Feeling lost in a sea of interview questions? Landed that dream interview for Bead Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bead Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

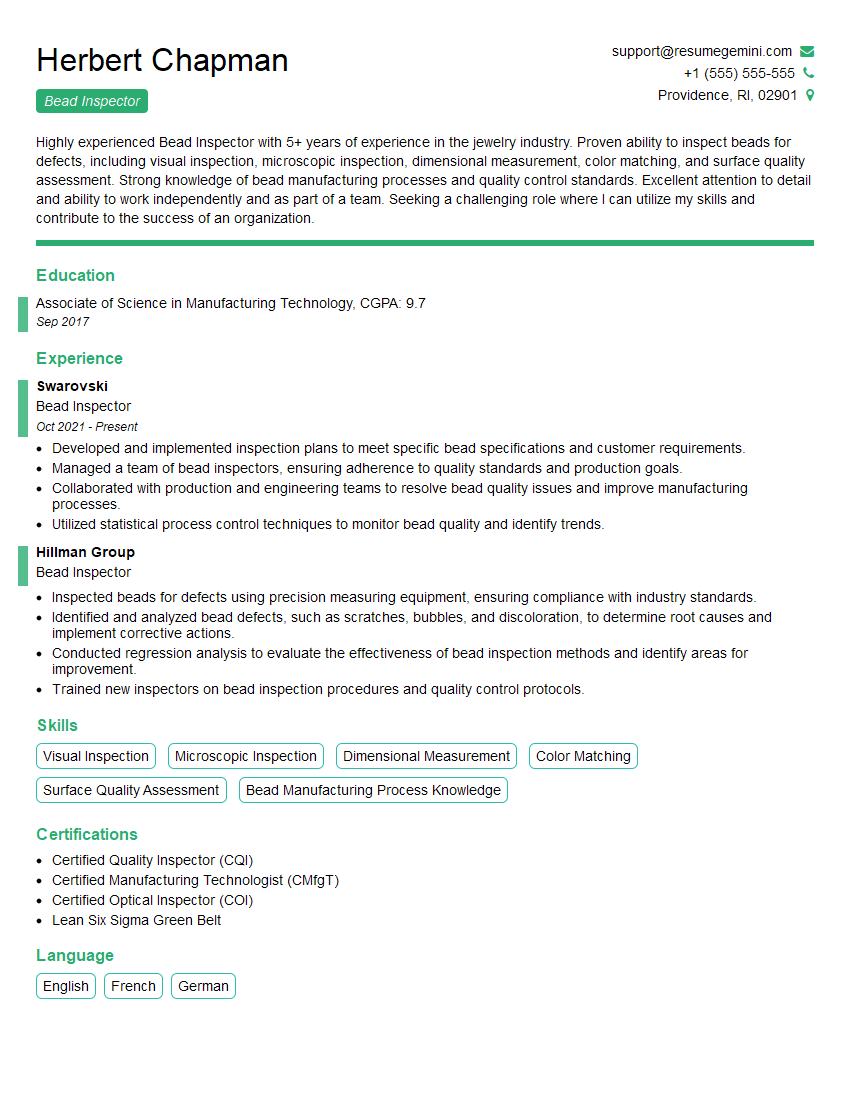

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bead Inspector

1. Explain the process of inspecting beads for quality?

- Beads are visually inspected for any defects, such as cracks, chips, or scratches.

- The beads are also measured to ensure that they meet the specified size and shape requirements.

- The beads are then sorted and packaged according to their quality.

2. What are the different types of defects that you can identify in beads?

Types of Defects

- Cracks: These are breaks in the bead’s surface that can be caused by impact or stress.

- Chips: These are small pieces of the bead that have broken off.

Other Defects

- Scratches: These are lines or grooves on the bead’s surface that can be caused by friction.

- Pits: These are small holes in the bead’s surface that can be caused by air bubbles or impurities.

3. What are the critical dimensions of a bead that you inspect?

- Diameter

- Length

- Hole size

- Shape

4. What is the tolerance for each of the critical dimensions?

- Diameter: ±0.05 mm

- Length: ±0.10 mm

- Hole size: ±0.02 mm

- Shape: Must be within specified limits

5. What is the difference between a major and a minor defect?

- Major defects: These are defects that make the bead unusable. They can include cracks, chips, or holes.

