Are you gearing up for a career in Batching Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Batching Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

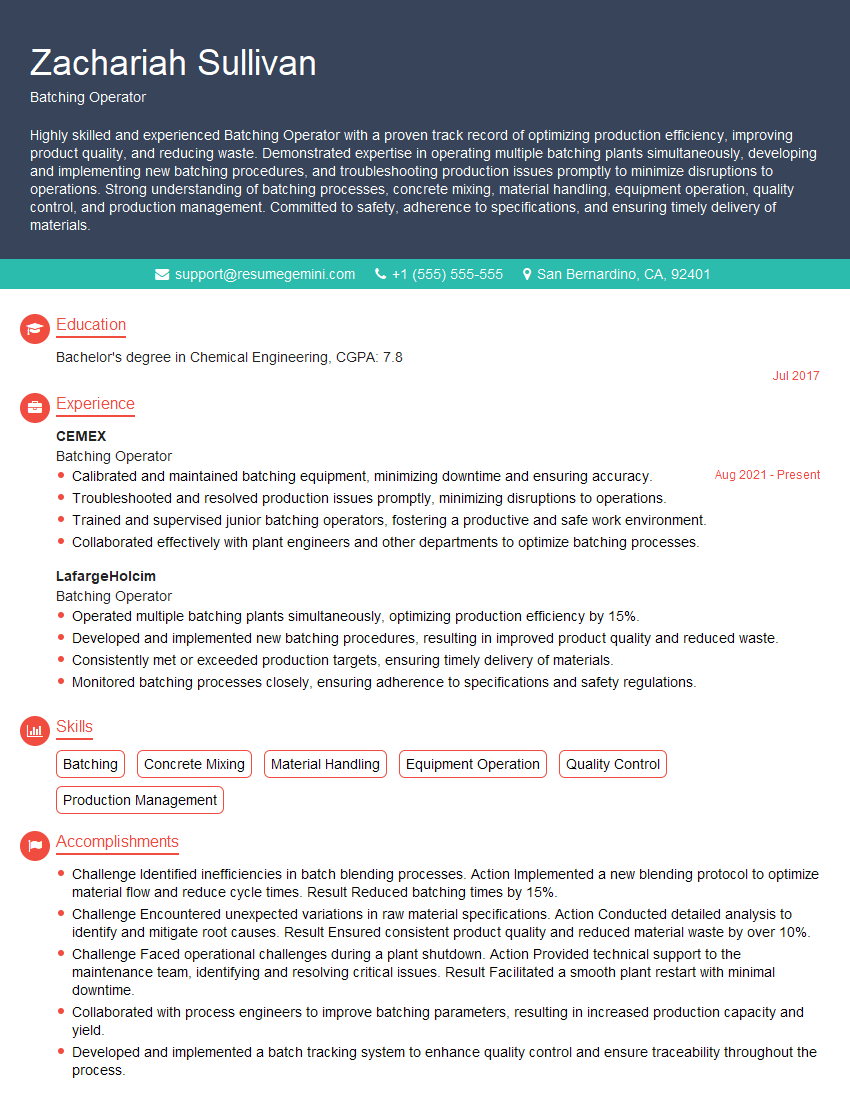

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batching Operator

1. Explain the process of batching concrete?

The process involves several key steps:

- Weighing and loading ingredients: Raw materials, such as cement, sand, aggregates, and water, are weighed and loaded into the batching plant.

- Mixing ingredients: The materials are mixed together in a mixer to create the concrete mixture.

- Discharging the concrete: The mixed concrete is discharged from the mixer into a truck or other container for transportation.

2. Describe the different types of batching plants?

Central mix plant:

- Mixing occurs at the plant, and the concrete is transported ready-mixed to the construction site.

Transit mix plant:

- Materials are loaded into a truck mixer, and mixing takes place during transportation to the construction site.

Mobile batching plant:

- A compact and portable plant that can be moved to different locations as needed.

3. What factors affect the quality of the concrete batch?

Several factors influence the quality of the concrete batch:

- Ingredient proportions: Precise measurement and proportions of cement, aggregates, and water are crucial.

- Mixing time: Adequate mixing ensures a uniform and consistent concrete mixture.

- Water content: Water-to-cement ratio significantly affects concrete strength and durability.

- Temperature: Extreme temperatures can impact the setting and curing process of concrete.

4. How do you ensure the accuracy of the batching process?

To ensure accuracy:

- Calibrating equipment: Regular calibration of weighing scales and other equipment is essential.

- Following procedures: Adhering to established batching procedures and protocols.

- Quality control: Conducting tests and inspections to verify the quality of the concrete batches.

5. What are the safety precautions when operating a batching plant?

- Wear appropriate PPE: Including safety glasses, gloves, and earplugs.

