Are you gearing up for an interview for a Batcher Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Batcher Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

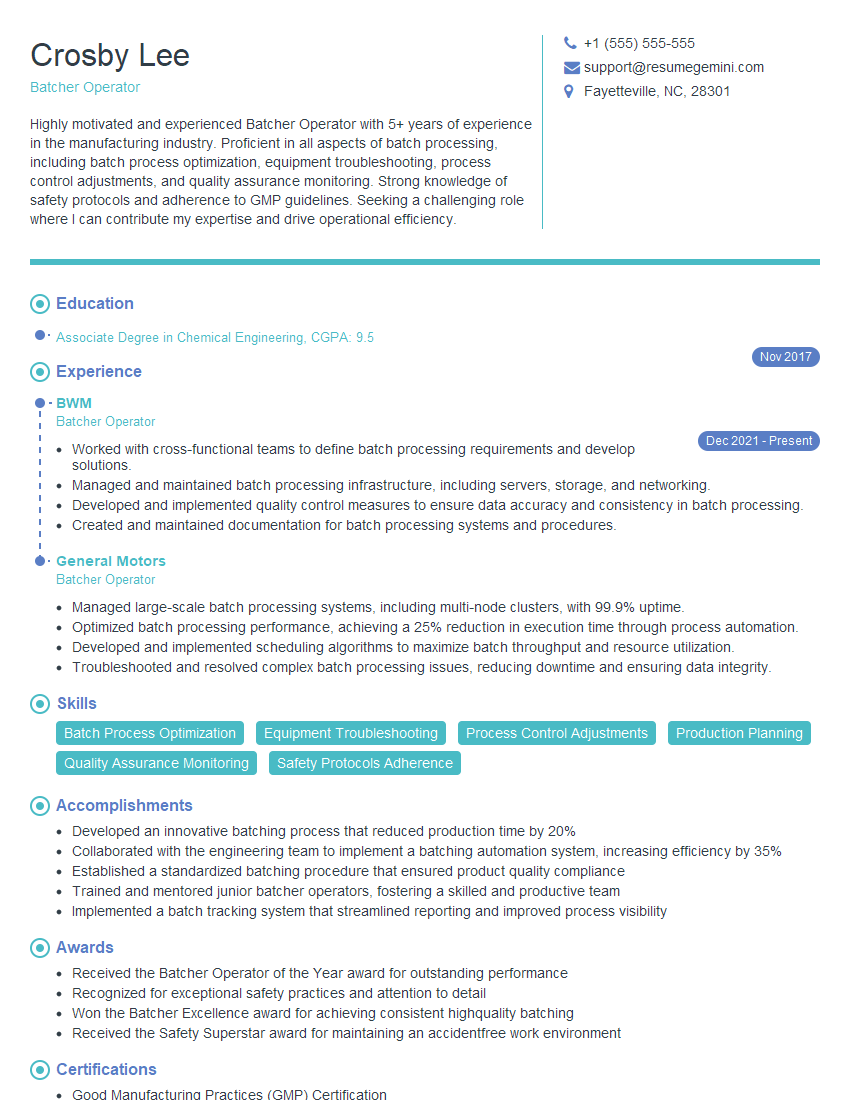

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batcher Operator

1. Describe the main responsibilities of a Batcher Operator.

- Manage the production process of a batch plant, ensuring the production of high-quality concrete.

- Operate and monitor batching equipment, including mixers, weigh scales, and conveyors.

- Weigh and measure ingredients accurately according to specified batch recipes.

- Maintain a clean and organized work area, adhering to safety protocols.

- Troubleshoot and resolve technical issues related to batching operations.

2. What is the difference between dry batching and wet batching?

Dry Batching

- Involves weighing and mixing the dry ingredients (cement, sand, and aggregate) before adding water.

- The dry mix is then transported to the job site and mixed with water at the point of placement.

- Suitable for small projects or remote locations where water is not readily available.

Wet Batching

- All ingredients, including water, are weighed and mixed on-site.

- Produces a more consistent and homogenous concrete mix.

- Requires a steady supply of water and a suitable mixing facility on-site.

3. What are the key parameters to control in batching concrete?

- Water-cement ratio: Determines the strength and durability of the concrete.

- Aggregate gradation: Ensures a dense and workable concrete mix.

- Air content: Improves the concrete’s resistance to freeze-thaw cycles.

- Slump: Measures the workability and consistency of the concrete.

- Temperature: Affects the setting time and strength development of the concrete.

