Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Batch Still Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

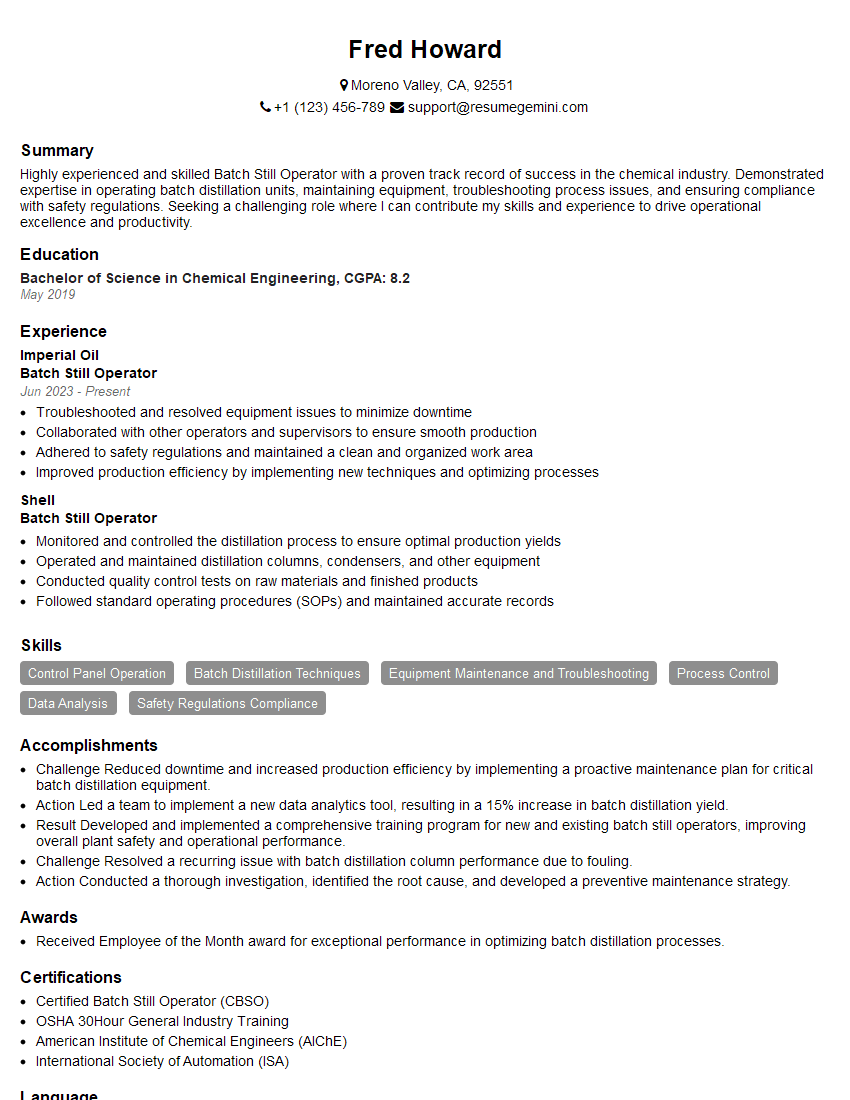

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch Still Operator

1. Explain the distillation process used in batch stills.

The batch distillation process in stills involves several steps:

- Charging: The still is filled with the liquid mixture to be separated.

- Heating: The mixture is heated to its boiling point, causing the more volatile components to evaporate.

- Vaporization: The vapors rise and condense in a condenser, forming the distillate.

- Collection: The distillate is collected in a separate container.

- Runoff: The remaining liquid in the still, known as the bottoms, is discharged.

2. Describe the key operating parameters to monitor during batch distillation and explain their significance.

Temperature:

- Monitors the vaporization rate and ensures efficient separation.

Pressure:

- Controls the boiling point of the mixture and influences distillation efficiency.

Reflux ratio:

- Determines the amount of vapor returned to the still, affecting the purity of the distillate.

Flow rate:

- Manages the rate of liquid entering and exiting the still, ensuring optimal separation.

3. How do you ensure product quality and consistency in batch distillation?

Ensuring product quality and consistency in batch distillation requires:

- Strict adherence to operating parameters: Maintaining optimal temperature, pressure, and flow rates.

- Regular sampling and testing: Monitoring the composition of the distillate and bottoms to ensure specification compliance.

- Equipment calibration and maintenance: Ensuring accurate readings and optimal performance of instruments.

- Good manufacturing practices (GMPs): Implementing protocols to prevent contamination and ensure product safety.

4. Explain the safety precautions that must be observed when operating a batch still.

Safety precautions for batch still operation include:

- Personal protective equipment (PPE): Wearing appropriate safety glasses, gloves, and lab coat.

- Fire safety: Keeping the area free of flammable materials and having fire extinguishers readily available.

