Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Beam Carrier, Hauler, Pusher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

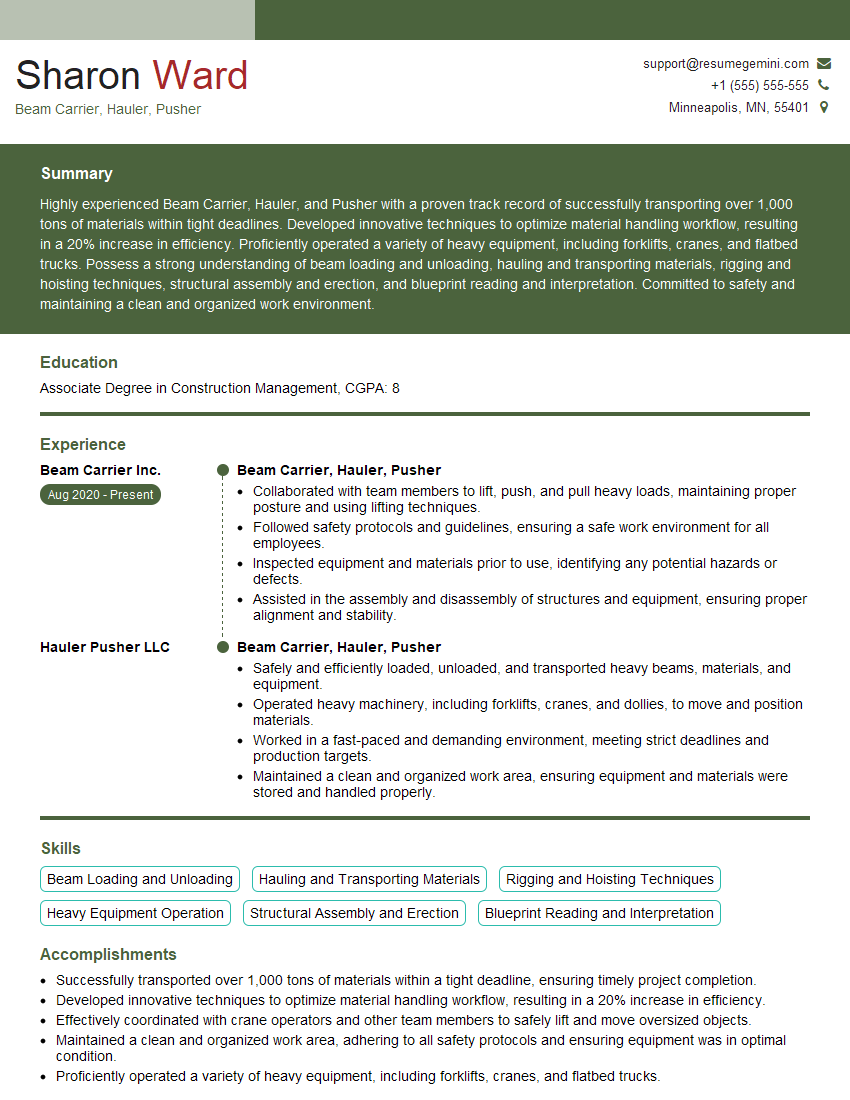

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beam Carrier, Hauler, Pusher

1. How would you ensure the safety of heavy equipment while operating it on a construction site?

To maintain safety while operating heavy equipment on a construction site, I take the following measures:

- Conduct thorough pre-operational inspections to check the equipment’s functionality and identify any potential issues.

- Wear appropriate personal protective gear, such as safety vests, hard hats, and gloves, to minimize risks.

- Establish clear communication with other workers, using hand signals or radios, to ensure coordination and avoid accidents.

- Stay alert and maintain situational awareness, paying attention to the surroundings, potential hazards, and other personnel.

- Adhere to established safety protocols, such as speed limits, load capacities, and designated work zones.

- Undergo regular training and refresher courses to enhance my knowledge and skills in operating heavy equipment safely.

2. Describe the process of loading and unloading materials using a beam carrier.

Loading Materials

- Position the beam carrier correctly and ensure its stability.

- Inspect the beams to verify their weight, size, and condition.

- Use slings or chains to secure the beams properly and prevent them from shifting.

- Operate the crane or hoist to lift the beams and carefully place them onto the beam carrier.

- Secure the beams tightly using straps, chains, or other appropriate methods.

- Check the load’s stability and balance to ensure safe transportation.

Unloading Materials

- Position the beam carrier at the designated unloading area.

- Secure the work area and establish clear communication with other personnel involved in unloading.

- Unload the beams in a controlled manner, using slings, chains, or the crane/hoist.

- Place the beams on the ground or designated storage area.

- Remove the straps, chains, or other securing devices once the beams are safely unloaded.

- Inspect the beams for any damage or defects.

3. What are the primary responsibilities of a hauler operator?

- Operate and maintain heavy-duty haulers to transport materials, equipment, and personnel within construction sites.

- Plan and execute hauling routes to optimize efficiency and minimize risks.

- Inspect haulers regularly and perform routine maintenance tasks to ensure optimal performance.

- Load and unload materials, following established procedures and safety guidelines.

- Monitor load capacities and ensure that the hauler is not overloaded.

- Follow traffic regulations and adhere to designated speed limits and work zone guidelines.

- Communicate effectively with other workers, supervisors, and project managers.

4. Explain the role of a pusher in moving heavy equipment.

A pusher plays a crucial role in moving heavy equipment on construction sites by:

- Positioning themselves behind the equipment to provide additional force.

- Using their body weight and leverage to push the equipment in the desired direction.

