Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Batting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Batting Machine Operator so you can tailor your answers to impress potential employers.

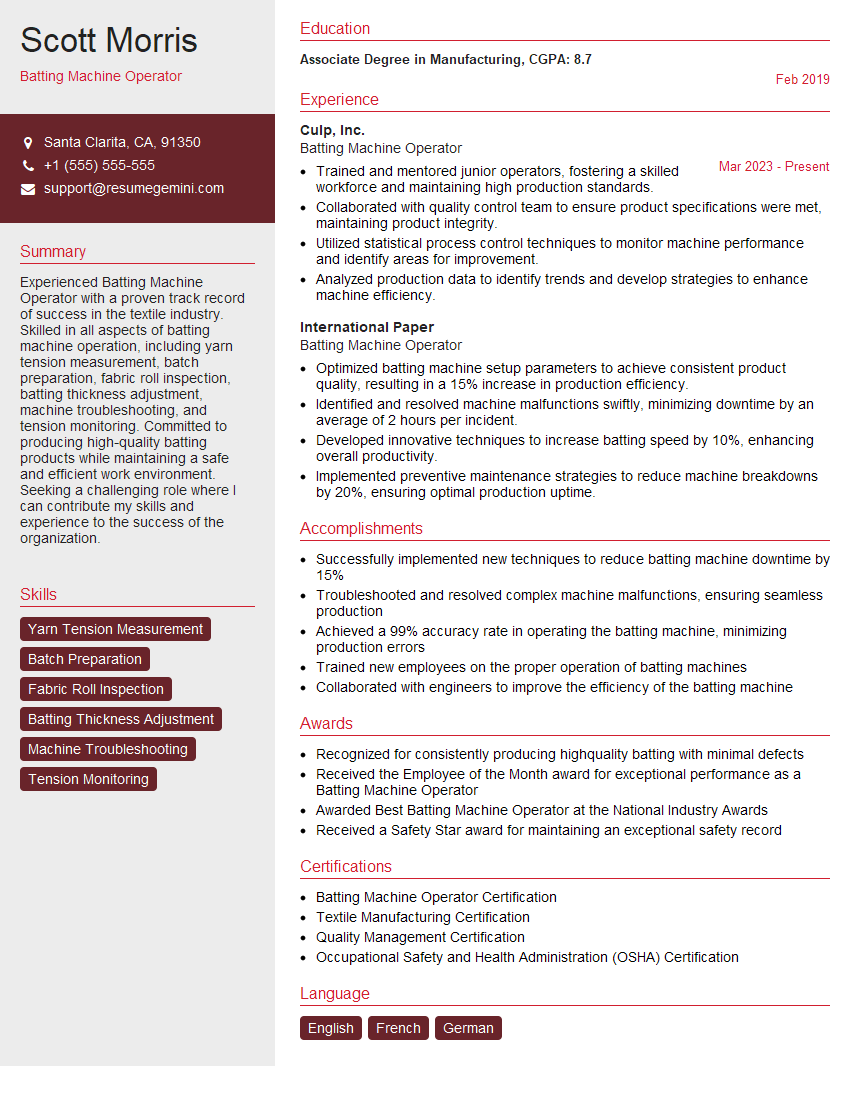

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batting Machine Operator

1. How do you ensure the accuracy of the batting machine during operation?

- Regularly calibrate the machine to ensure it meets accuracy standards.

- Inspect the machine for any signs of wear or damage that could affect its accuracy.

- Use high-quality batting materials that are consistent in thickness and density.

- Monitor the batting process closely and make adjustments as needed to maintain consistency.

2. What are the different types of batting machines and their uses?

Manual Batting Machine:

- Operated by manually turning a crank or handle.

- Used for small-scale or hobby batting purposes.

Semi-Automatic Batting Machine:

- Uses a motor to feed the batting materials and control the batting cycle.

- Requires manual loading and unloading of materials.

Automatic Batting Machine:

- Fully automated process with automatic loading, batting, and unloading.

- Used for high-volume and precision batting.

3. How do you handle and prevent common malfunctions in a batting machine?

- Regularly clean and lubricate the machine to prevent jamming.

- Inspect the batting materials for any foreign objects or defects that could cause problems.