- Pressure relief systems: Ensuring that the still is equipped with pressure relief valves to prevent explosions.

- Proper ventilation: Maintaining adequate ventilation to remove vapors and prevent inhalation hazards.

- Spill containment: Having procedures in place to contain and clean up spills.

5. Describe the troubleshooting steps you would take if the batch still is not producing the desired distillate purity.

- Check operating parameters: Verify that temperature, pressure, and flow rates are within specifications.

- Inspect equipment: Look for leaks, blockages, or malfunctions that may affect separation efficiency.

- Adjust reflux ratio: Increase or decrease the reflux ratio to improve purity or yield.

- Analyze distillate samples: Determine if impurities are present and identify their source.

- Consult with technical experts: Seek guidance from engineers or chemists to optimize distillation conditions.

6. How do you calculate the theoretical and actual yields of a batch distillation process?

Theoretical Yield:

- Based on the initial composition of the mixture and the vapor-liquid equilibrium data.

- Calculated using equations of state or simulation software.

Actual Yield:

- Measured after the distillation process is complete.

- Determined by weighing or measuring the volume of the distillate and bottoms.

7. Explain the advantages and disadvantages of using a batch still compared to a continuous still.

Batch Still Advantages:

- Flexibility: Can handle various batch sizes and compositions.

- Low capital cost: Typically less expensive than continuous stills.

Batch Still Disadvantages:

- Lower efficiency: Produces smaller yields compared to continuous stills.

- Batch process: Requires more labor and time for cleaning and setup.

8. How do you optimize the energy consumption of a batch still?

- Insulate the still: Reduce heat loss to the surroundings.

- Optimize heating: Use efficient heating methods and temperature control systems.

- Control reflux ratio: Minimize energy consumption while maintaining desired purity.

- Consider heat recovery systems: Utilize heat exchangers to recover energy from the process.

9. What methods can be used to improve the separation efficiency of a batch still?

- Multi-stage distillation: Divide the distillation into multiple stages for better separation.

- Vacuum distillation: Reduce pressure to lower boiling points and improve volatility differences.

- Azeotropic distillation: Add an entrainer to modify the vapor-liquid equilibrium.

- Chromatographic distillation: Use a packed column to achieve high-resolution separations.

10. How do you maintain the batch still to ensure optimal performance and longevity?

- Regular cleaning and inspection: Remove contaminants and identify potential issues.

- Equipment calibration: Ensure accurate readings and control of operating parameters.

- Preventive maintenance: Schedule routine inspections and repairs to prevent breakdowns.

- Spare parts management: Keep critical spare parts on hand to minimize downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Batch Still Operator is a highly skilled professional who is responsible for operating and maintaining a batch still. They are responsible for ensuring that the still is operating safely and efficiently, and that the products produced meet the required specifications.

1. Operation of the batch still

The Batch Still Operator is responsible for operating the batch still, which is a complex and delicate piece of equipment. They must be able to start up, shut down, and adjust the still to produce the desired product.

- Starting up and shutting down the still

- Adjusting the still to produce the desired product

- Monitoring the still’s operation

- Taking corrective action if the still’s operation deviates from the desired parameters

2. Maintenance of the batch still

The Batch Still Operator is also responsible for maintaining the batch still. They must be able to identify and repair any problems that may occur, and ensure that the still is always operating in a safe and efficient manner.

- Inspecting the still for any damage or wear and tear

- Replacing any worn or damaged parts

- Lubricating the still’s moving parts

- Cleaning the still

3. Quality control

The Batch Still Operator is responsible for ensuring that the products produced by the still meet the required specifications. They must be able to test the products and make adjustments to the still’s operation as necessary.

- Testing the products produced by the still

- Making adjustments to the still’s operation as necessary

- Maintaining records of the products produced by the still

4. Safety

The Batch Still Operator is responsible for ensuring that the still is operated in a safe manner. They must be familiar with all safety regulations and procedures, and must be able to identify and mitigate any potential hazards.

- Following all safety regulations and procedures

- Identifying and mitigating any potential hazards

- Responding to emergencies

Interview Tips

Preparing for a Batch Still Operator interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and will also give you a better idea of what the job entails.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write out your answers to common interview questions

- Practice answering these questions out loud

- Get feedback from a friend or family member

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Batch Still Operator. Be prepared to talk about your skills and experience in detail, and be sure to highlight any accomplishments that you have made.

- Bring a copy of your resume to the interview

- Be prepared to talk about your experience in detail

- Highlight any accomplishments that you have made

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in business attire

- Arrive on time for your interview

- Be polite and respectful to the interviewer

5. Be confident and enthusiastic

Confidence and enthusiasm are key when it comes to interviewing. Believe in yourself and your abilities, and let the interviewer know that you are excited about the opportunity to work for their company.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Smile and be enthusiastic

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batch Still Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.