- Coordinating with the equipment operator to ensure smooth and safe movement.

- Communicating effectively using hand signals or verbal commands.

- Maintaining situational awareness to avoid obstacles and potential hazards.

5. Describe the factors to consider when calculating load capacities for heavy equipment.

- Equipment specifications, including maximum load capacity and weight distribution.

- Material properties, such as density, weight, and shape.

- Ground conditions, including slope, stability, and soil bearing capacity.

- Environmental factors, such as wind speed and temperature.

- Loading and unloading methods, including equipment used and securing techniques.

- Regulatory requirements and industry standards related to load capacities.

6. What are the common types of slings used for lifting and transporting materials?

- Web slings: Made of synthetic fibers, known for their flexibility and resistance to abrasion.

- Chain slings: Constructed of metal chains, providing high strength and durability.

- Wire rope slings: Comprised of flexible steel wire ropes, offering high tensile strength and resistance to crushing.

- Synthetic round slings: Similar to web slings but made of synthetic fibers with a circular cross-section.

- Specialty slings: Designed for specific applications, such as lifting fragile objects or handling hazardous materials.

7. Explain the importance of proper rigging and load securement for heavy equipment transportation.

Proper rigging and load securement are essential for heavy equipment transportation to:

- Ensure the safety of personnel and equipment during transportation.

- Prevent load shifting and instability, which can lead to accidents.

- Comply with industry regulations and standards related to load securement.

- Minimize damage to equipment and transported materials.

- Facilitate efficient loading and unloading operations.

8. Describe the different types of attachments used on heavy equipment and their applications.

- Buckets: For excavating, digging, and loading materials.

- Forks: For lifting and transporting palletized goods.

- Grapples: For handling and moving irregular or bulky objects.

- Augers: For drilling holes in the ground for foundations or other purposes.

- Hammers: For breaking concrete or driving piles.

- Rippers: For loosening compacted soil or breaking up rock formations.

9. Explain the principles of hydraulic systems used in heavy equipment.

- Pascal’s principle: Pressure applied to a fluid is transmitted equally throughout the fluid.

- Hydraulic pumps: Convert mechanical energy into hydraulic pressure.

- Hydraulic cylinders: Convert hydraulic pressure into linear motion.

- Hydraulic hoses and fittings: Transmit hydraulic fluid under pressure.

- Control valves: Regulate the flow and pressure of hydraulic fluid.

10. Discuss the importance of regular maintenance and inspections for heavy equipment.

- Enhance equipment reliability and performance.

- Prevent breakdowns and minimize downtime.

- Identify and address potential issues before they become major problems.

- Ensure equipment safety and compliance with regulations.

- Extend the lifespan of heavy equipment.

- Reduce operating costs by preventing costly repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beam Carrier, Hauler, Pusher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beam Carrier, Hauler, Pusher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Beam Carriers, Haulers, and Pushers play a crucial role in construction and industrial settings, ensuring the safe and efficient movement of heavy materials.

1. Beam Carriers

Responsible for carrying and transporting beams, girders, and other heavy metal components safely and efficiently.

- Physically carry and handle beams, using appropriate lifting techniques.

- Assist in the placement and alignment of beams during construction or assembly.

2. Haulers

Operate forklifts, cranes, or other heavy equipment to transport and move materials.

- Drive and maneuver equipment safely and efficiently, following established safety protocols.

- Load, unload, and transport materials from one location to another, ensuring proper handling and securing.

3. Pushers

Maneuver and guide heavy construction equipment, such as bulldozers or scrapers, to prepare land or move materials.

- Operate equipment with precision and control, ensuring safety and accuracy.

- Handle and guide equipment through various terrains and obstacles, including slopes and uneven surfaces.

Interview Tips

To ace the interview for a Beam Carrier, Hauler, or Pusher position, candidates should prepare thoroughly and demonstrate their skills and experience effectively.

1. Research and Practice

Thoroughly research the specific job requirements and the company culture. Practice answering common interview questions, such as those related to physical strength, safety protocols, and equipment operation.

- Familiarize yourself with the different types of beams, their weight capacities, and safe handling techniques.

- Understand the principles of load balancing, weight distribution, and proper lifting form.

2. Highlight Physical Fitness and Endurance

Beam Carriers, Haulers, and Pushers require excellent physical fitness and endurance. Emphasize your strength, stamina, and ability to perform physically demanding tasks for extended periods.

- Provide examples of previous jobs or activities where you demonstrated exceptional physical capabilities.

- Discuss your physical training regimen and how it helps you maintain peak condition.

3. Showcase Safety and Attention to Detail

Safety is paramount in these roles. Highlight your commitment to safety standards and your ability to work attentively and follow instructions precisely.

- Explain your knowledge of industry safety regulations and your personal safety practices.

- Describe situations where you identified potential safety hazards and took proactive measures.

4. Emphasize Equipment Operation Skills

If applicable, demonstrate your proficiency in operating relevant heavy equipment. Discuss your experience, certifications, and any special training you have received.

- Highlight your ability to control equipment with precision and maneuver it safely in various conditions.

- Describe your experience in loading, unloading, and transporting materials effectively.

5. Prepare Questions

Ask thoughtful questions that demonstrate your interest in the role and the company. This shows that you are engaged and eager to learn more.

- Inquire about the specific projects or types of materials you would be handling.

- Ask about the company’s safety protocols and training programs.

Next Step:

Now that you’re armed with the knowledge of Beam Carrier, Hauler, Pusher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Beam Carrier, Hauler, Pusher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini