Are you gearing up for a career in Bead Wire Taper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bead Wire Taper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

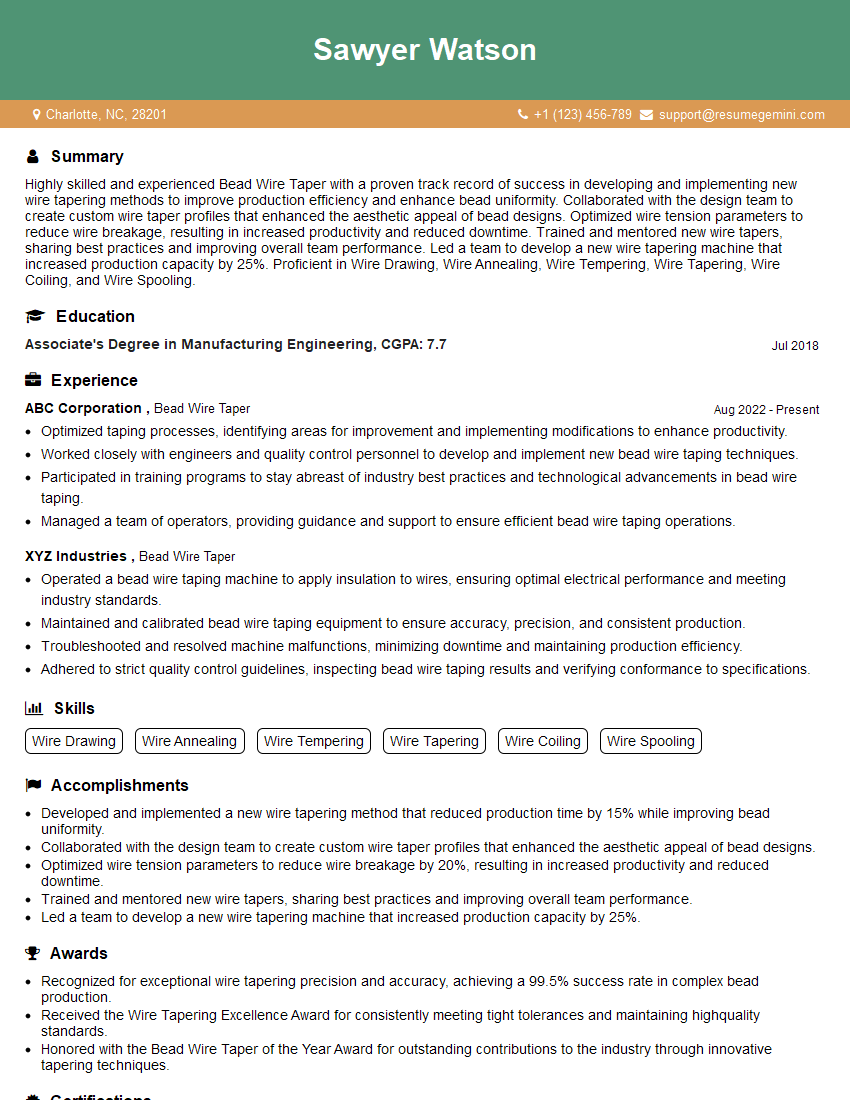

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bead Wire Taper

1. What are the different types of bead wire tapers available in the market?

There are various types of bead wire tapers, designed for specific purposes. Here are the common types available:

- Cylinder Tapers: Cylindrical tools with parallel sides, used for basic tapering operations.

- Conical Tapers: Cone-shaped tools, providing a pointed tip for precise tapering.

- Tapered Dies: Hollow tapers with tapered inner diameters, used for sizing or reducing wire diameters.

- Rolling Tapers: Grooved tapers that roll wire into various shapes, such as spirals or ovals.

- Swaging Tapers: Reducing hammers used to shape and compact wire, creating a wider range of sizes and shapes.

2. How do you choose the right bead wire taper for a specific application?

Factors to Consider:

- Wire Material: Different materials require specific tapers to avoid damage or breakage.

- Wire Size: Tapers must be appropriately sized to accommodate the diameter of the wire.

- Taper Angle: The angle of the taper determines the rate and precision of the tapering process.

