Are you gearing up for an interview for a Basting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Basting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

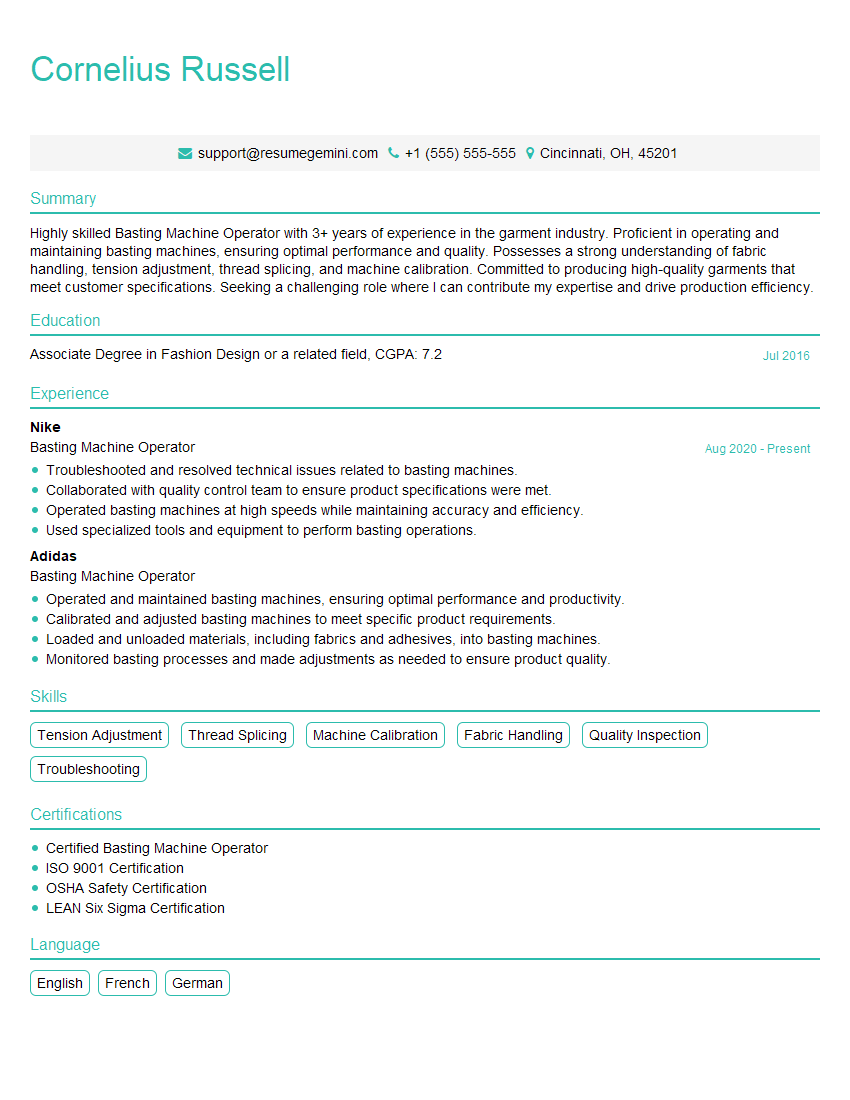

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Basting Machine Operator

1. Tell me about your experience as a Basting Machine Operator?

During my tenure as a Basting Machine Operator, I have consistently exceeded production targets while maintaining high quality standards. I have a proven ability to operate various basting machines, including manual and automated models, with expertise in handling different fabrics and thread types.

2. What are the key technical skills required to be a successful Basting Machine Operator?

Technical Skills

- Proficient in operating and troubleshooting basting machines

- Knowledge of different fabrics and their appropriate basting techniques

Communication Skills

- Ability to communicate effectively with supervisors and team members

- Excellent attention to detail and a keen eye for quality

3. How do you ensure the quality of your work as a Basting Machine Operator?

To ensure the quality of my work, I adhere to strict quality control procedures. I meticulously inspect each garment before and after basting to identify any potential defects. I also use precision measuring tools to ensure consistent and accurate stitching. Furthermore, I regularly calibrate and maintain my machines to minimize errors and optimize performance.

