Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Base Loader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

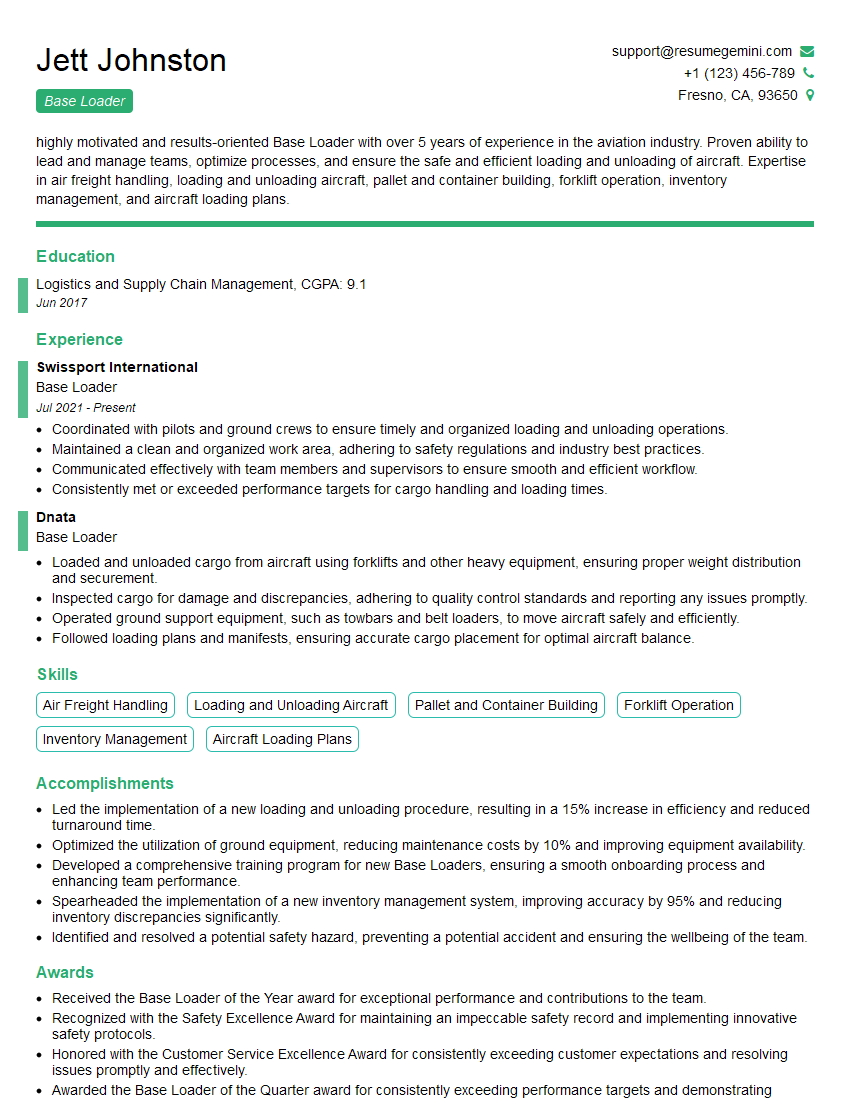

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Base Loader

1. Describe the process of loading and unloading bulk materials using a base loader?

The process of loading and unloading bulk materials using a base loader involves several key steps:

- Positioning the loader: The base loader is positioned near the loading or unloading area, ensuring stability and proper alignment.

- Preparing the material: The material to be handled is prepared by loosening and aerating it, if necessary, to facilitate loading.

- Loading: The loader’s bucket is extended into the material pile. The bucket is filled by scooping and lifting the material. The bucket is then raised and transported to the loading area.

- Unloading: At the unloading area, the bucket is positioned over the designated location. The bucket is tilted to discharge the material, which is then spread or distributed as required.

- Cleaning the bucket: After unloading, the bucket is cleaned to remove any residual material. This ensures that the bucket is ready for subsequent loading cycles.

2. What are the different types of base loaders and their applications?

There are several types of base loaders, each designed for specific applications:

Front-end loaders

- Articulated loaders: Highly maneuverable, suitable for tight spaces and uneven terrain.

- Industrial loaders: Heavy-duty loaders with high lifting capacities, used in construction and mining.

Side-loaders

- Reach stackers: Specialized loaders used in container handling at ports and terminals.

- Lift trucks: Designed for handling palletized materials in warehouses and distribution centers.

3. What are the safety precautions that must be taken when operating a base loader?

Operating a base loader safely requires adherence to the following precautions:

- Pre-operation checks: Inspecting the loader for any damage or malfunctions before use.

- Proper loading and unloading techniques: Ensuring the bucket is properly filled and emptied to prevent spillage and accidents.

- Load stability: Distributing the load evenly within the bucket to maintain stability.

- Visibility: Maintaining clear visibility around the loader, using mirrors or cameras if necessary.

- Protective gear: Wearing appropriate safety gear, such as a hard hat, safety glasses, and high-visibility clothing.

4. How do you ensure efficient and productive operation of a base loader?

Optimizing the operation of a base loader involves several strategies:

- Proper maintenance: Regularly servicing and maintaining the loader to ensure it operates at peak performance.

