Feeling lost in a sea of interview questions? Landed that dream interview for Bead Forming Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bead Forming Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

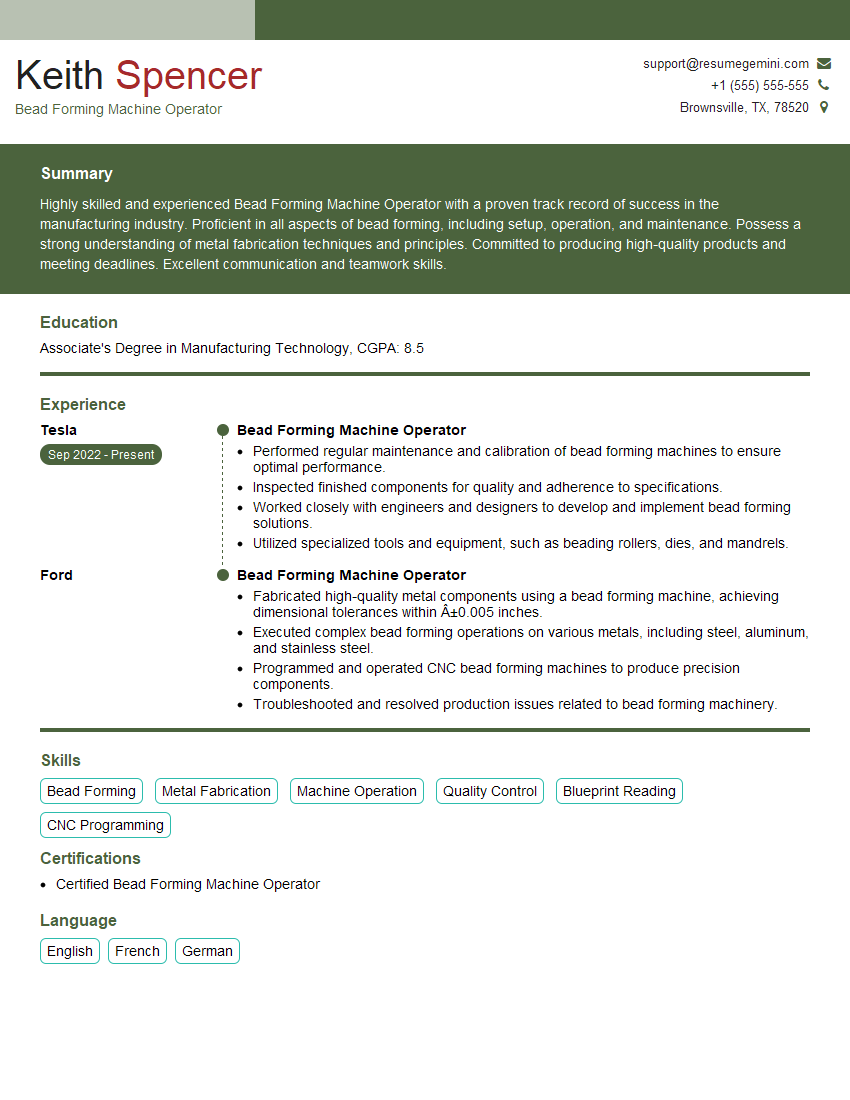

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bead Forming Machine Operator

1. Can you describe the different types of bead forming machines and their applications?

There are many different types of bead forming machines, each with its own unique set of capabilities and applications. Some of the most common types of bead forming machines include:

- Hand-operated bead forming machines: These machines are typically used for small-scale operations and are manually operated. They are relatively inexpensive and easy to use, making them a good option for hobbyists and small businesses.

- Foot-operated bead forming machines: These machines are similar to hand-operated bead forming machines, but they are foot-operated, which allows for greater control and precision. They are typically used for medium-scale operations and are a good option for small businesses and manufacturers.

- Hydraulic bead forming machines: These machines are powered by hydraulics and are capable of producing high-quality beads. They are typically used for large-scale operations and are a good option for manufacturers and industrial applications.

- CNC bead forming machines: These machines are computer-controlled and are capable of producing complex beads with high precision. They are typically used for large-scale operations and are a good option for manufacturers and industrial applications.

2. What are the key factors to consider when selecting a bead forming machine?

Factors to consider when selecting a bead forming machine include:

- The type of bead that you want to produce

- The material that you will be using

- The volume of beads that you will be producing

- The budget that you have available

In addition to these factors, you should also consider the following:

- The reputation of the manufacturer

- The warranty that is offered

- The availability of technical support

3. What are the different techniques used for bead forming?

There are many different techniques used for bead forming, each with its own unique advantages and disadvantages. Some of the most common bead forming techniques include:

- Hammering: This is the most basic bead forming technique and involves using a hammer to pound metal into a bead shape.

- Rolling: This technique involves using a rolling mill to roll metal into a bead shape.

- Spinning: This technique involves using a lathe to spin metal into a bead shape.