- Minor defects: These are defects that do not make the bead unusable. They can include scratches, pits, or discolorations.

6. What is your process for identifying and sorting beads?

- The beads are first visually inspected for any defects.

- The beads are then measured to ensure that they meet the specified size and shape requirements.

- The beads are then sorted into different grades based on their quality.

7. What is your experience with using inspection equipment?

- I have experience using a variety of inspection equipment, including optical comparators, micrometers, and calipers.

- I am also familiar with the use of statistical process control (SPC) techniques.

8. What are your quality standards?

- I follow the quality standards that are established by my employer.

- I also adhere to the ISO 9001 quality management system.

9. How do you stay up-to-date on the latest inspection techniques?

- I attend industry conferences and workshops.

- I read trade publications and journals.

- I am also involved in online discussion forums.

10. What are your strengths and weaknesses?

Strengths

- Strong attention to detail

- Excellent visual acuity

- Experience with a variety of inspection equipment

- Knowledge of quality standards and SPC techniques

Weaknesses

- I can be a bit of a perfectionist at times.

- I am not always the best at working under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bead Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bead Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bead Inspectors are responsible for ensuring the quality of glass beads or other types of beads used in various industries. Their meticulous inspections guarantee that beads meet the required specifications and standards.

1. Inspecting Beads

Bead Inspectors meticulously examine beads to identify defects or non-conformities. They may use magnifying glasses, microscopes, or other specialized equipment to scrutinize the beads’ shape, size, color, and surface finish.

- Verify dimensions and tolerances using measuring tools

- Detect flaws, imperfections, or contamination on bead surfaces

2. Maintaining Quality Standards

Bead Inspectors uphold established quality standards. They compare beads against predetermined specifications and identify any deviations. By adhering to these standards, they ensure the integrity of bead products.

- Follow industry standards and company protocols for bead inspection

- Evaluate beads based on criteria such as color, clarity, and finish

3. Documentation and Reporting

Bead Inspectors meticulously document their findings. They maintain accurate records of inspections, identifying any non-conforming beads. These reports facilitate quality control and provide valuable insights for improving production processes.

- Record inspection results, including bead defects and measurements

- Prepare reports summarizing inspection findings and make recommendations

4. Equipment Maintenance

Bead Inspectors ensure the proper functioning of inspection equipment. They perform regular maintenance, calibration, and cleaning to maintain the accuracy and precision of the equipment.

- Calibrate and maintain inspection tools, such as microscopes and measuring devices

- Troubleshoot equipment issues and perform minor repairs

Interview Tips

Preparing thoroughly for a Bead Inspector interview can significantly increase your chances of success. Here are some valuable tips and strategies to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and the industry by researching their products, services, and market reputation. Understanding the company’s culture and values will show the interviewer that you are genuinely interested in the role and the organization.

- Visit the company’s website and social media pages

- Read industry news and articles to stay updated on trends

2. Practice Answering Common Questions

Prepare answers to common interview questions related to your skills, experience, and qualifications. Practice delivering your responses clearly and concisely, highlighting your strengths and how they align with the job requirements.

- Describe your experience in bead inspection, including the types of beads you have inspected and the techniques you used

- Explain your understanding of quality control standards and how you ensure adherence to them

3. Highlight Your Attention to Detail

Emphasize your meticulous nature and ability to identify even the smallest defects. Bead inspection requires a sharp eye for detail and the ability to focus for extended periods. Provide examples from your previous experience that demonstrate your keen observation skills.

- Discuss a time when you detected a subtle flaw in a bead that others may have missed

- Explain how your attention to detail has contributed to improving product quality

4. Show Your Commitment to Quality

Convey your passion for maintaining high standards and your dedication to delivering quality products. Explain how you approach quality control tasks with a proactive mindset and a continuous improvement attitude.

- Describe your involvement in quality improvement initiatives or your suggestions for enhancing inspection processes

- Share examples of how you have gone above and beyond to ensure the quality of beads

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare questions that show you are curious about the company’s operations, the challenges faced in bead inspection, or the potential for growth within the organization.

- Inquire about the company’s quality control policies and procedures

- Ask about the opportunities for professional development and advancement within the company

Next Step:

Now that you’re armed with the knowledge of Bead Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bead Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini