Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Batch and Furnace Manager position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

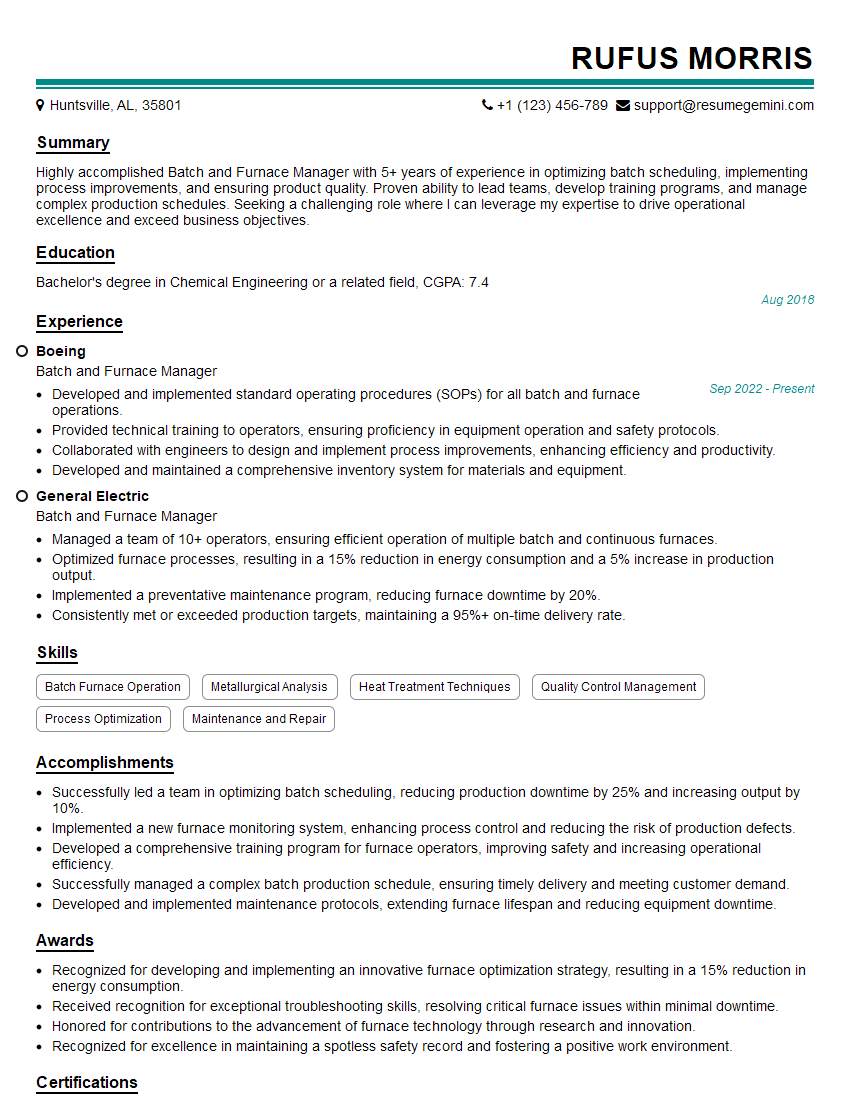

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch and Furnace Manager

1. What are the key performance indicators (KPIs) that you track for batch and furnace operations? How do you monitor and optimize these KPIs?

- Production output: Measure the quantity of products produced per batch or furnace cycle.

- Product quality: Monitor the adherence to specifications, defects, and customer complaints.

- Cycle time: Track the time taken to complete a batch or furnace run, including setup, processing, and cooling.

- Energy consumption: Monitor the amount of energy used during the processes to identify areas for improvement.

- Equipment availability: Ensure furnaces and batch systems are operational and regularly maintained.

- Optimize through continuous monitoring and data analysis, identifying trends, implementing lean principles, and making adjustments to processes and equipment.

2. Describe the different types of batch and furnace systems you have experience with. What are their advantages and limitations?

Batch Systems

- Advantages: Flexibility, cost-effective for small production runs.

- Limitations: Less efficient, higher labor costs.

Continuous Systems

- Advantages: Higher efficiency, lower labor costs.

- Limitations: Less flexible, higher capital costs.

Tunnel Kilns

- Advantages: Continuous operation, high production rates.

- Limitations: Complex design, high maintenance costs.

Shuttle Kilns

- Advantages: Flexibility, ability to handle large batches.

- Limitations: Lower efficiency compared to continuous systems.

3. What are the safety protocols and regulations that you are familiar with for batch and furnace operations? How do you ensure compliance?

- OSHA regulations for handling hazardous materials, equipment safety, and personal protective equipment.

- NFPA standards for fire prevention and protection in industrial settings.

- Environmental regulations for air quality, waste disposal, and hazardous materials.

- Maintain compliance through regular safety inspections, training programs, and adherence to standard operating procedures.

4. How do you manage a team of operators and technicians in a batch and furnace environment?

- Provide clear instructions, training, and supervision to ensure safe and efficient operations.