- Drawing: This technique involves using a drawbench to pull metal through a die to form a bead shape.

- Pressing: This technique involves using a press to form metal into a bead shape.

4. What are the common problems that you may encounter when operating a bead forming machine?

There are a number of common problems that you may encounter when operating a bead forming machine, including:

- The bead is not the correct size or shape.

- The bead is not smooth or has burrs.

- The bead is not strong enough.

- The bead is not consistent.

These problems can be caused by a number of factors, including:

- Incorrect machine setup

- Incorrect tooling

- Improper material handling

- Lack of operator training

5. How do you maintain a bead forming machine?

To maintain a bead forming machine, you should perform the following tasks on a regular basis:

- Clean the machine thoroughly.

- Inspect the machine for any damage.

- Lubricate the machine according to the manufacturer’s instructions.

- Calibrate the machine according to the manufacturer’s instructions.

- Train operators on how to use the machine safely and correctly.

6. What are the safety precautions that you should take when operating a bead forming machine?

When operating a bead forming machine, you should always take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine if you are tired or under the influence of drugs or alcohol.

- Be aware of the location of the emergency stop button.

- Never place your hands or fingers near the moving parts of the machine.

7. What is your experience with troubleshooting bead forming machines?

I have experience troubleshooting a variety of bead forming machines, including hand-operated, foot-operated, hydraulic, and CNC machines. I am familiar with the common problems that can occur with these machines and I know how to quickly and efficiently resolve them.

8. What is your experience with setting up and calibrating bead forming machines?

I have experience setting up and calibrating a variety of bead forming machines, including hand-operated, foot-operated, hydraulic, and CNC machines. I am familiar with the different types of adjustments that need to be made and I know how to make these adjustments accurately and efficiently.

9. What is your experience with training operators on how to use bead forming machines?

I have experience training operators on how to use a variety of bead forming machines, including hand-operated, foot-operated, hydraulic, and CNC machines. I am familiar with the different safety precautions that need to be taken when operating these machines and I know how to teach operators how to use them safely and correctly.

10. What are your career goals?

My career goal is to become a master bead forming machine operator. I am passionate about bead forming and I am always looking for ways to improve my skills. I am confident that with my experience and dedication, I can achieve my goal.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bead Forming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bead Forming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bead Forming Machine Operators are responsible for operating and maintaining bead forming machines to produce various metal products. They follow blueprints and work orders to shape and form beads in metal, providing key support in the manufacturing process. Here are the detailed job responsibilities:

1. Machine Operation and Setup

Setting up and operating bead forming machines according to specifications

- Calibrating and adjusting the machine to meet desired parameters

- Loading and unloading metal sheets or coils into the machine

2. Bead Forming

Creating beads in metal sheets or coils using the machine’s forming rollers

- Monitoring the beading process, ensuring consistent quality and accuracy

- Inspecting and measuring formed beads to meet specified dimensions

3. Maintenance and Troubleshooting

Performing routine maintenance tasks to ensure optimal machine performance

- Identifying and troubleshooting any machine malfunctions or issues

- Maintaining a clean and organized work area

4. Material Handling

Handling metal sheets, coils, and finished products with care

- Loading and unloading materials onto conveyors or lifts

- Inspecting incoming materials for quality and ensuring proper storage

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your qualifications and making a positive impression. Here are some key tips and strategies to help you ace the interview for a Bead Forming Machine Operator position:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company’s industry, products, and company culture. Review the specific job description to understand the company’s expectations and requirements for the role.

- Visit the company website, read industry news, and connect with current or former employees on LinkedIn.

- Identify the key responsibilities and qualifications outlined in the job description, and highlight how your skills and experience align with them.

2. Prepare for Technical Questions

Bead Forming Machine Operators require a strong understanding of machine operation, metalworking techniques, and quality control. Be prepared to answer questions related to:

- Bead forming machine setup and calibration

- Different bead forming techniques and their applications

- Quality control procedures and inspection methods

- Troubleshooting common machine malfunctions

3. Highlight Your Experience and Skills

Emphasize your relevant experience operating bead forming machines or similar equipment. Quantify your accomplishments by providing specific examples and metrics.

- Describe your contributions to improving productivity or reducing waste.

- Showcase your ability to identify and resolve machine issues quickly.

- Highlight your attention to detail and commitment to producing high-quality products.

4. Demonstrate Safety Awareness

Safety is paramount in manufacturing environments. Emphasize your adherence to safety protocols and your understanding of safe operating procedures.

- Describe your experience with wearing personal protective equipment (PPE) and following safety guidelines.

- Explain your familiarity with lockout/tagout procedures and other safety measures.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare a few questions related to the company, the position, or the industry.

- Inquire about the company’s growth plans or upcoming projects.

- Ask about opportunities for professional development or advancement.

- Seek clarity on any aspects of the job description or the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bead Forming Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bead Forming Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.