Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Batch Dumper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

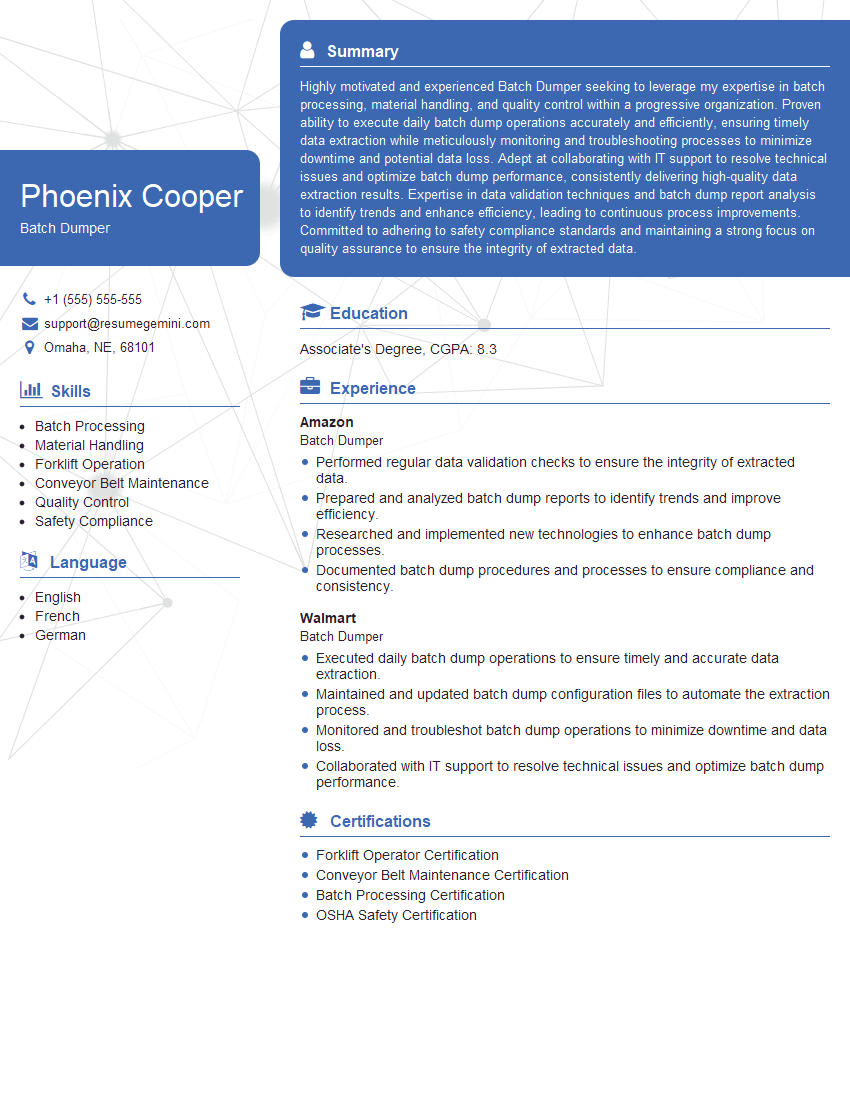

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch Dumper

1. Describe the key responsibilities of a Batch Dumper?

The primary responsibilities of a Batch Dumper typically include:

- Operating and maintaining batch dumping equipment, such as dump trucks, conveyor belts, and excavators

- Loading, transporting, and depositing bulk materials according to specified instructions

- Monitoring equipment performance, identifying potential issues, and performing basic maintenance tasks

- Ensuring compliance with safety regulations and environmental standards

- Working as part of a team to achieve production targets and maintain a safe and efficient work environment

2. What are the different types of batch dumping equipment and their applications?

Dump Trucks

- Transporting loose materials such as soil, gravel, and construction waste

- Equipped with hydraulically operated beds that tilt to discharge materials

Conveyor Belts

- Conveying bulk materials over long distances or different elevations

- Composed of motorized rollers and a continuous belt that carries materials

Excavators

- Digging, lifting, and loading materials using hydraulically powered arms and buckets

- Used in construction, mining, and waste management operations

3. How do you ensure the proper loading and distribution of materials during batch dumping operations?

To ensure proper loading and distribution of materials during batch dumping operations, I follow these steps:

- Verifying load specifications and ensuring the equipment is suitable for the material being handled

- Loading materials carefully to prevent damage to equipment or spillage

- Distributing materials evenly within the dump area to avoid overloading or uneven settling

- Monitoring load levels and adjusting operations as needed to maintain stability and prevent spills

4. Describe the safety precautions you take when operating batch dumping equipment?

When operating batch dumping equipment, I prioritize safety by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and high-visibility vests