- Check the machine’s settings and make adjustments as necessary to ensure optimal performance.

- Troubleshoot and resolve minor malfunctions such as loose connections or sensor issues.

4. What are the safety precautions you follow when operating a batting machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands and loose clothing clear of the machine’s moving parts.

- Never operate the machine when it is not properly assembled or guarded.

- Follow the manufacturer’s instructions and safety guidelines carefully.

5. How do you maintain the quality of the batting materials used in the machine?

- Source batting materials from reputable suppliers to ensure quality standards.

- Store the materials properly to prevent damage or deterioration.

- Inspect the materials regularly for any defects or contamination.

- Use the appropriate batting materials for the specific machine and application.

6. What is the role of thread tension in the batting process and how do you adjust it?

- Thread tension controls the tightness of the stitches in the batting material.

- Improper tension can lead to loose or broken stitches, affecting the quality of the batting.

- Adjust the thread tension by loosening or tightening the tension dial on the machine.

- Use a test piece of material to determine the optimal tension setting for the specific material and application.

7. How do you troubleshoot and resolve issues related to skipped stitches in the batting?

- Check the thread tension and adjust it if necessary.

- Inspect the needle for damage or wear and replace it if needed.

- Clean the machine’s bobbin and tension discs to remove any lint or debris.

- Ensure that the batting materials are properly loaded and not tangled.

8. What is the difference between single-needle and multiple-needle batting machines?

- Single-needle machines use a single needle to create a single line of stitches.

- Multiple-needle machines use multiple needles to create multiple lines of stitches simultaneously.

- Multiple-needle machines can increase productivity and create denser batting.

9. How do you maintain the cleanliness and hygiene of the batting machine?

- Regularly clean the machine’s exterior and interior surfaces with a damp cloth.

- Use a vacuum cleaner to remove any lint or dust accumulations.

- Lubricate the machine’s moving parts according to the manufacturer’s instructions.

- Sanitize the machine’s surfaces with an appropriate disinfectant to prevent the spread of bacteria.

10. What are the industry-standard quality control measures for batting operations?

- Regular testing of batting materials to ensure they meet specifications.

- Inspection of finished products for defects, such as skipped stitches or uneven batting density.

- Maintaining records of batting parameters and quality checks.

- Adhering to industry standards and best practices for batting operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Batting Machine Operator is responsible for operating and maintaining batting machines, which are used to apply batting to textiles. Their key job responsibilities include:

1. Operating Batting Machines

Batting Machine Operators are responsible for setting up, operating, and maintaining batting machines. This includes loading the machine with batting material, adjusting the machine settings, and monitoring the machine’s operation.

- Loading the batting machine with the appropriate batting material

- Adjusting the machine settings, such as the batting speed and tension

- Monitoring the machine’s operation and making adjustments as needed

2. Maintaining Batting Machines

Batting Machine Operators are also responsible for maintaining batting machines. This includes cleaning the machine, lubricating moving parts, and making minor repairs.

- Cleaning the batting machine regularly

- Lubricating moving parts of the batting machine

- Making minor repairs to the batting machine, such as replacing worn parts

3. Inspecting Batting

Batting Machine Operators are responsible for inspecting the batting produced by the machine. This includes checking the batting for defects, such as holes, tears, or uneven thickness.

- Inspecting the batting for defects

- Rejecting batting that does not meet quality standards

- Reporting any defects to the supervisor

4. Other Duties

In addition to the above responsibilities, Batting Machine Operators may also be responsible for:

- Assisting with the loading and unloading of batting materials

- Maintaining a clean and organized work area

- Following all safety procedures

Interview Tips

Preparing for an interview for a Batting Machine Operator position can be daunting, but following these tips can help you increase your chances of success:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, values, and goals, and will allow you to tailor your answers to the interviewer’s questions.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience operating batting machines and maintaining textile equipment. Be prepared to discuss your skills and experience in detail, and be sure to highlight any accomplishments or awards you have received.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, and maintain a positive attitude throughout the interview. Your enthusiasm for the position will be evident to the interviewer, and it will increase your chances of being hired.

5. Follow Up After the Interview

After the interview, take the time to send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration, and it can help you stay top-of-mind for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!