- Operator training: Providing comprehensive training to ensure operators are proficient in handling the loader safely and efficiently.

- Efficient loading and unloading techniques: Using proper techniques to minimize cycle times and maximize productivity.

- Job planning: Optimizing loading and unloading sequences to reduce downtime and increase efficiency.

5. How do you troubleshoot common problems that may arise while operating a base loader?

Troubleshooting common base loader issues requires a systematic approach:

- Identifying the problem: Pinpointing the specific issue based on symptoms, error codes, or observations.

- Consulting manuals and resources: Referring to technical manuals or online resources for diagnostic guidance.

- Conducting visual inspections: Checking for any visible damage, leaks, or loose connections.

- Using diagnostic tools: Employing diagnostic tools to identify specific faults or component failures.

- Taking corrective actions: Resolving the problem by repairing or replacing faulty components, adjusting settings, or implementing software updates.

6. Describe the role of preventive maintenance in ensuring the longevity of a base loader?

Preventive maintenance plays a crucial role in extending the lifespan of a base loader:

- Regular inspections: Conducting periodic inspections to identify potential issues and address them promptly.

- Scheduled maintenance: Adhering to a maintenance schedule to replace fluids, filters, and other components at recommended intervals.

- Lubrication: Regularly lubricating moving parts to minimize friction and wear.

- Record keeping: Maintaining detailed records of maintenance activities to track the loader’s condition and history.

7. How do you assess the productivity of a base loader operation?

Evaluating the productivity of a base loader operation involves analyzing key metrics:

- Cycle time: Measuring the average time taken to complete a loading or unloading cycle.

- Throughput: Calculating the amount of material handled per unit of time.

- Equipment utilization: Determining the percentage of time the loader is actively engaged in loading or unloading.

- Operator efficiency: Assessing the operator’s proficiency in operating the loader smoothly and efficiently.

8. What are the different types of attachments that can be used with a base loader?

Various attachments enhance the versatility of a base loader:

- Buckets: Different bucket sizes and designs for specific materials and applications.

- Forks: For handling palletized materials.

- Clamps: For handling irregular or bulky objects.

- Grapples: For handling loose materials such as scrap metal or logs.

- Snow blades and brooms: For snow removal and cleaning.

9. How do you determine the best type of base loader for a specific application?

Selecting the appropriate base loader for a task depends on several factors:

- Material characteristics: The type of material being handled, its density, and flowability.

- Loading and unloading requirements: The height and distance of loading and unloading points.

- Environmental conditions: The terrain, weather conditions, and space constraints at the operation site.

- Budget and availability: The cost and availability of different loader models and attachments.

10. What are the emerging trends in base loader technology?

The base loader industry is evolving with advancements in technology:

- Electric base loaders: Environmentally friendly options with zero emissions.

- Automated base loaders: Utilizing sensors and AI to optimize loading and unloading processes.

- Integrated loader management systems: Providing real-time monitoring and data analysis for improved efficiency.

- Remote control and telematics: Allowing operators to control and monitor loaders remotely.

- Virtual reality and augmented reality training: Enhancing operator training and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Base Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Base Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Base Loaders are responsible for loading aircraft and are also responsible for unloading cargo as well.

1. Loading and Unloading Aircraft

Base Loaders are responsible for safely following the proper procedures to load materials into aircraft cargo holds. Additionally, Base Loaders are also responsible for unloading materials from cargo holds of aircrafts in a timely and efficient manner.

- Inspect aircraft to ensure it is ready for loading

- Operate and use ground support equipment (GSE)

- Unload cargo from aircraft

2. Inspecting Cargo

Base Loaders are also responsible for inspecting cargo to ensure that it is safe to be loaded or unloaded from aircraft. This includes checking for any hazardous materials, proper labelling, and that the cargo is properly secured.

- Inspect cargo for damage

- Check for proper labeling and documentation

- Verify cargo is properly secured

3. Operating Ground Support Equipment

Base Loaders are also required to operate ground support equipment, such as forklifts, cranes, and conveyor belts, to load and unload cargo. They should also be able to move cargo safely and accurately, using the necessary equipment for each task.

- Operate forklifts

- Operate cranes

- Operate conveyor belts

4. Maintaining Safety

Base Loaders should be able to work in a fast-paced environment and be able to follow safety regulations and procedures. They should also be comfortable working in all types of weather conditions.

- Adhere to safety regulations

- Wear appropriate safety gear

- Follow proper loading and unloading procedures

Interview Tips

Here are some interview tips to help you ace the interview for a Base Loader position.

1. Research the company and the industry

Take some time to learn about the company you’re applying to and the industry they operate in. This will show the interviewer that you’re interested in the position and that you’ve taken the time to prepare for the interview.

- Visit the company’s website

- Read articles about the company and the industry

- Talk to people who work in the industry

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to think about how you would answer these questions and practice your answers out loud.

- Think about your strengths and weaknesses

- Prepare examples of your experience that demonstrate your skills

- Practice your answers with a friend or family member

3. Dress appropriately

First impressions matter, so it’s important to dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for. You should also make sure to arrive on time for your interview.

- Dress professionally

- Arrive on time

- Be polite and respectful

4. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident and honest, and let your personality shine through.

- Be confident

- Be honest

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Base Loader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.