- Desired Taper Shape: Consider the specific shape required, such as a pointed or rounded taper.

- Equipment Compatibility: Ensure the taper is compatible with your tapering equipment or tools.

3. What are the safety precautions to follow when using bead wire tapers?

Safety is paramount when working with bead wire tapers. Here are essential precautions to observe:

- Wear Protective Gear: Use safety glasses, gloves, and a mask to protect eyes, hands, and lungs from dust and debris.

- Secure Wire Properly: Clamp the wire securely to prevent it from slipping or tangling.

- Handle Tapers with Care: Wear gloves when handling tapers to avoid cuts or abrasions.

- Inspect Equipment Regularly: Ensure that the tapering equipment and tapers are in good condition before use.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions to operate the equipment safely and effectively.

4. How do you maintain bead wire tapers for optimal performance?

Regular maintenance is crucial to ensure consistent and long-lasting performance of bead wire tapers:

- Clean After Use: Remove debris, dust, and wire particles after each use with a brush or compressed air.

- Lubricate Regularly: Apply lubricant to the taper surface to minimize friction and extend its lifespan.

- Inspect Regularly: Check the taper for wear, damage, or corrosion to identify any issues early on.

- Store Properly: Store tapers in a dry and dust-free environment to prevent rust or corrosion.

- Follow Manufacturer’s Recommendations: Refer to the manufacturer’s guidelines for specific maintenance instructions.

5. Can you explain the process of tapering bead wire using a tapered die?

Steps Involved:

- Prepare the Wire: Ensure the wire is straight and free of burrs or irregularities.

- Lubricate the Die: Apply lubricant to the tapered die to reduce friction and prevent damage.

- Insert the Wire: Insert the wire into the die carefully, aligning it with the tapered bore.

- Apply Force: Exert controlled force (using a hammer or press) to push the wire through the die.

- Taper the Wire: As the wire passes through the die, it gradually tapers based on the die’s angle.

- Inspect the Taper: Check the tapered wire to ensure it meets the desired angle and dimensions.

6. When is it necessary to use a rolling taper or swaging taper for bead wire?

Rolling tapers and swaging tapers are used for specific purposes:

- Rolling Tapers: Used to roll wire into non-circular shapes, such as spirals, ovals, or squares.

- Swaging Tapers: Used to shape and compact wire, creating a wider range of sizes and shapes, including reducing the diameter or creating intricate patterns.

7. How do you troubleshoot a bead wire taper that is producing inconsistent or unsatisfactory results?

Troubleshooting Steps:

- Check Wire Alignment: Ensure the wire is properly aligned with the taper.

- Inspect Taper Condition: Check for wear, damage, or debris that may affect performance.

- Adjust Taper Angle: Verify if the taper angle is incorrect for the desired result.

- Apply Proper Lubricant: Use the appropriate lubricant to minimize friction and improve taper performance.

- Inspect Wire Material: Ensure the wire material is compatible with the taper and is not too hard or brittle.

8. What are some common challenges faced when tapering bead wire and how do you overcome them?

Challenges and Solutions:

- Wire Kinking: Use anti-kink devices or support the wire to prevent tangling.

- Wire Breaks: Ensure wire is properly annealed and use the correct taper size and angle.

- Taper Wear: Regularly inspect and replace tapers to avoid inconsistent results.

- Lubrication Issues: Use the appropriate lubricant to minimize friction and prevent galling.

- Safety Concerns: Always wear protective gear and follow safety protocols.

9. How do you handle different types of bead wire materials, such as copper, silver, or gold, when tapering?

Different materials have unique properties that require specific handling techniques:

- Copper: Anneal before tapering to soften it and prevent breaks.

- Silver: Use a light touch and avoid excessive force to prevent damage or deformation.

- Gold: Requires careful handling due to its high value and softness; consider using specialized tapers.

10. Explain the importance of annealing bead wire before tapering and how it affects the tapering process.

Annealing softens the wire, making it more pliable and less likely to break during tapering:

- Enhanced Ductility: Annealing reduces the wire’s tensile strength, allowing it to be shaped and tapered more easily.

- Reduced Risk of Cracks: Soft, annealed wire is less prone to cracking under stress during the tapering process.