- Motivate and empower the team through recognition, rewards, and opportunities for growth.

- Foster a positive and collaborative work environment, encouraging open communication and teamwork.

- Monitor performance, provide feedback, and implement training programs to enhance skills and knowledge.

5. What are some common problems that can occur in batch and furnace operations, and how do you troubleshoot and resolve them?

- Equipment breakdowns: Diagnose the issue, identify faulty components, and perform repairs or replacements.

- Product quality issues: Analyze the process parameters, adjust settings, or modify raw materials to correct defects.

- Inefficient cycle times: Optimize process flows, reduce bottlenecks, and implement lean manufacturing techniques.

- Energy waste: Conduct energy audits, identify areas for improvement, and implement energy-saving measures.

6. How do you stay up-to-date with advances in batch and furnace technology?

- Attend industry conferences, seminars, and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Pursue continuing education or certification programs.

7. How do you prioritize and manage multiple projects and responsibilities in a fast-paced batch and furnace environment?

- Establish clear priorities based on deadlines, customer requirements, and business objectives.

- Create a structured schedule and allocate resources effectively.

- Delegate tasks to team members and provide support and guidance.

- Monitor progress regularly and make adjustments as needed to ensure timely completion.

8. How do you manage inventory and ensure the availability of raw materials and consumables for batch and furnace operations?

- Establish inventory levels based on production schedules and lead times.

- Implement inventory control systems to track stock levels and reorder points.

- Coordinate with suppliers to ensure timely delivery of materials.

- Monitor inventory turnover and identify opportunities for optimization.

9. How do you maintain and calibrate equipment in batch and furnace operations to ensure accuracy and efficiency?

- Develop a comprehensive maintenance schedule based on manufacturer recommendations and equipment usage.

- Conduct regular inspections and tests to identify potential issues.

- Calibrate equipment using certified instruments and procedures.

- Document all maintenance and calibration activities for traceability and compliance.

10. How do you measure and improve the quality of products produced in batch and furnace operations?

- Establish quality standards based on customer requirements and industry specifications.

- Conduct regular inspections and testing to assess product quality.

- Analyze quality data to identify trends and areas for improvement.

- Implement process improvements to reduce defects and enhance product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch and Furnace Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch and Furnace Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Batch and Furnace Manager plays a crucial role in ensuring the efficient and safe operation of batch and furnace systems within a manufacturing environment. Their primary responsibilities encompass:

1. Production Management

Overseeing the planning, scheduling, and coordination of batch and furnace production to meet customer requirements and production targets.

- Developing and implementing production schedules and work orders.

- Allocating resources and materials to ensure production efficiency.

2. Furnace and Equipment Operation

Managing the operation and maintenance of batch and furnace systems, ensuring their optimal performance and safety.

- Monitoring and adjusting furnace parameters such as temperature, atmosphere, and cycle times.

- Performing routine maintenance and repairs on equipment to minimize downtime.

3. Quality Control

Maintaining product quality and consistency by implementing quality control measures throughout the production process.

- Inspecting products at various stages of production to identify and rectify defects.

- Conducting regular quality audits and implementing corrective actions as needed.

4. Team Management

Leading and motivating a team of production personnel, providing training and guidance to enhance their skills and productivity.

- Assigning tasks and responsibilities to team members.

- Evaluating performance and providing feedback.

5. Safety Management

Ensuring compliance with all safety regulations and implementing safety protocols to prevent accidents and injuries.

- Conducting safety inspections and maintaining a safe work environment.

- Training employees on safety procedures and providing personal protective equipment.

Interview Tips

To enhance your chances of success in the Batch and Furnace Manager interview, consider the following tips:

1. Research the Company

Familiarize yourself with the company’s background, mission, and industry standing. Knowledge of their products, services, and operations will demonstrate your interest and preparation.

- Visit the company’s website and social media platforms.

- Read industry news and articles related to the company.

2. Practice Common Interview Questions

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses?”

- Rehearse your answers out loud to build confidence and fluency.

- Consider how your experiences and skills align with the job responsibilities.

3. Highlight Your Technical Expertise

Emphasize your technical knowledge and experience in batch and furnace operations. Provide specific examples of how you have optimized production processes, improved safety measures, or resolved production issues.

- Quantify your achievements with measurable results whenever possible.

- Explain the theories and principles behind your decision-making and problem-solving abilities.

4. Showcase Your Leadership and Communication Skills

The Batch and Furnace Manager role requires strong leadership and communication abilities. Highlight your experience in managing teams, motivating employees, and fostering a positive work environment.

- Describe situations where you successfully led a team to achieve a challenging goal.

- Provide examples of effective communication techniques you have used to build relationships and resolve conflicts.

5. Ask Thoughtful Questions

The interview is also an opportunity for you to learn more about the company and the position. Prepare a list of thoughtful questions to ask the interviewer, demonstrating your engagement and interest.

- Inquire about the company’s growth plans and technological advancements.

- Ask about the team you would be working with and the company culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batch and Furnace Manager interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.