Are you gearing up for an interview for a Battery Charger, Conveyor Line position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Battery Charger, Conveyor Line and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

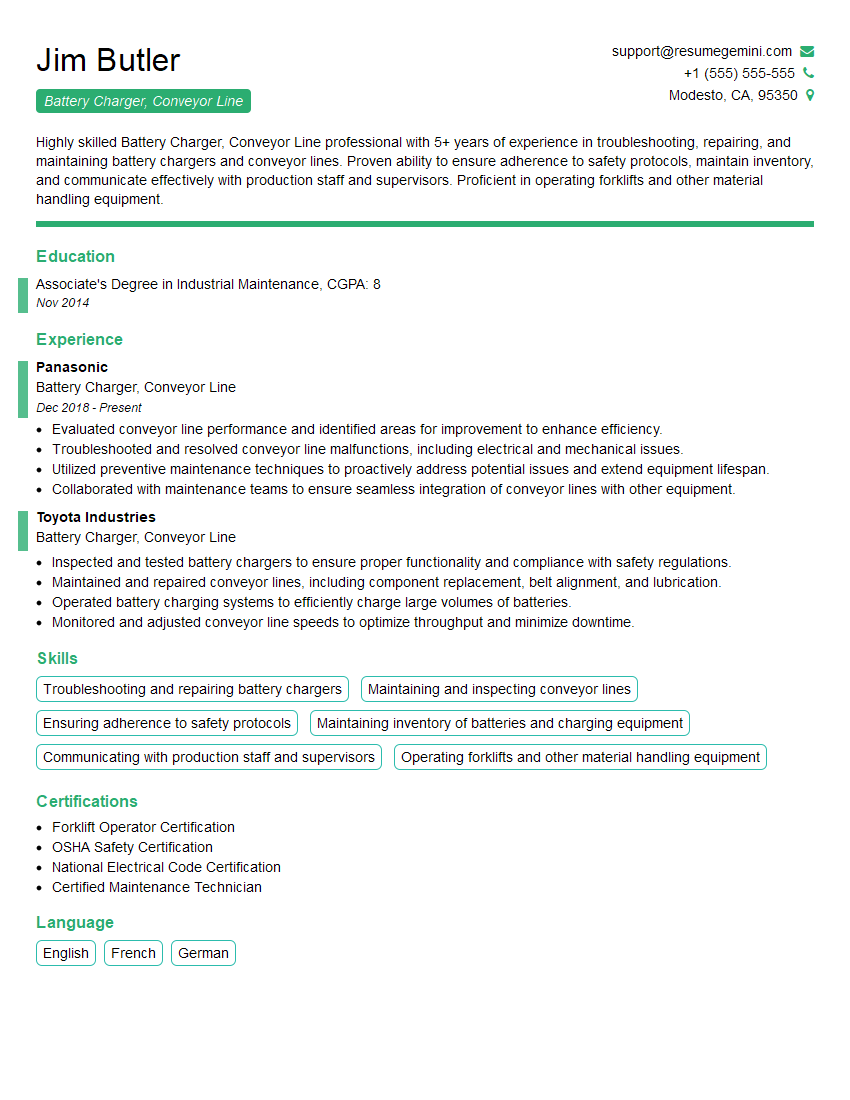

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Battery Charger, Conveyor Line

1. What are the different types of battery chargers available and how do they work?

There are two main types of battery chargers: linear and switch-mode.

- Linear chargers are simpler and less expensive than switch-mode chargers, but they are also less efficient. Linear chargers work by applying a constant voltage to the battery until it is fully charged.

- Switch-mode chargers are more efficient than linear chargers, but they are also more complex and expensive. Switch-mode chargers work by switching the voltage applied to the battery between a high voltage and a low voltage. This allows the charger to regulate the current flowing into the battery, which results in a more efficient charge.

2. What are the safety precautions that should be taken when working with battery chargers?

- Always wear safety glasses and gloves when working with battery chargers.

- Never connect a battery charger to a battery that is not properly ventilated.

- Never charge a battery that is damaged or leaking.

- Never leave a battery charger unattended while it is charging a battery.

- Always disconnect the battery charger from the battery before performing any maintenance or repairs.

3. How do you troubleshoot a battery charger that is not working?

- First, check to make sure that the battery charger is properly connected to the battery.

- Next, check the battery charger’s fuse to see if it has blown.

- If the fuse is blown, replace it with a new fuse of the same amperage.

- If the fuse is not blown, then the battery charger may be faulty and will need to be repaired or replaced.

4. What is a conveyor line and how does it work?

A conveyor line is a system that moves materials from one place to another. Conveyor lines are used in a variety of industries, including manufacturing, food processing, and packaging.

Conveyor lines consist of a series of rollers or belts that are driven by a motor. The materials to be moved are placed on the rollers or belts, which then carry them to their destination.

5. What are the different types of conveyor lines?

There are a variety of different types of conveyor lines, including:

- Roller conveyors: Roller conveyors are the most common type of conveyor line. They consist of a series of rollers that are driven by a motor. The materials to be moved are placed on the rollers, which then carry them to their destination.

- Belt conveyors: Belt conveyors are similar to roller conveyors, but they use a belt instead of rollers to move the materials.

