Are you gearing up for a career in Base Draw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Base Draw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

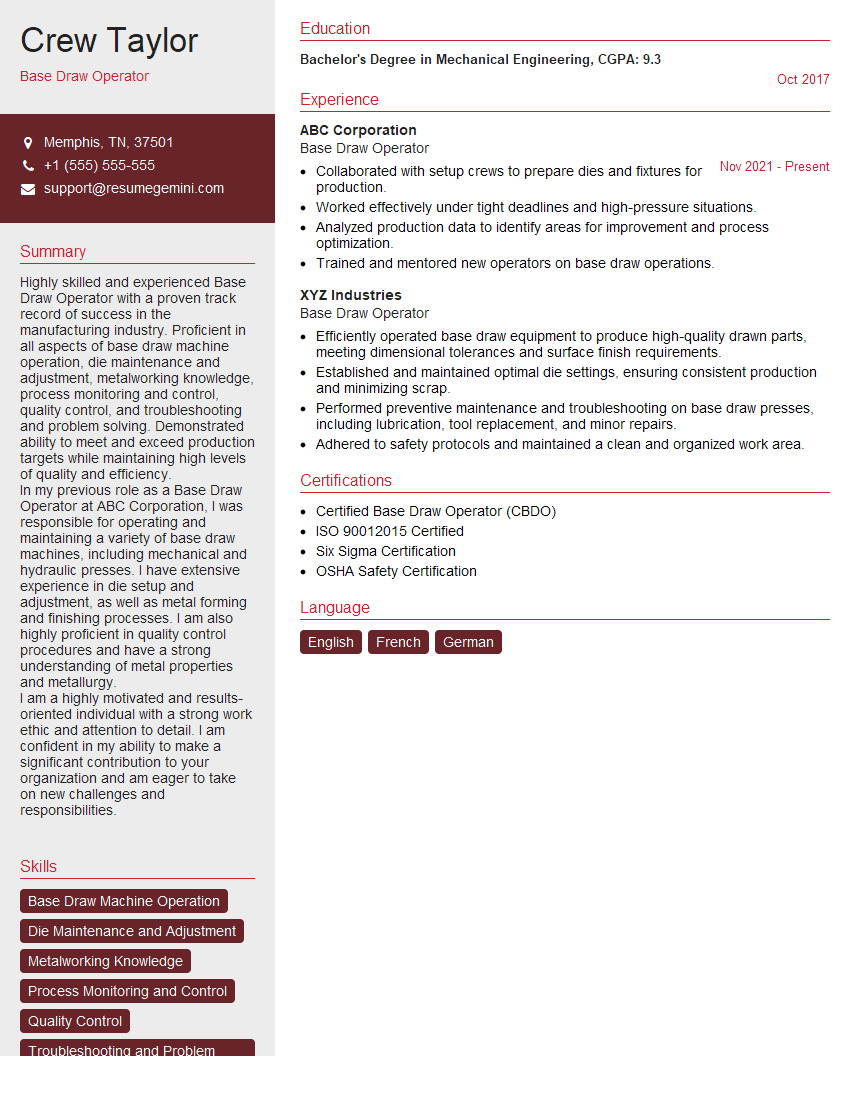

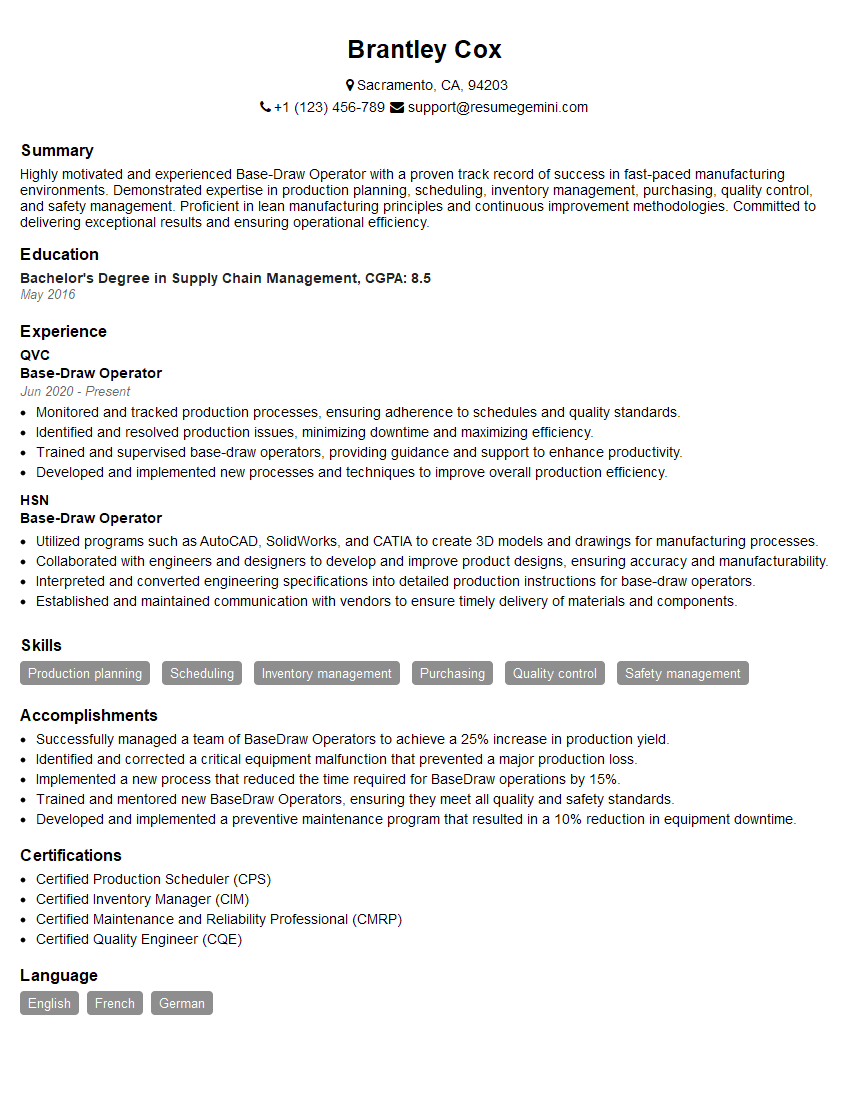

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Base Draw Operator

1. What are the responsibilities of a Base Draw Operator?

As a Base Draw Operator, I would be responsible for:

- Loading steel rods onto the cold draw machine

- Adjusting the machine to the correct settings

- Monitoring the machine during operation

- Troubleshooting any issues that may arise

- Ensuring that the drawn wire meets the required specifications

- Maintaining a clean and safe work area

2. What is the difference between wire drawing and cold drawing?

Wire Drawing

- Wire drawing is the process of reducing the diameter of wire by pulling it through a series of dies.

- The wire is drawn through the dies at a high speed, which causes it to stretch and become thinner.

- Wire drawing can be used to produce wire of various diameters and strengths.

Cold Drawing

- Cold drawing is a type of wire drawing that is done at room temperature.

- Cold drawing produces wire with a smoother surface finish and closer tolerances than wire that is drawn at high temperatures.

3. What are the different types of dies used in cold drawing?

The different types of dies used in cold drawing include:

- Single-hole dies

- Multi-hole dies

- Carbide dies

- Diamond dies

4. What are the factors that affect the quality of the drawn wire?

The factors that affect the quality of the drawn wire include:

- The quality of the raw material

- The condition of the dies

- The drawing speed

- The drawing temperature

- The lubrication

5. What are the safety precautions that must be taken when operating a cold draw machine?

The safety precautions that must be taken when operating a cold draw machine include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs

- Keeping the work area clean and free of debris

- Being aware of the moving parts of the machine

- Never operating the machine when it is not properly guarded

- Following all of the manufacturer’s instructions

6. What is the role of the die lubricant in cold drawing?

The role of the die lubricant in cold drawing is to:

