Are you gearing up for a career in Batch Weigher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Batch Weigher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

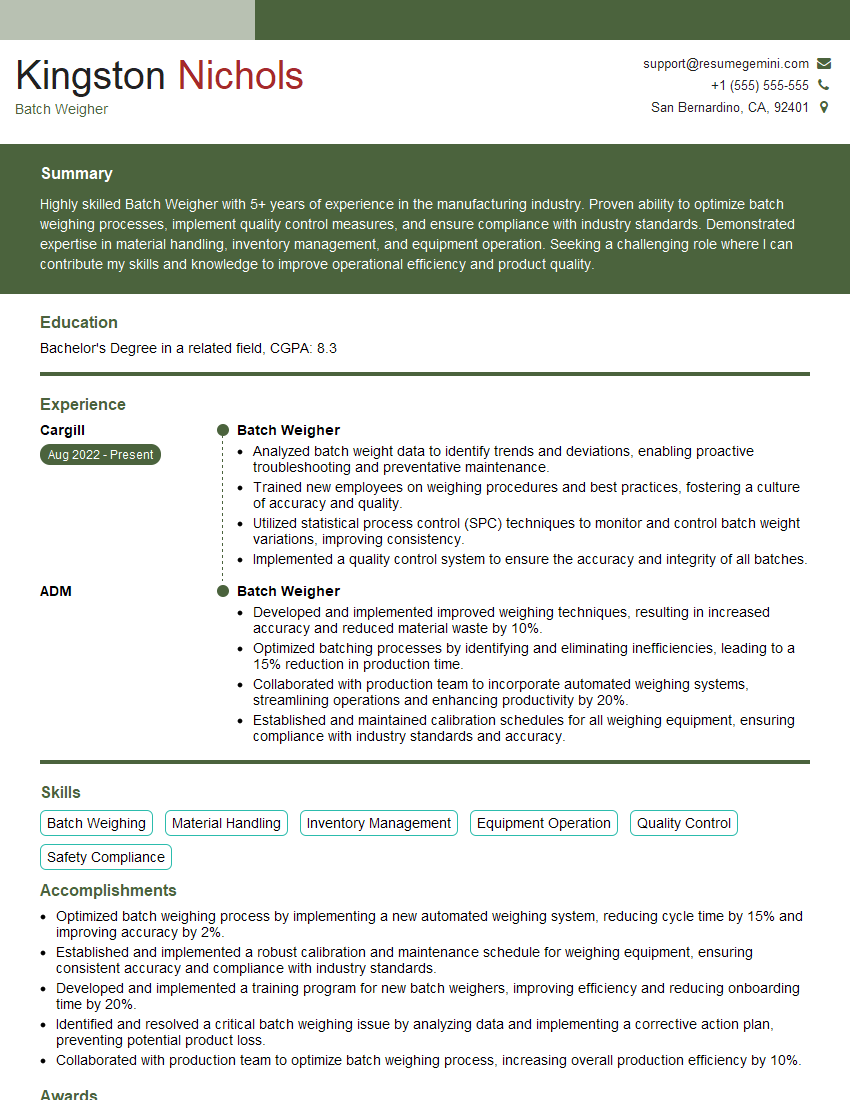

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch Weigher

1. What are the calibration verification interval requirements of the scale?

- Per OIML R76-1:2006, the calibration verification interval shall not exceed 2 years.

- The calibration verification interval may be reduced if required by the application or by the competent authority.

2. What are the different types of batch weighers?

Weigh hoppers

- Suspended weigh hopper

- Floor-mounted weigh hopper

Belt conveyors

- Single-belt conveyor

- Multi-belt conveyor

Loss-in-weight feeders

3. What are the advantages and disadvantages of using a weight hopper batch weigher?

- Advantages: High accuracy, low maintenance, easy to operate

- Disadvantages: Slow operation, limited capacity

4. What are the advantages and disadvantages of using a belt conveyor batch weigher?

- Advantages: High capacity, continuous operation, low maintenance

- Disadvantages: Lower accuracy than weight hopper batch weighers

5. What are the advantages and disadvantages of using a loss-in-weight feeder batch weigher?

- Advantages: High accuracy, continuous operation, low maintenance

- Disadvantages: Complex design, higher cost

6. What are the factors to consider when selecting a batch weigher?

- Capacity

- Accuracy

- Speed

- Cost

- Maintenance

7. How do you calibrate a batch weigher?

- Place a known weight on the scale.

- Adjust the scale’s calibration until the display matches the weight of the known weight.

- Repeat steps 1 and 2 for several different weights.

8. How do you troubleshoot a batch weigher that is not weighing accurately?

- Check the scale’s calibration.

- Check the scale’s load cell.

- Check the scale’s wiring.

- Check the scale’s software.

9. What are the safety precautions that should be taken when operating a batch weigher?

- Do not overload the scale.

- Do not place the scale on an uneven surface.

- Do not use the scale in a hazardous area.

- Do not attempt to repair the scale yourself.

10. What are the latest trends in batch weighing technology?

- Increased use of automation

- Development of more accurate and reliable sensors

- Integration of batch weighers with other plant equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Batch Weigher is responsible for weighing and measuring ingredients for various production processes. They ensure accuracy and consistency in the production process.

1. Weighing and Measuring Ingredients

Accurately weigh and measure all ingredients according to the given specifications.

- Use a variety of weighing equipment, such as scales, balances, and dispensers.

- Record weights and measurements and maintain detailed records for quality control purposes.

2. Maintaining Equipment

Maintain and calibrate weighing equipment to ensure accuracy and precision.

- Regularly clean and inspect equipment to prevent errors and ensure optimal performance.

- Report any equipment malfunctions or issues promptly to the appropriate personnel.

3. Adhering to Safety Regulations

Follow all safety regulations and procedures to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat.

- Handle and store chemicals and hazardous materials safely.

4. Teamwork and Collaboration

Work effectively with other team members to ensure efficient and accurate production.

- Communicate clearly and effectively with colleagues, supervisors, and other departments.

- Assist in maintaining a clean and organized work area.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Batch Weigher position:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and products. Understand the specific requirements of the Batch Weigher role and align your skills and experience accordingly.

- Visit the company’s website and social media pages.

- Read industry publications and articles related to batch weighing.

2. Highlight Your Skills and Experience

Emphasize your proficiency in weighing and measuring techniques, your attention to detail, and your ability to work accurately and efficiently. Share specific examples of your accomplishments in previous roles.

- Quantify your accomplishments whenever possible, using metrics and data.

- Explain how your skills and experience align with the job requirements.

3. Prepare for Technical Questions

Be prepared to answer questions related to batch weighing operations, equipment maintenance, and safety procedures. Review common weighing techniques, calibration procedures, and industry regulations.

- Practice answering technical questions in a clear and concise manner.

- Demonstrate your knowledge of industry best practices and standards.

4. Show Your Enthusiasm and Interest

Express your genuine interest in the Batch Weigher position and the company. Ask thoughtful questions about the role, the team, and the company’s goals. Your enthusiasm and passion for the field can make a positive impression.

- Be confident and articulate your interest in the role.

- Ask questions that demonstrate your engagement and curiosity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batch Weigher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!