- Chain conveyors: Chain conveyors use a chain to move the materials. Chain conveyors are often used in applications where the materials need to be moved uphill or downhill.

- Screw conveyors: Screw conveyors use a screw to move the materials. Screw conveyors are often used in applications where the materials need to be moved in a confined space.

6. How do you maintain a conveyor line?

To maintain a conveyor line, you should:

- Inspect the conveyor line regularly for any damage.

- Clean the conveyor line regularly to remove any dirt or debris.

- Lubricate the conveyor line regularly to keep it running smoothly.

- Tighten any loose bolts or screws.

- Replace any worn or damaged parts.

7. What are the safety precautions that should be taken when working with conveyor lines?

- Always wear safety glasses and gloves when working with conveyor lines.

- Never wear loose clothing or jewelry when working with conveyor lines.

- Never step on or over a conveyor line while it is in operation.

- Never reach into a conveyor line while it is in operation.

- Always shut off the conveyor line before performing any maintenance or repairs.

8. How do you troubleshoot a conveyor line that is not working?

- First, check to make sure that the conveyor line is properly connected to the power source.

- Next, check the conveyor line’s motor to see if it is running.

- If the motor is not running, check the conveyor line’s fuse to see if it has blown.

- If the fuse is blown, replace it with a new fuse of the same amperage.

- If the fuse is not blown, then the conveyor line may be faulty and will need to be repaired or replaced.

9. What is the difference between a battery charger and a power supply?

A battery charger is used to charge a battery, while a power supply is used to provide power to a device.

Battery chargers typically have a higher voltage output than power supplies, and they are able to provide a higher current. This is because batteries need to be charged with a higher voltage and current in order to reach their full capacity.

Power supplies, on the other hand, typically have a lower voltage output than battery chargers, and they are able to provide a lower current. This is because most devices do not require a high voltage or current to operate.

10. What are the different types of power supplies?

There are a variety of different types of power supplies, including:

- AC power supplies: AC power supplies provide alternating current (AC) power. AC power is the type of power that is supplied by most household outlets.

- DC power supplies: DC power supplies provide direct current (DC) power. DC power is the type of power that is used by most electronic devices.

- Linear power supplies: Linear power supplies use a transformer to convert AC power to DC power. Linear power supplies are typically larger and heavier than switching power supplies.

- Switching power supplies: Switching power supplies use a switching transistor to convert AC power to DC power. Switching power supplies are typically smaller and lighter than linear power supplies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Battery Charger, Conveyor Line.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Battery Charger, Conveyor Line‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Battery Chargers, Conveyor Lines play a crucial role in ensuring the smooth operation of industrial processes by consistently providing charged batteries and maintaining the efficient flow of materials. Their responsibilities include:

1. Battery Charging and Maintenance

Ensuring that all batteries are correctly charged and maintained to meet operational requirements.

- Monitoring battery levels and performing timely recharging

- Inspecting batteries for damage and replacing them when necessary

- Maintaining proper charging records and ensuring compliance with safety regulations

2. Conveyor Line Operation

Operating and maintaining conveyor lines to facilitate the movement of materials and products.

- Starting, stopping, and adjusting conveyor lines as per production schedules

- Inspecting and cleaning conveyor belts, rollers, and other components

- Identifying and resolving any conveyor line malfunctions or blockages

3. Material Handling

Handling and moving various materials along the conveyor line to meet production demands.

- Loading and unloading materials onto the conveyor line

- Monitoring the flow of materials and adjusting conveyor speed as required

- Ensuring materials are transported safely and efficiently

4. Equipment Maintenance

Performing basic maintenance tasks on both battery chargers and conveyor lines to ensure optimal performance.

- Cleaning and lubricating equipment components

- Inspecting for worn or damaged parts and making necessary replacements

- Reporting any major repairs or maintenance needs to supervisors

Interview Tips

Preparing for a job interview requires careful planning and practice. Here are some tips to help candidates ace their interview for the Battery Charger, Conveyor Line position:

1. Research the Company and Role

Thoroughly research the company’s background, values, and the specific requirements of the Battery Charger, Conveyor Line role. This knowledge will demonstrate your interest and understanding of the position.

- Visit the company website and social media pages

- Read industry news and articles related to battery charging and conveyor systems

- Identify key skills and experience mentioned in the job description

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. Consider using the STAR method to structure your responses (Situation, Task, Action, Result).

- Describe a time you successfully troubleshooted a conveyor line malfunction

- Explain how you ensure that batteries are charged and maintained safely

- Provide an example of how you handled a high-volume workload on the conveyor line

3. Highlight Your Skills and Experience

During the interview, confidently present your skills and experience that align with the job requirements. Quantify your accomplishments and provide specific examples to showcase your abilities.

- Emphasize your experience in battery charging and maintenance

- Discuss your proficiency in operating and maintaining conveyor lines

- Highlight your material handling skills and ability to work efficiently in a fast-paced environment

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that are specific to the role or the company to gather more information.

- What are the current challenges facing the battery charging and conveyor line operations?

- How does the company prioritize safety in these operations?

- What opportunities are there for professional development and growth within the organization?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Battery Charger, Conveyor Line interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!