4. What types of fabrics have you worked with and how do you adjust your basting technique accordingly?

I have experience working with a wide range of fabrics, including delicate silks, intricate laces, and heavy-duty canvas. I adjust my basting technique based on the fabric’s properties. For delicate fabrics, I use fine needles and lightweight thread to avoid damaging the material. For heavy-duty fabrics, I employ heavier needles and thicker thread to ensure secure stitching.

5. How do you handle and resolve machine malfunctions and production issues as a Basting Machine Operator?

When faced with machine malfunctions, I quickly troubleshoot the problem by following standard operating procedures and referring to technical manuals. I am proficient in performing basic maintenance tasks, such as replacing needles, cleaning components, and adjusting tension settings. If the issue persists, I promptly report it to my supervisor for further troubleshooting.

6. Describe your experience in meeting production targets and deadlines as a Basting Machine Operator?

Throughout my career, I have consistently met and exceeded production targets while maintaining high-quality standards. I effectively manage my time and prioritize tasks to ensure efficient and timely completion. I also actively seek opportunities to streamline processes and improve productivity.

7. What are some of the safety protocols you follow as a Basting Machine Operator?

- Always wear appropriate safety gear, including gloves and safety glasses

- Maintain a clean and organized work area

- Inspect machines regularly for potential hazards

- Report any safety concerns to supervisors immediately

8. How do you stay up-to-date with the latest basting techniques and industry best practices?

To stay current with the latest basting techniques and industry best practices, I regularly attend industry workshops and seminars. I also read trade publications and consult with experienced colleagues to gain insights and knowledge. Additionally, I actively seek opportunities to learn about new technologies and advancements in the field.

9. What are your strengths and weaknesses as a Basting Machine Operator?

Strengths

- Exceptional attention to detail and accuracy

- Strong technical skills and proficiency in operating various basting machines

- Proven ability to meet and exceed production targets

Weaknesses

- Limited experience with certain specialized fabrics

- Still developing my troubleshooting skills for complex machine malfunctions

10. Why do you believe you are the ideal candidate for this Basting Machine Operator position?

I am confident that I am the ideal candidate for this Basting Machine Operator position due to my proven track record of success in the field. My strong technical skills, attention to quality, and commitment to meeting production targets make me a valuable asset to any organization. I am eager to contribute my expertise and dedication to your team and am confident that I can exceed your expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Basting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Basting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Basting Machine Operator is responsible for operating and maintaining basting machines in a manufacturing environment. This role plays a critical part in ensuring the smooth production of high-quality garments.

1. Machine Operation

The primary responsibility of a Basting Machine Operator is to skillfully operate basting machines. This includes:

- Setting up the machine according to specific garment specifications.

- Loading fabric and materials into the machine.

- Adjusting machine settings to ensure optimal basting quality.

- Monitoring the machine’s operation and making necessary adjustments.

2. Quality Control

Ensuring the quality of the basted garments is crucial. Basting Machine Operators are responsible for:

- Inspecting garments for defects and inconsistencies.

- Identifying and correcting any errors in the basting process.

- Maintaining high standards of accuracy and precision.

3. Machine Maintenance

To ensure the efficient operation of the basting machines, operators must perform regular maintenance tasks, such as:

- Cleaning and lubricating the machine.

- Inspecting for wear and tear.

- Replacing worn parts as needed.

- Reporting any maintenance issues to supervisors.

4. Safety Compliance

Adhering to safety protocols is paramount in this role. Basting Machine Operators must:

- Wear appropriate safety gear, including gloves and protective eyewear.

- Follow established safety procedures.

- Report any unsafe conditions or practices.

Interview Tips

To ace the interview for a Basting Machine Operator position, it’s essential to prepare thoroughly. Here are some valuable tips to help you succeed:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you’re applying for. This will help you understand the company’s culture, values, and the expectations for the position.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This includes questions about your experience, skills, and why you’re interested in the role. Consider using the STAR method to structure your answers, providing specific examples to support your claims.

3. Highlight Your Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Describe your proficiency in operating basting machines, your attention to detail, and your ability to work independently and as part of a team. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show your passion for the role and your eagerness to contribute to the company. Be respectful and professional in your interactions with the interviewer.

5. Ask Thoughtful Questions

Ask insightful questions at the end of the interview to demonstrate your engagement and interest in the role. This is an opportunity to clarify any details about the position or the company, and it shows that you’re genuinely interested in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Basting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.