation, such as oil, grease, or cleaning solvents.

- I ensure the machine is energy-efficient and maintained to reduce its environmental impact.

10. How do you stay updated on the latest advancements and best practices in barrel rolling technology?

- I attend industry conferences and workshops to learn about new developments and innovations.

- I read trade publications and online resources to stay abreast of emerging technologies and trends.

- I consult with manufacturers and suppliers to gain insights into the latest equipment and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Roller Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Roller Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Roller Operators are responsible for operating and maintaining barrel rolling machines in a variety of settings, including manufacturing, warehousing, recycling, and waste management. The primary function of these machines is to rotate barrels, drums, and other cylindrical containers to facilitate various processes such as mixing, blending, coating, cleaning, and drying. Key responsibilities typically include:

1. Machine Operation

Ensuring the safe and efficient operation of barrel rolling machines, following established procedures and protocols.

- Loading and unloading barrels onto the machine

- Setting and adjusting machine parameters (e.g., rotation speed, duration)

2. Quality Control

Monitoring the rolling process to ensure that it meets specified quality standards.

- Inspecting barrels for any defects or damage

- Ensuring that the rotation speed and duration are appropriate for the specific materials

3. Maintenance and Troubleshooting

Performing routine maintenance tasks to ensure the smooth functioning of the machine, and addressing any technical issues that arise.

- Lubricating moving parts

- Diagnosing and repairing minor malfunctions

4. Safety Compliance

Adhering to all safety regulations and procedures while operating the machine, to prevent accidents and injuries.

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures when performing maintenance

Interview Tips

To ace the interview for a Barrel Roller Operator position, it is essential to demonstrate your technical proficiency, attention to detail, and strong safety awareness. Here are some valuable tips to help you prepare and perform your best:

1. Highlight Your Technical Skills

Emphasize your experience in operating barrel rolling machines, including different models and capacities. Mention any specific techniques or procedures you are familiar with, and provide examples of how you have successfully handled various challenges.

- Example: “I have extensive experience operating a range of barrel rolling machines, including horizontal and vertical models, with capacities from 50 to 500 gallons. I am also proficient in handling different types of barrels made from materials such as steel, plastic, and fiber.”

2. Showcase Your Quality Control Mindset

Highlight your commitment to maintaining high-quality standards in your work. Give examples of how you ensure that barrels are properly rolled and meet the desired specifications. Emphasize your attention to detail and your ability to identify and address any potential issues.

- Example: “In my previous role, I implemented a rigorous inspection process to ensure that all barrels were thoroughly inspected before and after the rolling process. I also developed a detailed checklist to track quality parameters and identify any defects or irregularities.”

3. Emphasize Your Safety Awareness

Stress your strong understanding of safety protocols and your commitment to following them consistently. Describe your experience with PPE, lockout/tagout procedures, and any other relevant safety measures. Highlight how you prioritize safety in your work environment.

- Example: “Safety is paramount to me, and I always adhere to established safety procedures without compromise. I am fully trained in the use of PPE, including respirators, gloves, and safety glasses. I also regularly participate in safety training programs to stay up-to-date with best practices.”

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that demonstrate your knowledge and skills. Some typical questions you may encounter include:

- Can you describe your experience in operating barrel rolling machines?

- How do you ensure the quality of the rolling process?

- What safety measures do you take when operating barrel rolling machines?

- How do you handle unexpected situations or malfunctions during the rolling process?

5. Practice Your Responses

To build confidence and fluency in your answers, practice delivering them aloud. Seek feedback from a friend, family member, or career counselor to improve your communication and presentation skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Roller Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.