4. How do you calibrate a batching scale?

- Use certified calibration weights to verify the accuracy of the scale.

- Zero the scale and apply known weights to different points on the platform.

- Adjust the scale settings to ensure precise measurements across the entire weighing range.

- Document the calibration process and maintain records for traceability.

5. What are the common causes of batching errors?

- Inaccurate weighing of ingredients due to scale malfunctions or human error.

- Variations in the moisture content of aggregates.

- Improper batching sequence or incorrect batch recipes.

- Equipment failures or mechanical issues.

- Lack of proper training or supervision.

6. How do you troubleshoot a concrete mixer that is not mixing properly?

- Check if the mixer blades are rotating correctly and making contact with the concrete.

- Inspect the condition of the blades and replace any worn or damaged ones.

- Ensure that the concrete is within the specified slump range for proper mixing.

- Verify that the mixer is operating at the correct speed and for the appropriate duration.

- Inspect the mixer drum for any obstructions or excessive wear.

7. What are the safety precautions to take when operating a batch plant?

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and a dust mask.

- Follow established lockout/tagout procedures when performing maintenance or repairs.

- Stay clear of moving machinery and conveyor belts.

- Be aware of potential hazards such as electrical hazards, dust inhalation, and moving vehicles.

- Receive proper training and adhere to all safety protocols.

8. How do you maintain a batch plant to ensure optimal performance?

- Conduct regular inspections and maintenance checks on all equipment, including mixers, scales, and conveyors.

- Lubricate moving parts and replace worn or damaged components.

- Calibrate scales and ensure accurate measurements.

- Clean and maintain the batch plant area, including removing dust and debris.

- Follow manufacturer’s recommendations and consult with experts for technical support.

9. What are the different types of concrete additives and their uses?

- Water reducers: Increase concrete fluidity, allowing for reduced water content and improved strength.

- Accelerators: Speed up the setting and hardening process of concrete.

- Retarders: Slow down the setting time of concrete, extending its workability.

- Air-entraining agents: Introduce tiny air bubbles into the concrete, improving its resistance to freeze-thaw cycles.

- Fiber reinforcements: Enhance the tensile strength and toughness of concrete.

10. How do you handle customer inquiries or complaints related to concrete quality?

- Respond promptly and professionally to all inquiries.

- Gather relevant information about the concrete mix, batching process, and delivery conditions.

- Conduct an investigation to determine the cause of the issue.

- Provide a clear explanation of the findings to the customer.

- Offer solutions or recommendations to address the concerns and prevent recurrence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batcher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batcher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Batcher Operators play a crucial role in the manufacturing industry, ensuring the smooth and efficient production of concrete. Their key responsibilities include:

1. Operating Batching Equipment

Using sophisticated equipment to accurately measure, batch, and mix various materials, including cement, aggregates, water, and admixtures, to create concrete blends that meet specified requirements.

2. Monitoring and Controlling Production

Continuously monitoring the batching process, adjusting equipment settings, and maintaining optimal operating conditions to ensure consistent concrete quality and prevent production delays.

3. Maintaining Equipment and Facility

Performing routine maintenance and inspections of batching equipment, conveyors, and other components to prevent breakdowns and ensure the smooth execution of the production process.

4. Following Safety Protocols

Adhering strictly to established safety regulations, wearing appropriate protective gear, and maintaining a clean and organized work environment to minimize the risk of accidents and injuries.

Interview Tips

Preparing thoroughly for a Batcher Operator interview can significantly increase your chances of success. Here are some valuable interview tips to help you excel:

1. Research the Company and Industry

Familiarize yourself with the company’s background, history, products, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

2. Practice Answering Common Interview Questions

Prepare responses to common interview questions related to your skills, experience, and qualifications. Practice your answers aloud to gain confidence and deliver them clearly and concisely.

3. Prepare Examples of Your Experience

Provide specific examples from your professional background that highlight your proficiency in batching operations, troubleshooting, and safety compliance. Quantifying your accomplishments with data will make them more impactful.

4. Highlight Your Problem-Solving Skills

Interviewers will be interested in your ability to solve problems and make decisions quickly. Share examples where you effectively identified and resolved technical issues or production challenges.

5. Emphasize Your Safety Consciousness

Safety is paramount in manufacturing. Showcase your commitment to safety by describing your understanding of industry regulations, your adherence to best practices, and any safety initiatives you have implemented.

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately and arrive for your interview on time to demonstrate your professionalism and respect for the position and company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Batcher Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.