- Reduce friction between the wire and the die

- Cool the wire and the die

- Prevent the wire from sticking to the die

- Improve the surface finish of the wire

7. How do you troubleshoot a cold draw machine that is not producing wire to the desired specifications?

To troubleshoot a cold draw machine that is not producing wire to the desired specifications, I would:

- Check the raw material to ensure that it is of good quality

- Check the condition of the dies and replace them if necessary

- Check the drawing speed and adjust it as necessary

- Check the drawing temperature and adjust it as necessary

- Check the lubrication and apply more lubricant if necessary

8. What is your experience with maintaining and repairing cold draw machines?

I have experience with maintaining and repairing cold draw machines, including:

- Lubricating the machine

- Cleaning the machine

- Adjusting the machine

- Replacing the dies

- Troubleshooting the machine

9. What are your strengths and weaknesses as a Base Draw Operator?

My strengths as a Base Draw Operator include:

- My attention to detail

- My ability to troubleshoot problems

- My ability to work independently

- My willingness to learn new things

My weaknesses as a Base Draw Operator include:

- My lack of experience with certain types of cold draw machines

- My lack of experience with certain types of wire

10. Why are you interested in working as a Base Draw Operator?

I am interested in working as a Base Draw Operator because I am passionate about manufacturing and I am eager to learn more about the cold drawing process. I am also confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Base Draw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Base Draw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Base Draw Operator plays a pivotal role in the production of printed materials by operating a high-speed base draw machine. Their primary responsibilities involve ensuring the smooth functioning of the machine, monitoring production quality, and adhering to safety protocols.

1. Machine Operation and Maintenance

The operator is responsible for the efficient operation and maintenance of the base draw machine. This includes:

- Setting up the machine according to production specifications

- Monitoring machine parameters and making necessary adjustments to maintain optimal performance

- Performing routine maintenance and troubleshooting to prevent breakdowns

- Coordinating with the maintenance team for major repairs and upgrades

2. Production Monitoring and Quality Control

Ensuring the quality of printed materials is a crucial aspect of the role. The operator is responsible for:

- Inspecting printed materials for defects and non-conformities

- Adjusting machine settings and materials as needed to meet quality standards

- Maintaining accurate records of production output and quality control checks

- Reporting any anomalies or quality issues to supervisors

3. Safety Compliance and Training

The operator is accountable for maintaining a safe work environment and adhering to safety regulations. This includes:

- Following established safety procedures and wearing appropriate personal protective equipment (PPE)

- Identifying and mitigating potential hazards in the work area

- Participating in safety training programs and staying updated on industry best practices

- Assisting in training new operators and maintaining a safe and productive work atmosphere

4. Communication and Teamwork

Effective communication and teamwork are essential for the operator’s success. They are responsible for:

- Communicating with supervisors, colleagues, and customers to coordinate production activities

- Participating in team meetings and sharing knowledge to improve processes

- Providing feedback on machine performance and suggesting improvements

- Collaborating with other departments to ensure seamless production flow

Interview Tips

To ace your Base Draw Operator interview, it’s crucial to prepare thoroughly and showcase your skills and knowledge. Here are some tips to help you stand out:

1. Research the Company and Role

Demonstrate your enthusiasm by researching the company’s values, operations, and the specific role you’re applying for. Highlight how your experience aligns with their needs.

2. Practice Your Technical Skills

Be prepared to discuss your technical proficiency in operating base draw machines. Practice explaining machine setup, maintenance procedures, and troubleshooting techniques.

3. Emphasize Quality Control and Safety

Emphasize your commitment to producing high-quality printed materials and maintaining a safe work environment. Share examples of how you have implemented quality control measures and adhered to safety protocols.

4. Highlight Your Communication and Teamwork Skills

Demonstrate your ability to communicate effectively and work collaboratively in a team environment. Provide examples of how you have successfully communicated with colleagues, resolved conflicts, and contributed to a positive work atmosphere.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive and enthusiastic demeanor throughout the interview. Show that you are eager to join their team and contribute to their success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Base Draw Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.