- Improved Taper Quality: Annealed wire flows more smoothly through the taper, resulting in a cleaner and more consistent taper.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bead Wire Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bead Wire Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bead Wire Tapers are responsible for a wide range of duties crucial to the production of high-quality jewelry. Their primary tasks include:

1. Preparing and Tapering Bead Wire

The Bead Wire Taper prepares bead wire by cutting it to the desired length, straightening it, and tapering one or both ends to create a pointed or flat tip. This meticulous process ensures that the wire can be easily threaded through beads and other components during jewelry making.

- Accurately measuring and cutting wire to specified lengths.

- Using specialized tools to straighten wire, removing any kinks or bends.

- Tapering wire ends to create precise points or flat tips using precision tools.

2. Assembling and Finishing Jewelry

When required, Bead Wire Tapers contribute to the assembly and finishing of jewelry pieces. They connect beads and other components using tapered wire, ensuring secure and aesthetically pleasing results. Additionally, they may perform finishing tasks such as polishing or applying protective coatings.

- Threading beads onto tapered wire to create desired patterns.

- Joining wire ends securely using various techniques (e.g., soldering, crimping).

- Polishing or applying protective coatings to enhance the appearance and durability of jewelry.

3. Maintaining Equipment and Work Area

Bead Wire Tapers are responsible for maintaining their equipment and work area to ensure efficiency and safety. They clean and calibrate tools, organize supplies, and dispose of waste materials as necessary.

- Cleaning and maintaining tapering tools to ensure optimal performance.

- Keeping work area organized to prevent accidents and facilitate efficient workflow.

- Disposing of waste materials safely and responsibly, adhering to environmental regulations.

4. Troubleshooting and Problem Solving

Unexpected challenges may arise during the tapering process. Bead Wire Tapers must possess problem-solving skills to identify and resolve issues promptly. They analyze situations, consider possible solutions, and implement appropriate measures to maintain productivity.

- Identifying and resolving wire tapering defects, such as irregular tips or uneven lengths.

- Troubleshooting equipment malfunctions and implementing corrective actions.

- Suggesting improvements to the tapering process to enhance efficiency or quality.

Interview Tips

To ace an interview for a Bead Wire Taper position, candidates should prepare thoroughly and present themselves confidently. Here are some tips to help them succeed:

1. Research the Company and Position

Before the interview, candidates should thoroughly research the company, its products or services, and the specific responsibilities of the Bead Wire Taper role. This knowledge demonstrates their interest in the position and readiness to contribute to the organization.

- Visit the company website, read industry news, and gather information about the organization’s values and culture.

- Carefully review the job description to identify the essential skills, experience, and qualifications required for the position.

2. Practice Tapering Techniques

Candidates should practice tapering wire using different tools and techniques to demonstrate their proficiency during the interview. They can bring samples of their work to showcase their skills and attention to detail.

- Practice tapering wire to create various tip shapes and sizes.

- Consider bringing samples of tapered wire or jewelry pieces that highlight their abilities.

3. Emphasize Problem-Solving Abilities

Interviewers seek candidates who can effectively identify and resolve problems. Candidates should prepare examples of situations where they encountered challenges during the tapering process and describe the steps they took to overcome them.

- Recall specific instances where they encountered wire tapering defects or equipment malfunctions.

- Explain the troubleshooting process, including the identification of the root cause and the implementation of solutions.

4. Prepare Questions

Asking thoughtful questions during the interview demonstrates the candidate’s interest and engagement. They should prepare questions that are specific to the role, the company, or the industry. This allows them to clarify any areas of interest and show that they are eager to learn more.

- Prepare questions about the company’s production process or quality control measures.

- Inquire about opportunities for professional development or advancement within the organization.

5. Dress Professionally and Maintain Confidence

First impressions matter. Candidates should dress professionally and maintain a confident demeanor throughout the interview. Non-verbal cues, such as eye contact and a firm handshake, can convey enthusiasm and sincerity. Being well-prepared and confident will increase their chances of making a positive impact on the interviewer.

- Choose attire that is appropriate for an office setting, such as a suit or business casual wear.

- Practice active listening, maintain eye contact, and speak clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bead Wire Taper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!