- Inspecting equipment thoroughly before each use to identify potential hazards

- Maintaining a safe distance from other equipment and personnel

- Following established operating procedures and avoiding risky maneuvers

- Reporting any safety concerns or incidents promptly to supervisors

5. How do you handle potential equipment malfunctions or breakdowns during batch dumping operations?

In the event of potential equipment malfunctions or breakdowns during batch dumping operations, I follow these steps:

- Immediately ceasing operations and isolating the affected equipment

- Identifying the source of the malfunction or breakdown through visual inspection and diagnostic checks

- Attempting basic repairs or troubleshooting if possible and authorized

- Contacting maintenance personnel or supervisors for assistance with more complex issues

- Documenting the incident and any actions taken for future reference

6. How do you maintain and service batch dumping equipment to ensure optimal performance?

To maintain and service batch dumping equipment for optimal performance, I perform the following tasks:

- Regularly inspecting equipment for wear, damage, or leaks

- Cleaning and lubricating moving parts to prevent excessive friction and premature failure

- Replacing worn or damaged components as needed

- Following manufacturer’s guidelines for scheduled maintenance intervals

- Keeping a maintenance log to track repairs and replacements

7. What techniques do you use to improve efficiency and productivity in batch dumping operations?

To improve efficiency and productivity in batch dumping operations, I employ the following techniques:

- Optimizing loading and unloading sequences to minimize equipment downtime

- Coordinating with other operators to ensure smooth material flow

- Using technology, such as GPS tracking and automated controls, to enhance efficiency

- Suggesting process improvements and implementing best practices

- Continuously seeking opportunities to streamline operations

8. How do you stay up-to-date with industry best practices and advancements in batch dumping techniques?

To stay up-to-date with industry best practices and advancements in batch dumping techniques, I engage in the following activities:

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussions

- Consulting with manufacturers and equipment suppliers

- Seeking feedback from experienced colleagues and supervisors

9. How do you manage working in a physically demanding and potentially hazardous environment as a Batch Dumper?

To manage working in a physically demanding and potentially hazardous environment as a Batch Dumper, I adhere to the following practices:

- Maintaining physical fitness through regular exercise and proper nutrition

- Using proper lifting techniques and avoiding overexertion

- Wearing appropriate PPE and following safety protocols

- Staying alert and aware of potential hazards

- Taking breaks and hydrating regularly to prevent fatigue and heat-related illnesses

10. What motivates you to work as a Batch Dumper?

I am motivated to work as a Batch Dumper because I enjoy the physical challenges and the opportunity to contribute to large-scale projects. I find satisfaction in operating heavy equipment and making a tangible difference in construction or mining operations. Additionally, I value the team-oriented environment and the opportunity to learn from experienced professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch Dumper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch Dumper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Batch Dumpers are responsible for performing various tasks in a manufacturing or industrial setting, involving the handling and movement of materials.

1. Loading and Unloading Materials

They are responsible for loading and unloading raw materials, finished products, or other items into and out of dumpers, bins, or other containers.

- Operate forklifts, cranes, or other equipment to move heavy materials.

- Ensure proper loading and unloading techniques to prevent damage to materials or equipment.

2. Monitoring Batch Processes

Batch Dumpers monitor batch processes to ensure they are operating efficiently and safely.

- Monitor equipment such as mixers, conveyors, and pumps to ensure proper functioning.

- Adjust process parameters as needed to maintain optimal conditions.

3. Maintaining Equipment

They perform basic maintenance and cleaning tasks on equipment used in the batch dumping process.

- Clean and lubricate equipment to prevent breakdowns.

- Perform minor repairs and troubleshooting to ensure equipment is in good working order.

4. Following Safety Procedures

Batch Dumpers are responsible for following all safety procedures and regulations in the workplace.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats.

- Follow lockout/tagout procedures to prevent accidents during equipment maintenance.

Interview Tips

Preparing for a Batch Dumper interview requires thorough research about the role and the company. Here are some effective interview preparation tips and hacks to help candidates ace their interview.

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, values, and the specific responsibilities of the Batch Dumper role. This knowledge demonstrates your interest and enthusiasm for the position.

- Visit the company website to gather information about their products, services, and recent developments.

- Read industry publications and articles to stay updated on trends and best practices in batch dumping.

2. Practice Common Interview Questions

Anticipate and prepare answers to common interview questions. Practice delivering clear and concise responses that highlight your relevant skills and experience.

- Tell me about yourself and your background in batch dumping.

- Describe your experience in operating and maintaining equipment used in batch dumping processes.

- How do you ensure that batch processes are operating efficiently and safely?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the Batch Dumper role. Tailor your responses to match the job requirements.

- Quantify your accomplishments and provide specific examples of your contributions to previous roles.

- Use action verbs and industry-specific terminology to demonstrate your knowledge and expertise.

4. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your interest in the position and the company.

- What are the key performance indicators (KPIs) for a successful Batch Dumper in this role?

- Can you describe the team structure and reporting relationships for this position?

- What are the company’s plans for future growth and development in the batch dumping area?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Batch Dumper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.