- Inspect equipment: Before operating, ensure all machinery is in good working condition.

- Follow safety procedures: Adhere to established protocols for handling hazardous materials and operating equipment.

- Be aware of surroundings: Pay attention to moving vehicles, equipment, and other personnel.

6. What maintenance tasks are typically performed on a batching plant?

Regular maintenance includes:

- Equipment cleaning: Removing concrete buildup and debris.

- Lubrication: Greasing moving parts to ensure smooth operation.

- Inspection: Checking for wear and tear, loose bolts, or other issues.

- Calibration: Ensuring the accuracy of weighing scales and other instruments.

7. How do you troubleshoot common batching plant issues?

- Concrete not mixing properly: Check for issues with mixer paddles, blade alignment, or mixing time.

- Inaccurate batch weights: Calibrate weighing scales, inspect for damage, or ensure proper loading procedures.

- Equipment breakdowns: Identify the faulty component, determine the cause, and perform necessary repairs or replacements.

8. How do you handle variations in raw material quality?

To manage variations:

- Test materials: Conduct regular tests to assess the quality of incoming raw materials.

- Adjust batch proportions: Modify the mix design to compensate for variations in material properties.

- Monitor concrete performance: Track the quality of the concrete produced to ensure it meets specifications.

9. What are the environmental considerations when operating a batching plant?

- Dust control: Implement measures to minimize dust emissions, such as dust collectors and water sprays.

- Waste management: Dispose of concrete waste and wash water responsibly to prevent environmental pollution.

- Noise reduction: Employ noise-dampening techniques to minimize noise levels.

10. Describe your experience with different types of concrete mixtures?

In my previous role, I worked with a wide range of concrete mixtures, including:

- Normal-strength concrete: Used for general construction purposes, such as foundations, walls, and slabs.

- High-strength concrete: Designed for structures requiring high load-bearing capacity, such as bridges and skyscrapers.

- Self-compacting concrete: Formulated to flow and fill complex shapes without the need for vibration.

- Lightweight concrete: Incorporates lightweight aggregates to reduce the density of the concrete.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batching Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batching Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Batching Operators are responsible for preparing and processing various batches of materials following predefined procedures. They operate and maintain batching equipment, ensuring accurate measurement and mixing of ingredients to create consistent and high-quality products.

1. Batch Preparation and Processing

- Accurately measure and weigh ingredients based on standardized recipes and batch instructions.

- Load ingredients into appropriate mixing vessels or equipment.

- Thoroughly mix and blend ingredients according to established procedures and quality standards.

- Verify batch consistency and homogeneity to meet product specifications.

- Monitor and record batch processing parameters, such as temperature, mixing speed, and duration.

2. Equipment Operation and Maintenance

- Safely operate and maintain batching equipment, including scales, mixers, conveyors, and packaging systems.

- Perform regular equipment inspections and calibrations to ensure accuracy and optimal performance.

- Detect and resolve equipment malfunctions promptly and efficiently.

- Follow established maintenance procedures and schedules to maximize equipment uptime and prevent breakdowns.

3. Quality Control and Assurance

- Adhere to quality control protocols and maintain a clean and organized work environment.

- Conduct in-process quality checks to identify any deviations from specifications.

- Record batch data, including ingredient weights, mixing parameters, and quality control results.

- Report any quality issues or concerns promptly to supervisors or quality control personnel.

4. Safety and Environmental Compliance

- Follow all applicable safety regulations and procedures while operating equipment and handling materials.

- Wear appropriate personal protective equipment (PPE) to minimize risks.

- Adhere to environmental regulations and dispose of materials properly.

- Report any safety hazards or non-compliance issues to supervisors or management.

Interview Tips

To prepare for your Batching Operator interview, consider the following tips and hacks:

1. Research the Company and Industry

- Learn about the company’s culture, mission, and products.

- Research the industry’s best practices and technological advancements.

- Understand the company’s quality control standards and safety protocols.

2. Highlight Your Technical Skills

- Emphasize your proficiency in operating batching equipment and performing quality control procedures.

- Quantify your experience in measuring, weighing, and blending ingredients.

- Demonstrate your understanding of ingredient properties and their impact on final product quality.

3. Showcase Your Problem-Solving Abilities

- Share examples of how you solved equipment malfunctions or resolved quality issues.

- Discuss your ability to troubleshoot problems and identify root causes.

- Emphasize your attention to detail and willingness to learn and adapt.

4. Prepare for Behavioral Questions

- Be ready to discuss your ability to work independently and as part of a team.

- Highlight your communication and interpersonal skills.

- Provide examples of how you have demonstrated responsibility and initiative.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batching Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!