Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Batch Heat Treat Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

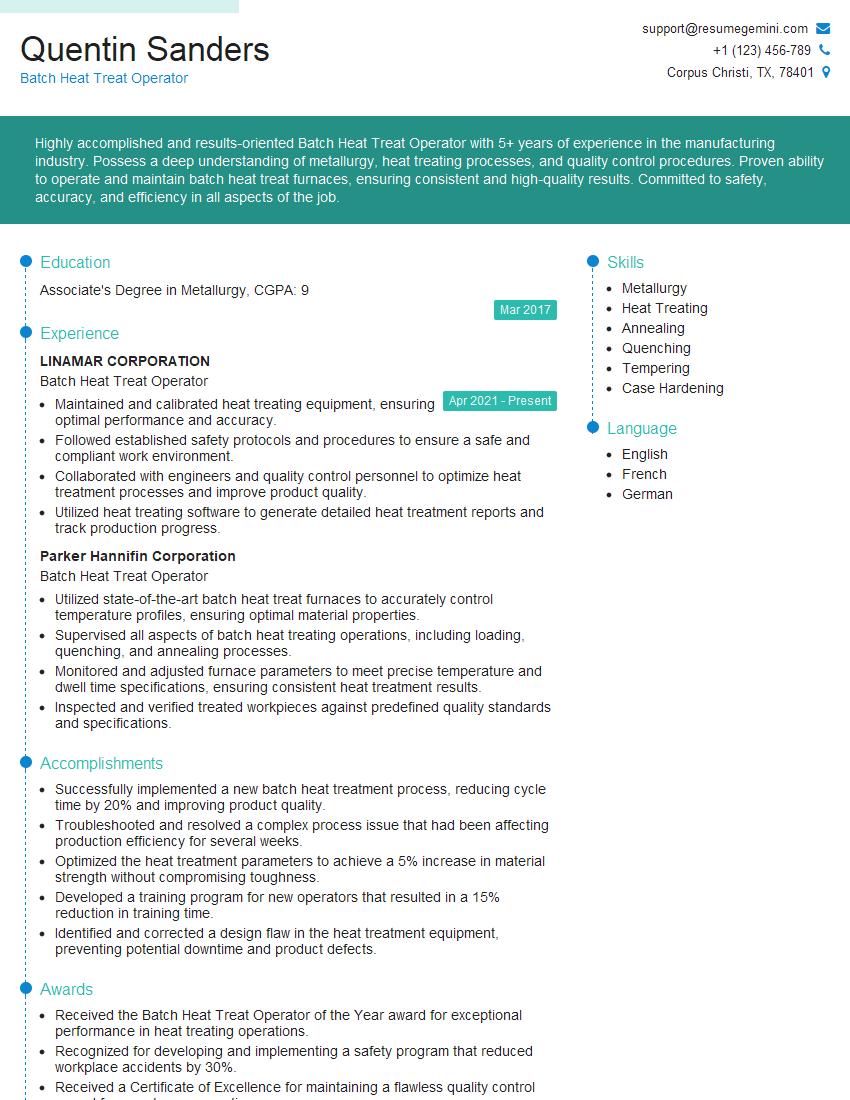

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch Heat Treat Operator

1. Describe the process of heat treating a batch of metal components.

- Inspect the components to ensure they meet specifications.

- Load the components into the heat treating furnace.

- Set the furnace temperature and cycle time according to the material and desired properties.

- Monitor the temperature and time using instruments.

- Quench the components using the appropriate method.

- Temper the components to achieve the desired hardness and strength.

- Inspect the treated components to ensure they meet specifications.

2. What are the different types of heat treatment processes?

Annealing

- Softens the material by heating and cooling slowly.

- Reduces internal stresses and improves ductility.

Hardening

- Increases the hardness and strength of the material.

- Heats the material to a high temperature and then quenches it rapidly.

Tempering

- Reduces the brittleness of hardened steel.

- Heats the material to a lower temperature and then cools it slowly.

3. What are the factors that affect the outcome of a heat treatment process?

- Type of material being treated

- Temperature and time of the heat treatment

- Quenching method

- Tempering temperature and time

- Equipment and process control

4. How do you ensure the quality of heat treated components?

- Follow established procedures and specifications.

- Use calibrated instruments and equipment.

- Inspect components at various stages of the process.

- Document the heat treatment parameters and results.

- Conduct hardness and other tests to verify the properties of the components.

5. What is the importance of proper heat treatment for metal components?

- Enhances the mechanical properties of the components.

- Improves the durability and performance of the components.

- Reduces the risk of component failure.

- Extends the lifespan of the components.

6. Describe the safety procedures that must be followed when operating heat treating equipment.

- Wear appropriate personal protective equipment.

- Follow lockout/tagout procedures before servicing equipment.

- Handle hot materials with caution and use proper lifting techniques.

- Be aware of potential hazards such as burns, fumes, and explosions.

- Receive training on the safe operation of heat treating equipment.

7. How do you troubleshoot common problems that arise during heat treatment?

- Identify the problem and its potential causes.

- Check the equipment and instruments for any malfunctions.

- Review the heat treatment parameters and make adjustments as needed.

- Inspect the components for any defects or damage.

- Consult with a supervisor or technical expert for assistance.

8. What are the latest advancements in heat treatment technology?

- Automated heat treatment systems

- Computer-controlled process optimization

- Advanced quenching techniques

- Non-destructive testing methods

- Development of new heat treatable materials

9. How do you stay up-to-date with the latest industry trends and best practices in heat treatment?

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Participate in online forums and discussions.

- Network with other professionals in the field.

- Take advantage of training and development opportunities.

10. Why are you interested in this Batch Heat Treat Operator position?

- Interested in the technical aspects of heat treatment and its impact on material properties.

- Desire to contribute to the production of high-quality heat treated components.

- Excited about the opportunity to work with advanced equipment and technologies.

- Willing to follow safety procedures and maintain a clean and organized work area.

- Eager to learn and grow as a Batch Heat Treat Operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch Heat Treat Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch Heat Treat Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Batch Heat Treat Operators are responsible for the operation and maintenance of batch heat treat furnaces. They monitor and control the temperature, atmosphere, and other process parameters to ensure that the heat treatment process meets the required specifications. Batch Heat Treat Operators also load and unload workpieces, and perform quality control checks to ensure that the finished products meet the customer’s requirements.

1. Furnace Operation

Operate and maintain batch heat treat furnaces, including gas-fired, electric-resistance, and vacuum furnaces.

- Monitor and control furnace temperature, atmosphere, and other process parameters to ensure that the heat treatment process meets the required specifications.

- Load and unload workpieces into and out of the furnace.

- Perform quality control checks on finished products to ensure that they meet the customer’s requirements.

2. Process Control

Monitor and control the heat treatment process to ensure that it meets the required specifications.

- Monitor and record process parameters, such as temperature, atmosphere, and time.

- Make adjustments to the process parameters as needed to ensure that the heat treatment process meets the required specifications.

- Troubleshoot and resolve process problems.

3. Equipment Maintenance

Perform preventive maintenance on heat treat furnaces and related equipment.

- Inspect furnaces and related equipment for wear and tear.

- Perform routine maintenance tasks, such as cleaning, lubrication, and calibration.

- Troubleshoot and repair equipment problems.

4. Safety

Follow all safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

Preparing for an interview for a Batch Heat Treat Operator position requires a well-rounded approach that encompasses both technical knowledge and professional presentation. Here are some tips to help you ace your interview:

1. Research the Company

Before the interview, take the time to research the company you are applying to. This will give you a better understanding of their business, their culture, and their specific needs. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the position.

- Visit the company’s website to learn about their products, services, and history.

- Read industry news and articles to stay up-to-date on the latest trends.

- Connect with current or former employees on LinkedIn to gain insights into the company culture.

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare a brief introduction of yourself, including your relevant skills and experience.

- Practice answering questions about your experience with batch heat treat furnaces.

- Think about questions you might have for the interviewer.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Avoid wearing jeans, t-shirts, or other casual clothing.

- Choose clothing that is comfortable and allows you to move around easily.

- Consider wearing a suit or dress pants and a button-down shirt.

4. Be Enthusiastic and Positive

Hiring managers are looking for candidates who are enthusiastic and positive about their work. Make sure you convey your passion for the heat treat industry and your desire to learn and grow.

- Smile and make eye contact with the interviewer.

- Be polite and respectful, even if you don’t agree with everything the interviewer says.

- Show your enthusiasm for the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Batch Heat Treat Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.